A split-type filling block continuous prebaked anode carbon block

A prebaked anode and filling block technology, which is applied in the field of prebaked anode carbon blocks in aluminum electrolytic cells, can solve the problems of high working environment temperature, large waste of carbon materials, and increased resistance of anode carbon blocks, and achieve low installation accuracy requirements, High effective filling rate and reduced unit cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

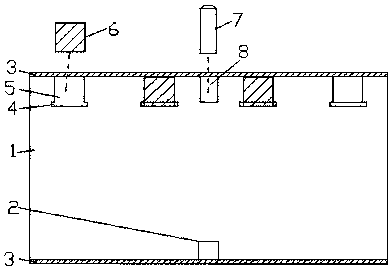

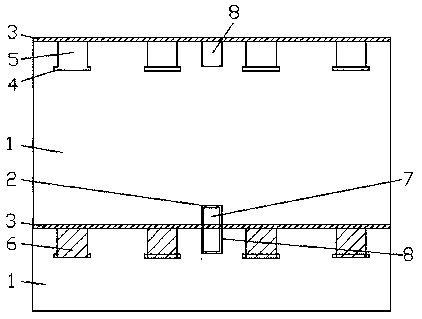

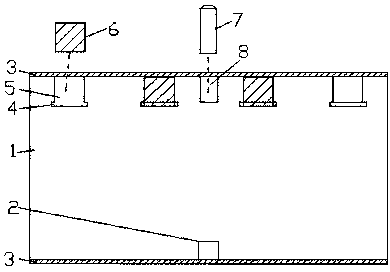

[0028] Example. A continuous prebaked anode carbon block of a split packing block, which is composed of Figure 1-2 As shown, include a carbon block body 1, the carbon block body 1 is provided with a charcoal bowl 5, and the activity in the charcoal bowl 5 is provided with a charcoal bowl filling block 6, and the upper end surface of the charcoal bowl filling block 6 in the charcoal bowl 5 and the charcoal bowl 5 The top surface is even.

[0029] The carbon block body 1 at the bottom of the carbon bowl 5 is provided with a mechanical steel claw connecting ring groove 4 .

[0030] The upper center of the carbon block body 1 is movably connected to the convex head 7 via the bonding groove 8 of the connecting convex head.

[0031] A connection groove 2 is provided in the middle of the bottom of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com