Device and method for selective roasting-magnetic separation of fine-grained ilmenite

A technology of ilmenite and fine particles, applied in chemical instruments and methods, magnetic separation, process efficiency improvement, etc., can solve the problems of strong magnetic field force and difficult to obtain effective recovery, etc., achieve rapid response, easy automatic operation, energy The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

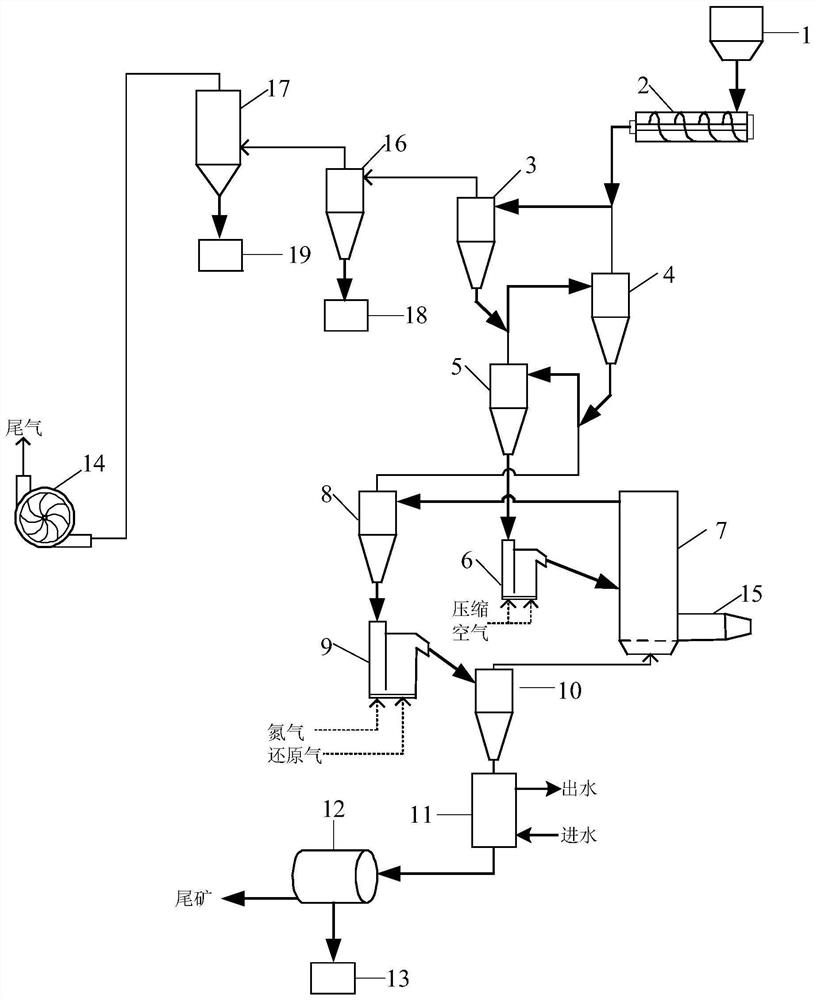

[0047] The device structure of selective roasting-magnetic separation of fine-grained ilmenite is as follows figure 1 As shown, it includes silo 1, primary cyclone preheater 3, secondary cyclone preheater 4, tertiary cyclone preheater 5, oxidation reactor 6, suspension heating furnace 7, first cyclone separator 8, reduction Reactor 9, second cyclone separation drum 10, water-cooled heat exchanger 11 and weak magnetic separator 12;

[0048] The discharge port of the silo 1 is opposite to the feed port of the screw feeder 2. The discharge port of the screw feeder 2 is connected with the feed port of the first-stage cyclone preheater 3 through a pipeline, and the first-stage cyclone preheater The discharge port of 3 is communicated with the feed port of the secondary cyclone preheater 4 through a pipeline, and the discharge port of the secondary cyclone preheater 4 is communicated with the feed port of the third-stage cyclone preheater 5 through a pipeline;

[0049] The discharg...

Embodiment 2

[0069] The device structure of the selective roasting-magnetic separation of fine-grained ilmenite is the same as that in Example 1;

[0070] The method is the same as in Example 1, except that:

[0071] (1) Fine-grained ilmenite iron grade TFe 14.88%, containing TiO by weight 2 8.89%, SiO 2 34.86%, Al 2 O 3 12.85%, CaO 9.12%, MgO 9.73%, the part with particle size less than 0.038mm in the solid part accounts for 90% of the total mass;

[0072] (2) The volume flow ratio of natural gas and air introduced into the burner 15 per unit time is 1:19;

[0073] (3) The temperature of the preheated ilmenite in the oxidation reactor 6 for the preoxidation reaction is 600°C, and the ratio of the volume flow of the air entering the oxidation reactor 6 to the mass flow of the preheated ilmenite is 0.25 m 3 / kg

[0074] (4) The temperature of the oxide material is 750°C;

[0075] (5) the temperature of the solid material when the reduction reaction is carried out in the reduction r...

Embodiment 3

[0079] The device structure of the selective roasting-magnetic separation of fine-grained ilmenite is the same as that in Example 1;

[0080] The method is the same as in Example 1, except that:

[0081] (1) Fine-grained ilmenite iron grade TFe 11.26%, containing TiO by weight 2 9.29%, SiO 2 38.15%, Al 2 O 3 9.13%, CaO 7.24%, MgO 10.26%, the part with particle size less than 0.038mm in the solid part accounts for 65% of the total mass;

[0082] (2) The volume flow ratio of natural gas and air introduced into the burner 15 per unit time is 1:21;

[0083] (3) The temperature of the preheated ilmenite in the oxidation reactor 6 for the pre-oxidation reaction is 500°C, and the ratio of the volume flow of the air entering the oxidation reactor 6 to the mass flow of the preheated ilmenite is 0.22 m 3 / kg

[0084] (4) The temperature of the oxide material is 650°C;

[0085] (5) the temperature of solid material when reduction reactor 9 carries out reduction reaction is 500 ℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com