Method and device for measuring mass of solid in solid and liquid mixture

A technology for solid-liquid mixtures and mixtures, which is applied in the field of measuring the quality of solids in solid-liquid two-phase mixtures and devices. It can solve the problems of difficult control of stability, large wear of pipe walls, and difficult measurement, and achieves measurement accuracy that is easy to control. , less error influencing factors, controllable effect of the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

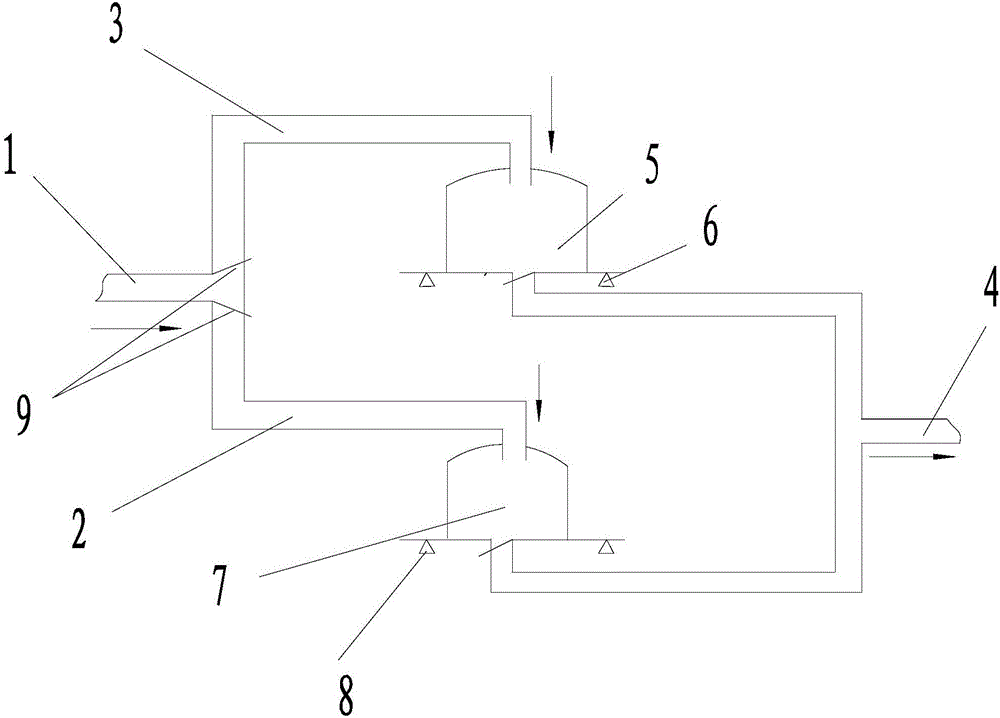

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in combination with specific embodiments.

[0027] A method for measuring the quality of solids in a solid-liquid two-phase mixture, a. first determine the type of solids in the solid-liquid two-phase mixture, and obtain the density P of the solids by looking up a table or an experimental method 固 ;

[0028] b. Measure the solid-liquid two-phase mixture at a volume of V 混 volume V when 混 and mass M 混 ;

[0029] c. According to the volume of the solid-liquid mixture is equal to the sum of the respective volumes of the solid and the liquid; the mass of the solid-liquid mixture is equal to the sum of the respective masses of the solid and the liquid, and the equations are obtained:

[0030] V 混 =V 水 +V 固 Formula 1;

[0031] m 混 = M 水 +M 固 Formula 2;

[0032] Among them, V 水 is the volume of water in the solid-liquid two-phase mixture; V 固 is the volume of the solid in the solid-liquid two-phase mixture; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com