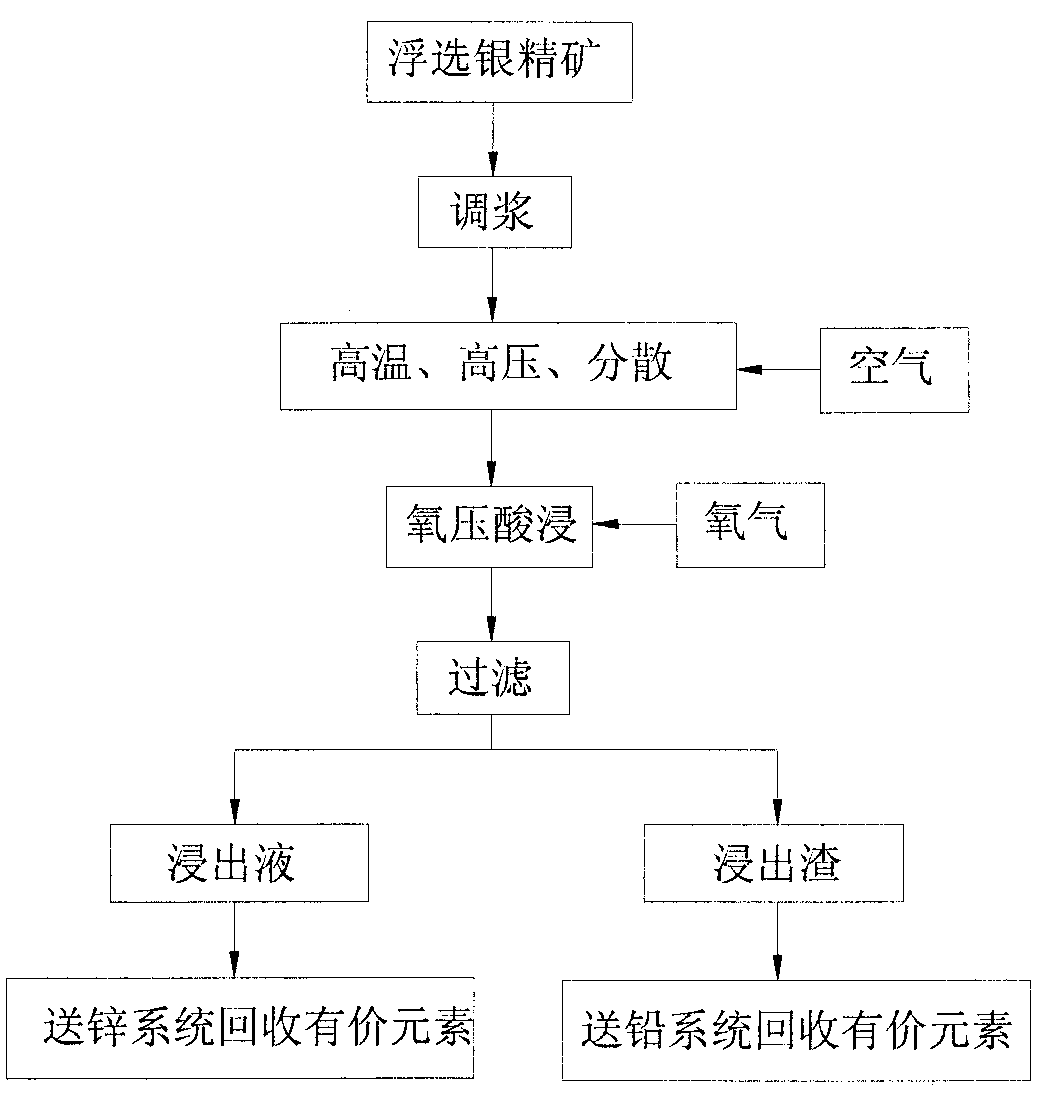

Method for comprehensively recycling zinc, copper, lead, gold, silver and sulfur from floatation silver concentrate

A silver concentrate and copper recovery technology, which is applied in the field of comprehensive recovery of sulfur, copper, silver, lead, zinc, and gold, can solve problems such as low recovery rate, complicated process, and impact on comprehensive recovery benefits, so as to reduce recycling production costs, Improve the effect of economic and technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: A method for comprehensively recovering zinc, copper, lead, gold, silver, and sulfur from flotation silver concentrate, which is the product of conventional hydrometallurgy acid leaching slag after flotation , its composition is: Pb 2~6%, Cu 1~6%, Fe 10~30%, Zn 20~40%, S 15~30%, Au 10~20g / t, Ag 4000~10000g / t, of which , Pb, Cu, Fe, Zn, and S components are weight percentages, and Au and Ag components are weight ratios.

[0023] Among the above Ag components: elemental silver content is 1738-4347 g / t, silver sulfide content is 1992-4981 g / t, silver oxide content is 1-25 g / t, silver content in sulfide is 239-597 g / t, sulfate radical The silver content in the silver is 1-25 g / t, and the silver content in the silicate is 28-70 g / t; among the above-mentioned Zn components: the content of zinc sulfate is 1.21-2.42%, the content of zinc oxide is 1.58-3.16%, and the content of zinc sulfide is 10.13-20.27%, the zinc content in zinc-iron spinel is 7.07-14.14%; amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com