Prepn of high-purity aluminium chloride

An aluminum chloride and high-purity technology, applied in the direction of aluminum chloride, aluminum halide, etc., can solve problems such as continuous production impact, product quality, and removal difficulties, and achieve easy operation, environmental protection, and high recovery value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

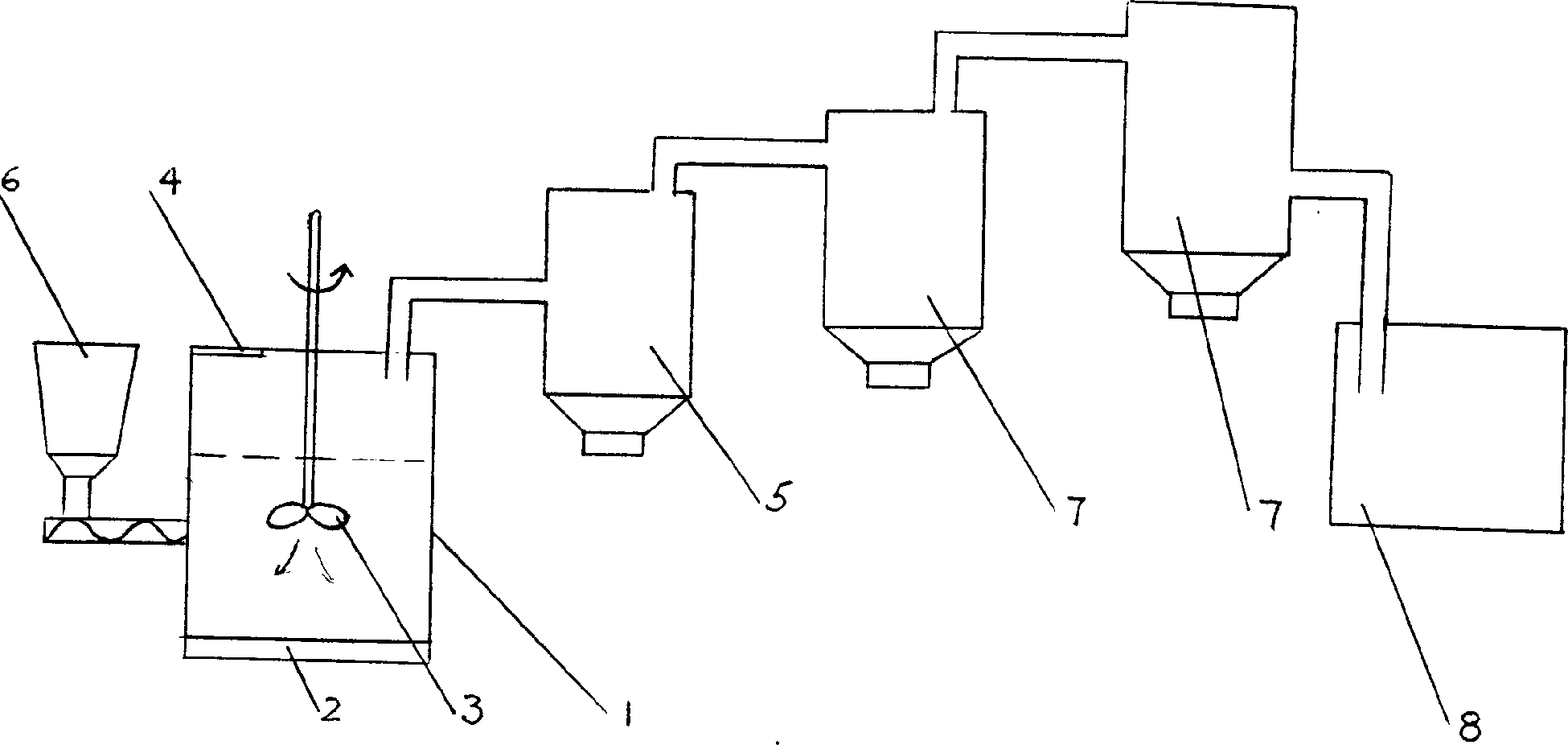

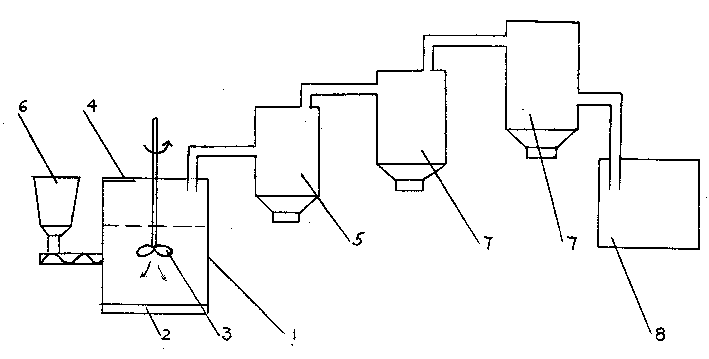

[0035] 70 kilograms of sodium chloride, 120 kilograms of aluminum chloride, and 10 kilograms of sodium fluoride are added into the reaction kettle 1 with an internal diameter of 600 cm and a height of 1800 cm through the feed port 4, heated to 830 degrees with the heating device 2, and the stirring device 3 is started. The speed is 200-300 rpm. After adding 30 kilograms of alumina and 20 kilograms of carbon black at one time, stop heating, and then add 47.75 kilograms of alumina and 8.43 kilograms of carbon black into the reactor 1 at the same speed through the screw conveyor 6, and at the same time, 99.72 kilograms per hour Chlorine gas is added from the center of the stirring shaft 3 at a speed of 125 kg per hour after being filtered through the selective separator 5, and aluminum chloride is recovered from the collector 7, and the carbon dioxide is passed through the tail gas device 8 at a speed of 30.9 kg per hour Discharge after processing.

example 2

[0037] Add 60 kilograms of sodium chloride, 100 kilograms of aluminum chloride, and 8 kilograms of sodium fluoride into the reaction kettle 1 with an inner diameter of 600 cm and a height of 1800 cm through the feed port 4, heat it to 820 degrees with the heating device 2, start the stirring device 3, and stir The speed is 200-300 rpm. After adding 25 kilograms of alumina and 15 kilograms of carbon black at one time, stop heating. Add in the reaction kettle 1 with 38.2 kilograms of aluminum oxides per hour, 6.7 kilograms of carbon black constant speeds by screw conveyor 6 again, add chlorine from stirring 3 axle centers with the speed of 79.8 kilograms per hour simultaneously, after violent reaction, with per hour 100 After the speed of kilogram is filtered by selector separator 5, aluminum chloride is recovered from collector 7, and carbon dioxide is discharged after being treated by tail gas device 8 at a speed of 24.7 kilograms per hour.

[0038] It needs to be specially e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com