Carbonate/silicon oxide compound gel adsorbent and preparation method thereof

A composite gel and carbonate technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., to achieve the effect of simple preparation principle and process, wide range of sources, high specific surface area and pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

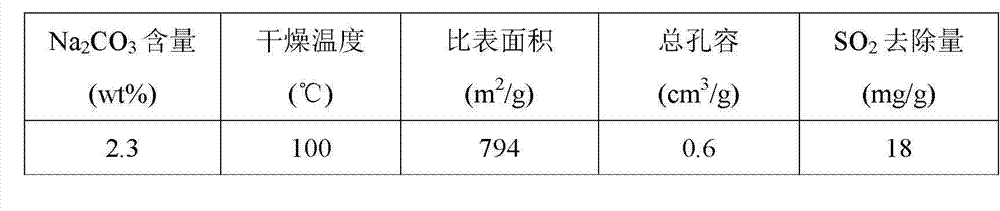

Embodiment 1

[0022] Put 52g of TEOS, 69g of EtOH and 18g of deionized water into a 250mL beaker, stir them with magnetic force at 30°C for 120 min to make them evenly mixed, and quickly drop 0.033mL of hydrochloric acid with a concentration (mass fraction) of 5% into the above beaker and stirred at 20°C for 12 h, then aged for 120 h to obtain SiO 2 Sol; 25 g Na 2 CO 3 Add to a 250 mL volumetric flask, add deionized water to volume, and obtain a Na concentration of 100 g / L 2 CO 3 solution; 3.5 mL of the above 100 g / L Na 2 CO 3 The solution was added to the prepared SiO 2 In the sol, stir until it is completely gelled, add EtOH to soak the gel, make it aged for 108 h, and dry naturally at 80 °C for 4 h to obtain Na 2 CO 3 The mass fraction is 2.3% Na 2 CO 3 / SiO 2 Composite xerogel; the xerogel obtained above was placed in a constant temperature drying oven, and treated at 200°C for 8 h to obtain Na 2 CO 3 The mass fraction is 2.3% Na 2 CO 3 / SiO 2 Composite Gel Chemisorbent. ...

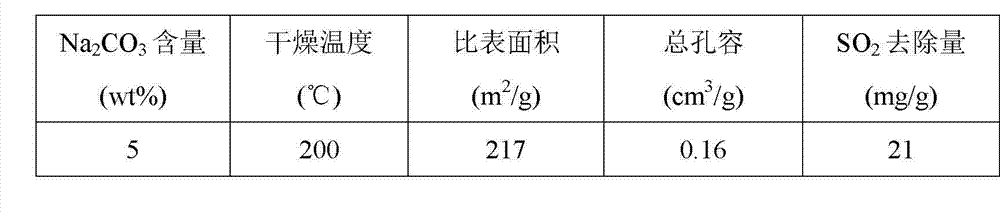

Embodiment 2

[0027] Put 52g TEOS, 11.5 g EtOH and 4.5 g deionized water into a 250mL beaker, stir magnetically at 20°C for 30min to mix evenly, and mix 1.825×10 -3 The hydrochloric acid with a concentration (mass fraction) of 5% was quickly added dropwise to the above beaker and stirred at 20 °C for 12 h, and then aged for 120 h to obtain SiO 2 Sol; 50 g Na 2 CO 3 Add it to a 250 mL volumetric flask, add deionized water to volume, and obtain a Na concentration of 200 g / L 2 CO 3 solution; 3.95 mL of the above 200 g / L Na 2 CO 3 The solution was added to the prepared SiO 2 In the sol, stir until it is completely gelled, add EtOH to soak the gel, make it aged for 72 h, and dry it naturally at 80°C for 6 h to obtain Na 2 CO 3 The mass fraction is 5% Na 2 CO 3 / SiO 2 Composite xerogel; the xerogel obtained above was placed in a constant temperature drying oven, and treated at 200°C for 8 h to obtain Na 2 CO 3 The mass fraction is 5% Na 2 CO 3 / SiO 2 Composite Gel Chemisorbent.

...

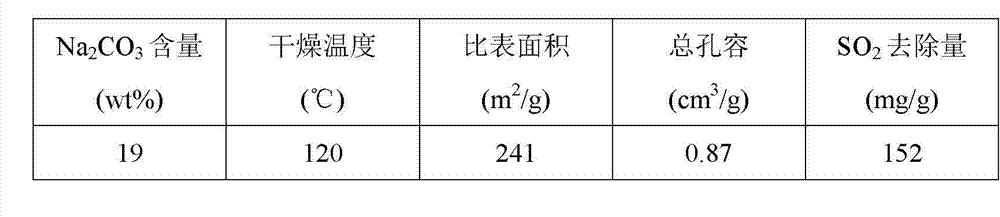

Embodiment 3

[0032] Put 52 g TEOS, 69 g EtOH and 18 g deionized water into a 250 mL beaker, stir magnetically at 25 °C for 60 min to mix evenly, add 0.03 mL of 37% hydrochloric acid dropwise to the above beaker and stir at 25 °C 120 min, and aged for 6h, to get SiO 2 Sol; 25 g Na 2 CO 3 Add to a 250 mL volumetric flask, add deionized water to volume, and obtain a Na concentration of 100 g / L 2 CO 3 solution; 35 mL of Na with a concentration of 100 g / L 2 CO 3 The solution was added to the prepared SiO2 In the sol, stir until it is completely gelled, add EtOH to soak the gel, make it aged for 144 h, and dry at 80°C for 5 h to obtain Na 2 CO 3 The mass fraction is 19% Na 2 CO 3 / SiO 2 Composite xerogel; the xerogel obtained above was placed in a constant temperature drying oven, and dried at 120°C for 12 h to obtain Na 2 CO 3 The mass fraction is 19% Na 2 CO 3 / SiO 2 Composite Gel Chemisorbent.

[0033] 0.04 g of the composite gel chemisorbent obtained in this experiment was sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com