Electrolyzer circumfluence calcination method

An electrolytic cell and roasting technology is applied in the field of roasting and preheating the electrolytic cell, which can solve the problems affecting the normal start-up and production of the electrolytic cell, the inability to conduct timely conduction of high temperature, and the large temperature gradient of the cathode carbon block, etc., so as to improve the roasting effect, The effect of shortening the firing time and avoiding thermal stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

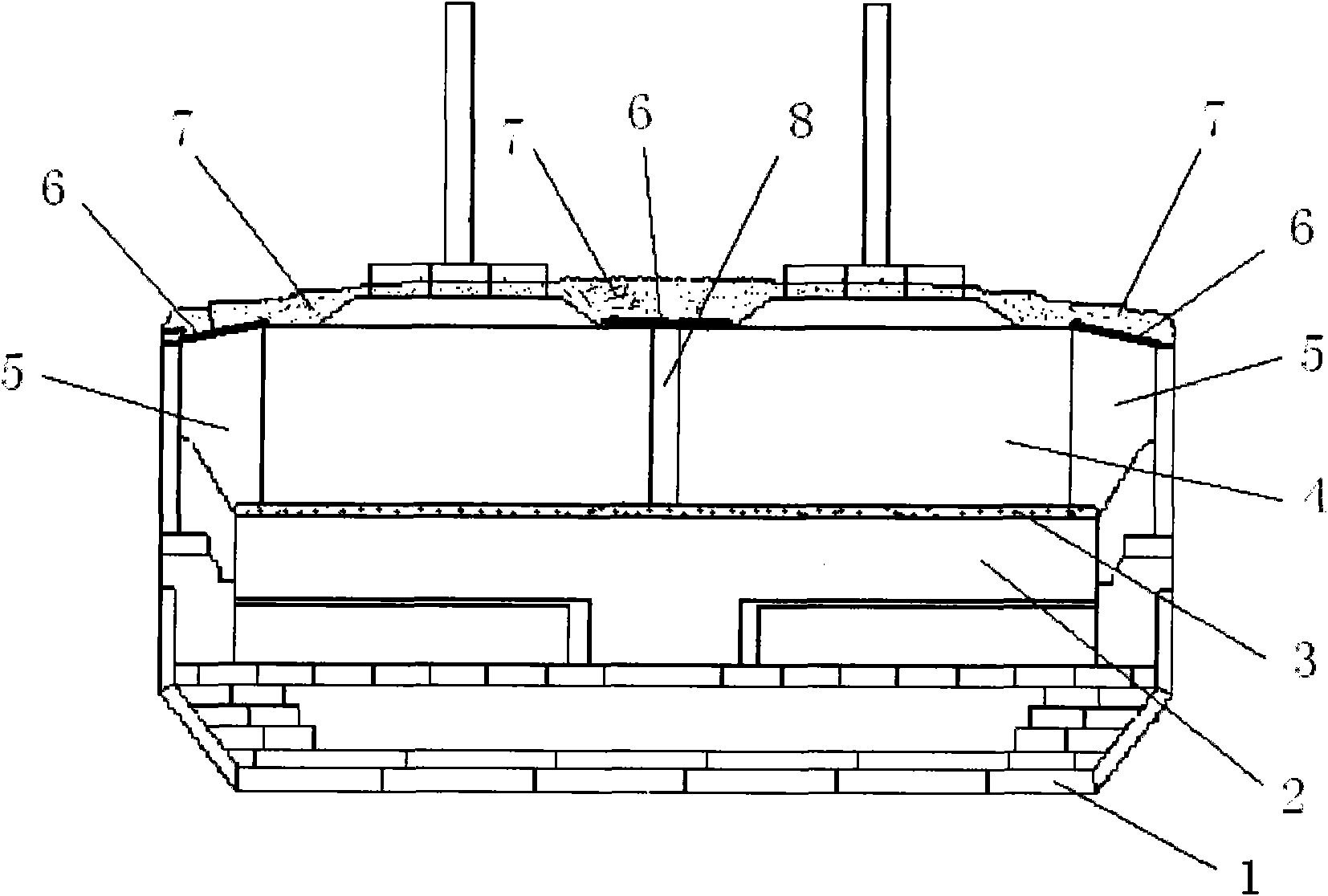

[0023] The electrolytic cell circulation roasting method provided by the present invention comprises the steps of filling the cell and energizing roasting, specifically through the following steps (such as figure 1 shown):

[0024] A. A heating medium layer 3 is laid on the surface of the cathode carbon block 2 in the tank body 1. The thickness of the heating medium layer 3 is 1.8cm, and the material is coke particles. Afterwards, the anode 4 is installed on it, and the anode 4 and the heating medium are ensured. Layer 3 contact is good;

[0025] B, the top of the gap between the anodes 4, the top of the middle slot cavity 8 and the top of the edge cavity 5 are laid with a high temperature resistant insulating and heat insulating layer 6, the thickness of the high temperature resistant insulating and heat insulating layer 6 is 1cm, and the material is Asbestos board, in order to use high-temperature flue gas circulation to evenly roast the entire cathode lining, and at the sa...

Embodiment 2

[0029] The electrolytic cell circulation roasting method provided by the present invention comprises the steps of filling the cell and energizing roasting, specifically through the following steps (such as figure 1 shown):

[0030] A. Lay a heating medium layer 3 on the surface of the cathode carbon block 2 in the tank body 1. The thickness of the heating medium layer 3 is 2.5cm, and the material is graphite. After that, the anode 4 is installed on it, and the anode 4 and the heating medium layer are kept. 3 contacts;

[0031] B, the top of the gap between the anodes 4, the top of the middle slot cavity 8 and the top of the edge cavity 5 are laid with a high-temperature-resistant insulating and heat-insulating layer 6, and the thickness of the high-temperature-resistant insulating and heat-insulating layer 6 is 1.5cm. It is made of aluminum silicate fiberboard, so that the entire cathode lining can be evenly roasted by high-temperature flue gas circulation, and at the same ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com