Method for preparing cementing material from suspended roasted coal gasifying slag

A technology of cementitious materials and coal gasification slag, which is applied in the direction of cement production, etc., can solve the problems of insufficient consumption of coal gasification slag, limited processing capacity, difficult removal, etc., achieve good economic and social benefits, and save roasting energy consumption , The effect of less pollution discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

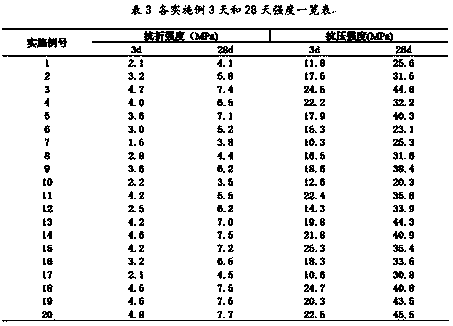

[0017] The present invention will be further described in detail through specific examples below, but the present invention is not limited thereto.

[0018] It should be noted that the "coal gasification slag" in this article refers to various gasification ash obtained after being treated in various gasification furnaces in the form of coal-water slurry or coal powder, but is not limited to the above-mentioned gasification ash, and is also applicable to Other process by-products must contain carbon-containing ash.

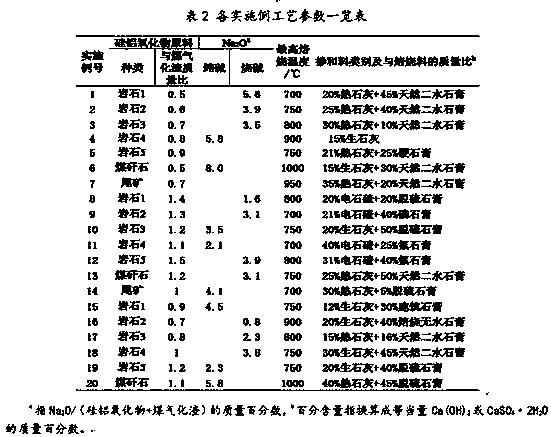

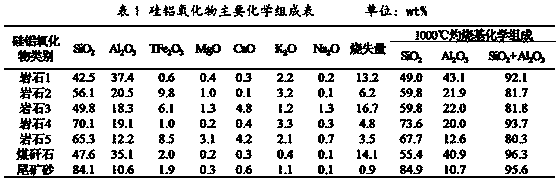

[0019] The silicon-aluminum oxide involved in the embodiment has 5 kinds of natural rocks, a kind of coal gangue and a kind of mine tailings, and their main chemical composition is shown in Table 1; Industrial alkali has used NaOH and NaOH 2 CO 3 , both of which are analytically pure; the lime used includes quicklime, slaked lime and carbide slag, and the former two are analytically pure CaO and Ca(OH) 2 , while calcium carbide slag contains 85% (mass ratio) of C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com