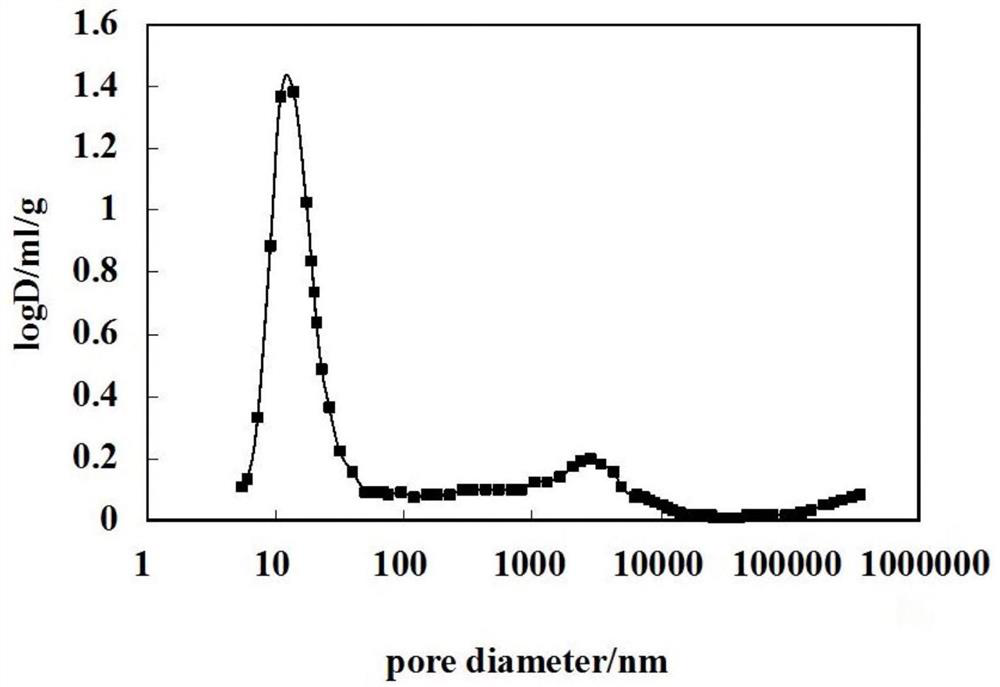

Coal tar bimodal pore structure hydrogenation pretreatment catalyst and preparation method thereof

A technology for hydrogenation pretreatment and hydrogenation catalyst, which is applied in the directions of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. Problems such as secondary pollution are generated, and the effects of reducing roasting energy consumption, high proportion of macropores, and improving carrier strength are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

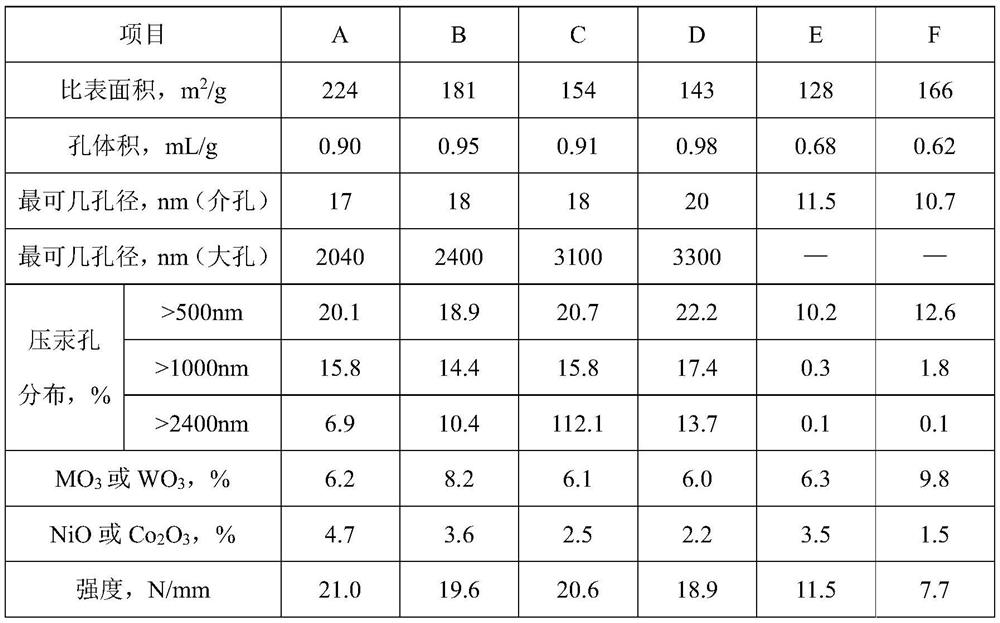

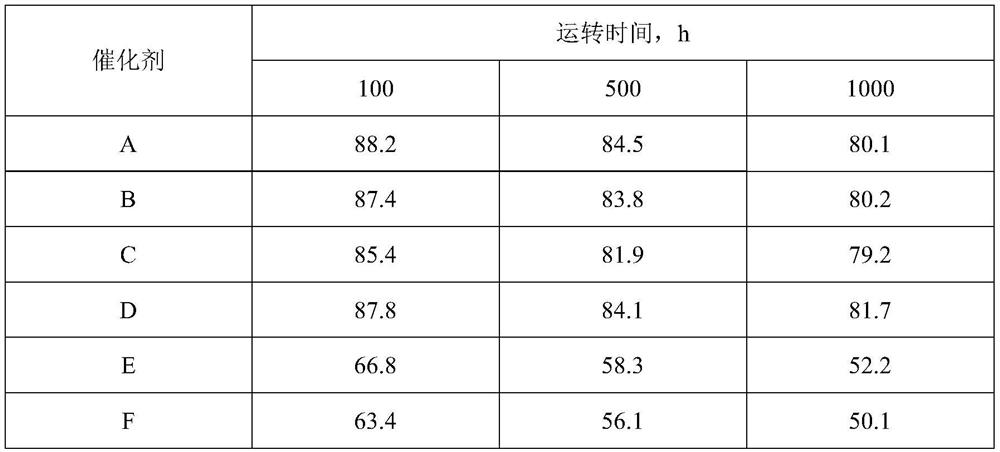

Examples

Embodiment 1

[0042] Preparation of phosphorus-containing pseudoboehmite M 1 and M 2 ,M 1 Contains 1.38% of its total weight of P, M 2 Contains 1.69% of P in its total weight. Determination of specific surface area and pore volume of phosphorus-containing pseudo-boehmite by nitrogen adsorption method, M 1 The specific surface area is 184m 2 / g, the pore volume is 2.1mL / g, and the most probable pore diameter is 40.8nm; M 2 The specific surface area is 420m 2 / g, the pore volume is 1.3mL / g, and the most probable pore diameter is 18.6nm. Weigh the above-mentioned phosphorus-containing pseudo-boehmite M 1 50g (dry basis), phosphorus-containing pseudo-boehmite M 2 50g (dry basis), add 3g of asparagus powder, dissolve 1.8g of boric acid and 0.8g of polyoxyethylene ether in 110g of deionized water, add to the aforementioned materials, knead and extrude into a cylinder with a diameter of 2.5mm on a single-screw extruder shape, dried at 105°C for 4 hours, and then calcined at 800°C for 4 ...

Embodiment 2

[0044] Preparation of phosphorus-containing pseudoboehmite M 1 and M 2 ,M 1 Contains 0.87% of its total weight of P, M 2 Contains 0.96% of P in its total weight. Determination of specific surface area and pore volume of phosphorus-containing pseudo-boehmite by nitrogen adsorption method, M 1 The specific surface area is 178m 2 / g, the pore volume is 2.2mL / g, and the most probable pore diameter is 34.6nm; M 2 The specific surface area is 400m 2 / g, the pore volume is 1.3mL / g, and the most probable pore diameter is 17.0nm.

[0045] Weigh the above-mentioned phosphorus-containing pseudo-boehmite M 1 60g (dry basis), phosphorus-containing pseudo-boehmite M 2 40g (dry basis), add 3g of safflower powder and 2.0g of boron oxide, dissolve 1.0g of polyoxyethylene ether in 107g of deionized water, add to the aforementioned materials, knead and extrude on a single-screw extruder into diameter 3.0mm Four-leaf clover shape, dried at 120°C for 3 hours, and then calcined at 600°C fo...

Embodiment 3

[0047] Preparation of phosphorus-containing pseudoboehmite M 1 and M 2 ,M 1 Contains 1.78% of its total weight of P, M 2 Contains 0.54% of P in its total weight. Determination of specific surface area and pore volume of phosphorus-containing pseudo-boehmite by nitrogen adsorption method, M 1 The specific surface area is 230m 2 / g, the pore volume is 3.0mL / g, and the most probable pore diameter is 21.5nm; M 2 The specific surface area is 410m 2 / g, the pore volume is 1.4mL / g, and the most probable pore diameter is 18.0nm.

[0048] Weigh the above-mentioned phosphorus-containing pseudo-boehmite M 1 70g (dry basis), phosphorus-containing pseudo-boehmite M 2 30g (dry basis), add 3g of asparagus powder, dissolve 1.6g of boric acid and 1.4g of polyoxyethylene ether in 110g of deionized water, add to the aforementioned materials, knead and extrude into a clover with a diameter of 3.0mm on a single-screw extruder shape, dried at 110°C for 4 hours, and then calcined at 750°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com