Manufacturing method of light-weight and high-strength water-permeable pavement brick

A manufacturing method and sidewalk technology, which is applied to roads, roads, manufacturing tools, etc., can solve the problems of cushion mortar bonding, poor water absorption, easy loosening, etc., and achieve energy saving for roasting, small bulk density, and not easy loosening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for making lightweight high-strength water-permeable sidewalk bricks, characterized in that the method includes the following steps:

[0021] Mixture preparation: convert the sludge cake, slag and river and lake dried bottom sludge into 0% water content and then prepare according to weight parts. When preparing, add 100kg of sludge cake to every 200kg of slag , adding 500kg of dried river and lake bottom mud, wherein the slag particle size is less than or equal to 2mm, mixed and aged for 1 week, and the moisture content of the mixed material is determined to be equal to 8%, which is used to make road brick blanks;

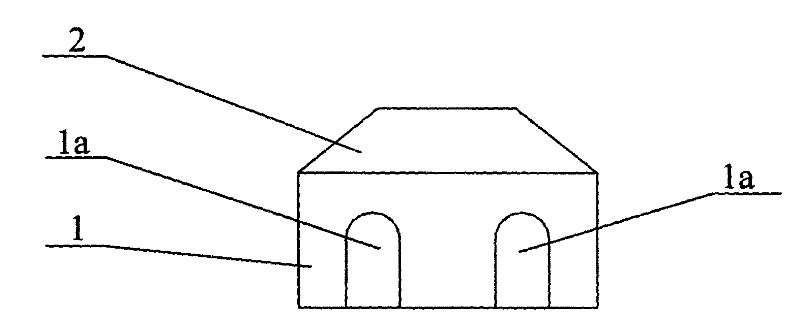

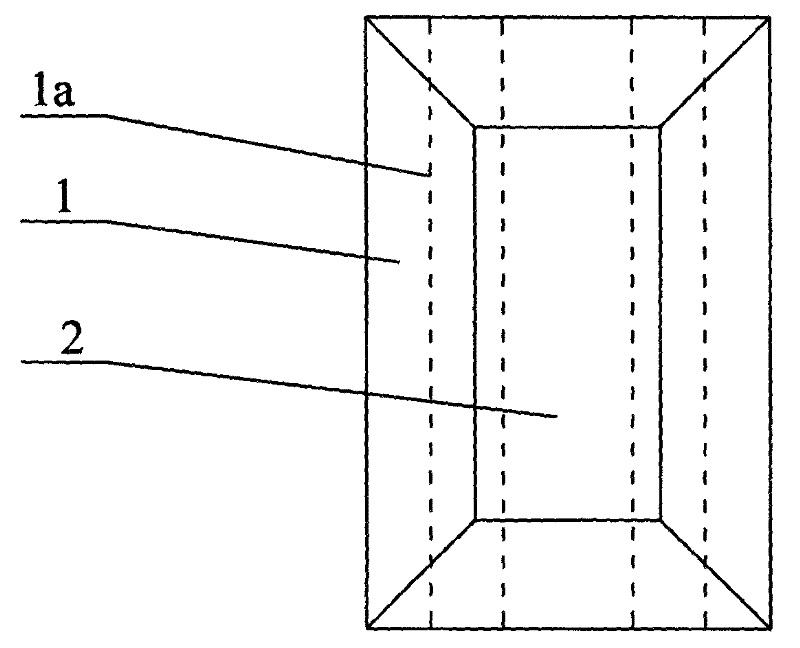

[0022] Road brick molding: fix the ribs on the bottom plate of the mold, add the mixture into the mold cavity, and use the shock pressure road brick press to press the mixture. The shock force of the shock pressure road brick press is controlled at 40KN , the vibration frequency is controlled at 4000 times / min, and the amplitude is controlled at 10m...

Embodiment 2

[0030] A method for making lightweight high-strength water-permeable sidewalk bricks, characterized in that the method includes the following steps:

[0031] Mixture preparation: convert the sludge cake, slag and river and lake dried bottom sludge into 0% water content and then prepare according to weight parts. When preparing, add 300kg of sludge cake to every 200kg of slag , adding 700kg of dried river and lake bottom mud, wherein the slag particle size is less than or equal to 2mm, mixed and aged for 2 weeks, and the water content of the mixed material was determined to reach 16%, which was used to make road brick blanks;

[0032] Road brick molding: fix the ribs on the bottom plate of the mold, add the mixture into the mold cavity, and use the shock pressure road brick press to press the mixture. The shock force of the shock pressure road brick press is controlled at 68KN , the vibration frequency is controlled at 5000 times / min, and the amplitude is controlled at 15mm;

...

Embodiment 3

[0040] A method for making lightweight high-strength water-permeable sidewalk bricks, characterized in that the method includes the following steps:

[0041] Mixture preparation: convert the sludge cake, slag and river and lake dried bottom sludge into 0% water content and then prepare according to weight parts. When preparing, add 200kg of sludge cake to every 200kg of slag , add 600kg of river and lake dried bottom mud, wherein the slag particle size is less than or equal to 2mm, mix and age for 10 days, measure the moisture content of the mixture to 12%, and use it to make road brick blanks;

[0042] Road brick molding: fix the ribs on the bottom plate of the mold, add the mixture into the mold cavity, and use the shock pressure road brick press to press the mixture. The shock force of the shock pressure road brick press is controlled at 50KN , the vibration frequency is controlled at 4300 times / min, and the amplitude is controlled at 13mm;

[0043] Drying: natural air-dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com