Separation mineral processing method for molybdenite and galena

A beneficiation method and galena technology, applied in solid separation, flotation and other directions, can solve the problems of heavy metal ions not easily degraded, serious environmental pollution, single effect of pharmaceutical agents, etc., to avoid environmental pollution, simple process, high economic and technical indicators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

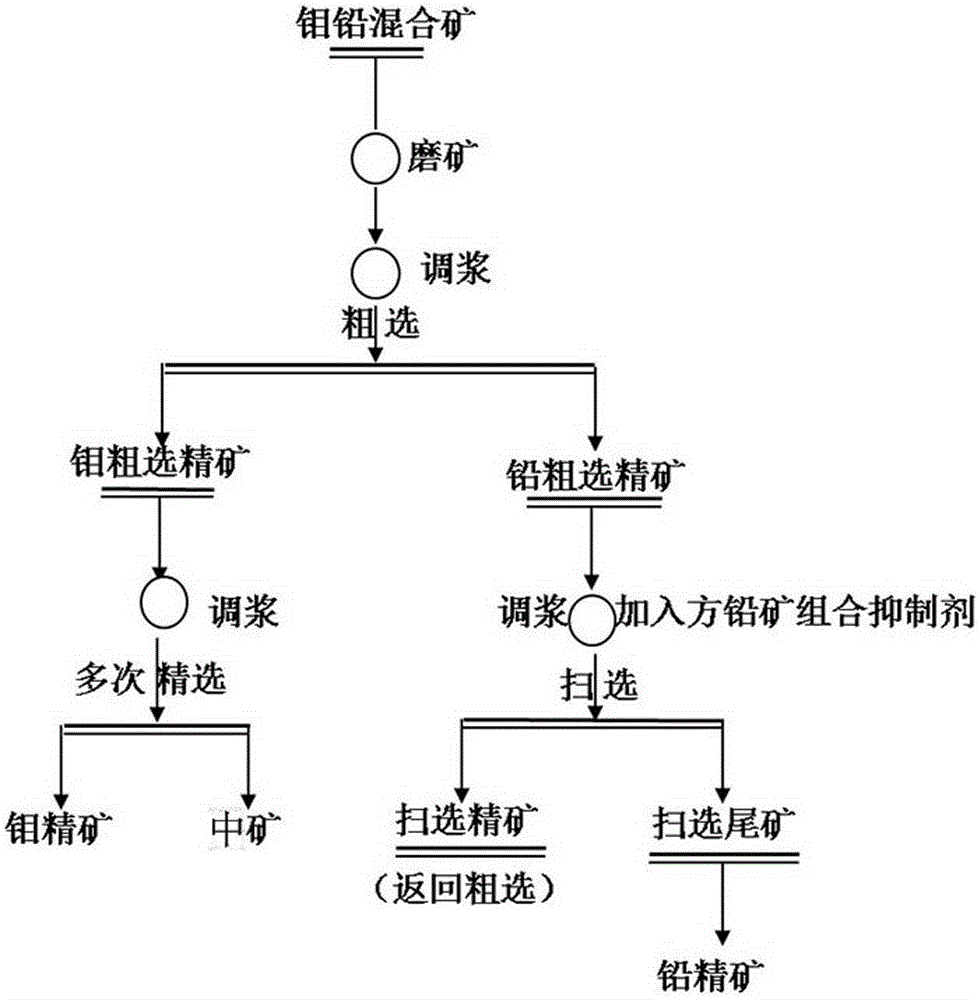

Method used

Image

Examples

Embodiment 1

[0014] Embodiment A pair of molybdenum-lead polymetallic sulfide ore is subjected to flotation separation of molybdenum and lead. In the molybdenum-lead mixed concentrate, the grade of molybdenum is 17.5%, and the grade of lead is 17%. Wherein the separation and dressing steps of molybdenite and galena are:

[0015] 1) Rough separation: Grind molybdenum-lead polymetallic sulfide ore, that is, the raw ore to -0.044 mm, accounting for 90%, adjust the pulp concentration to 30%, add pulp pH regulator and galena combined inhibitor to make the pulp pH = 10, add The galena combination inhibitor is calculated per ton of raw ore: ammonium sulfide 2000g / t, sodium sulfite 1000g / t, sodium metabisulfite 1000g / t, collector kerosene 30g / t, stirring, and molybdenum-lead separation and flotation operation to obtain crude molybdenum Concentrate and lead rougher tailings.

[0016] 2) Sweeping: add galena combination inhibitor to the tailings slurry of roughing lead selection, that is, add ammon...

Embodiment 2

[0020] Raw ore is the same as embodiment one, and the separation ore dressing steps of molybdenite and galena are:

[0021] 1) Rough separation: Grind the molybdenum-lead polymetallic sulfide ore to -0.044 mm to account for 95%, adjust the pulp concentration to 25%, add the pulp pH regulator and galena combined inhibitor to make the pulp pH > 10, add The galena combination inhibitor is calculated per ton of raw ore: ammonium sulfide 1000g / t, sodium sulfite 500g / t, sodium metabisulfite 500g / t, collector kerosene 50g / t, stirring, and molybdenum-lead separation flotation operation to obtain crude molybdenum Concentrate and lead rougher tailings.

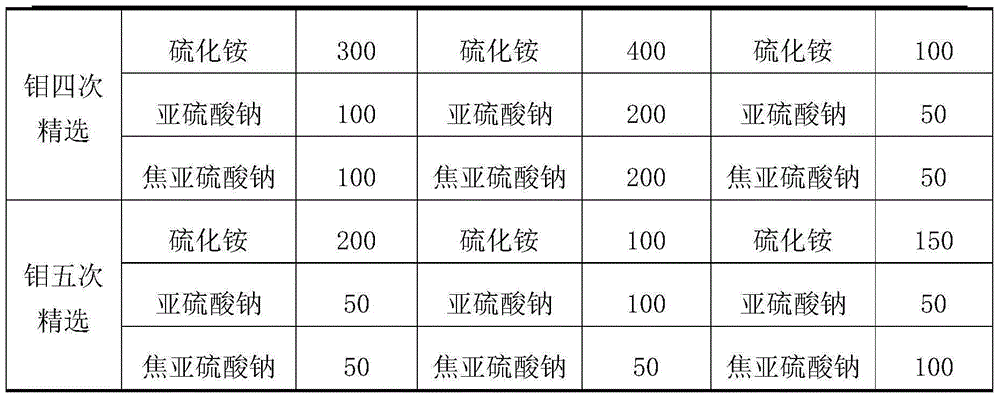

[0022] 2) Sweeping: the amount of galena combined inhibitor added to the tailings slurry of the lead roughing is shown in Table 1, and the rest of the steps are the same as in Example 1.

[0023] 3) Concentration: See Table 1 for the addition amount of galena combination inhibitor for each molybdenum concentrating operation, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com