Semi-internal combustion type red mud sintered brick and production process and application

A production process and sintered brick technology, which is applied to semi-internal combustion red mud sintered bricks and its production process and application fields, can solve the problems of heavy metal dissolution and emissivity level increase, and achieve reduction of roasting energy consumption, easy operation of production process, and radioactivity The effect of level reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

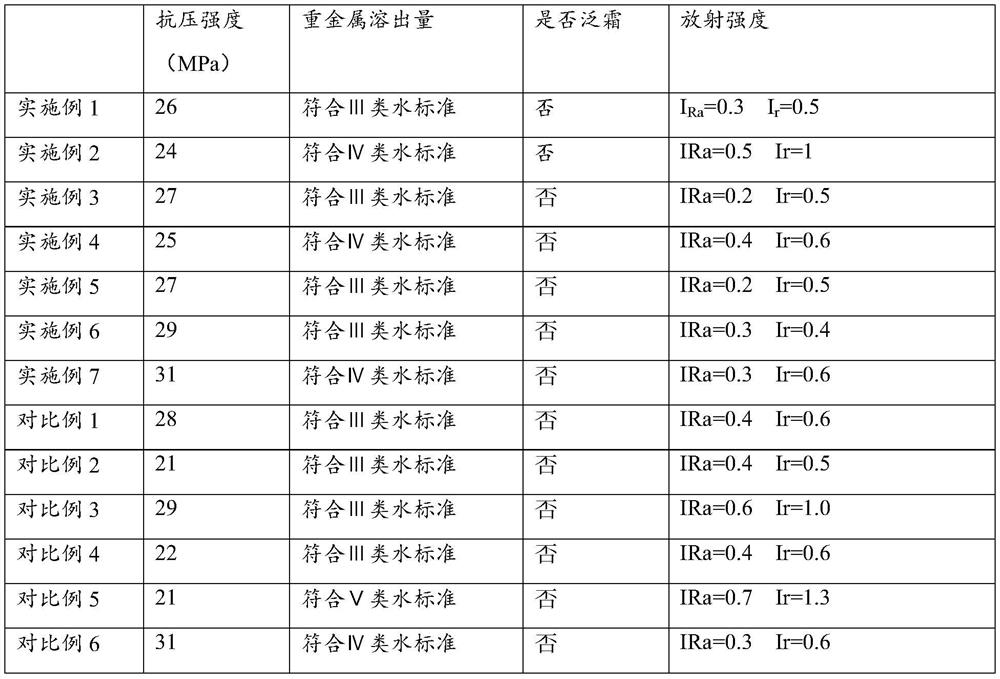

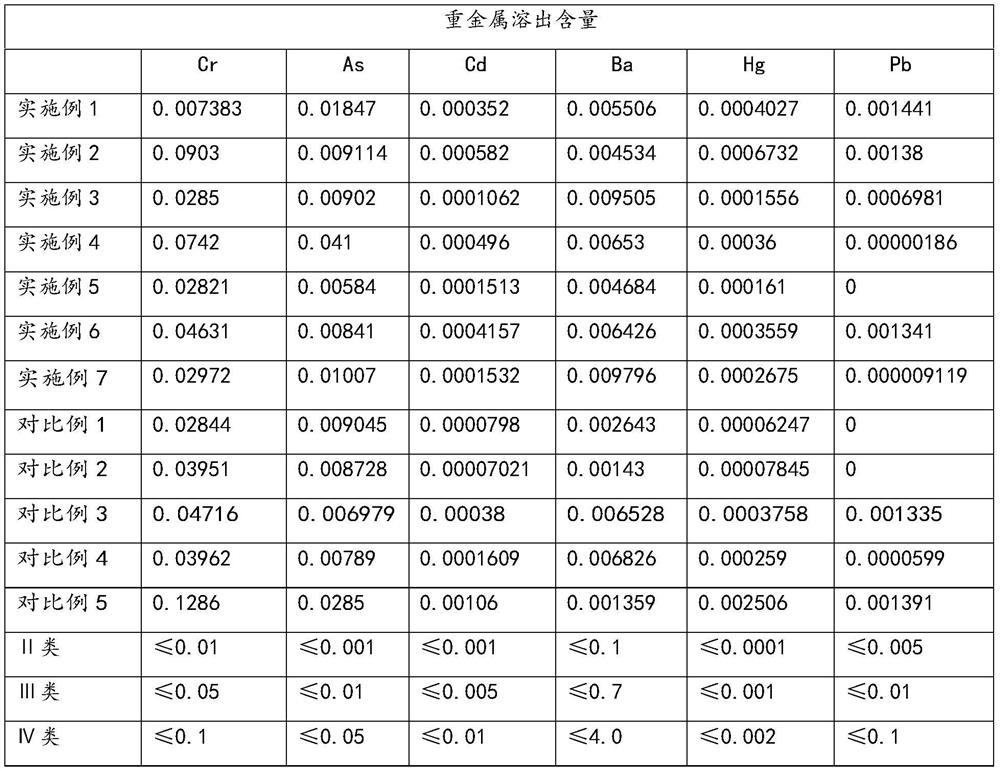

Examples

Embodiment 1

[0072] This embodiment provides a semi-internal combustion red mud sintered brick, which is made of the following components in parts by mass: 20 parts of Bayer process red mud, 5 parts of plastic clay, 20 parts of coal gangue, and 40 parts of aggregate , 5 parts of flux, 7 parts of binder and 3 parts of radioactive shielding agent, wherein the particle size of Bayer process red mud, flux, aggregate and plastic clay is ≤200 mesh; the particle size of coal gangue is ≤100 mesh, and plastic clay is Kaolin, the aggregate is broken porcelain particles, the flux is waste glass powder, the binder is sodium silicate aqueous solution, and the radioactive shielding agent is barium sulfate.

Embodiment 2

[0074] This embodiment provides a semi-internal combustion red mud sintered brick, which is made of the following components in parts by mass: 60 parts of Bayer process red mud, 5 parts of plastic clay, 15 parts of coal gangue, and 10 parts of aggregate , 5 parts of flux, 3 parts of binder and 2 parts of radioactive shielding agent, wherein the particle size of Bayer process red mud, aggregate and plastic clay is ≤200 mesh; the particle size of coal gangue is ≤100 mesh, plastic clay, aggregate, The flux, adhesive and radioactive shielding agent are the same as those in Example 1, and will not be repeated here.

Embodiment 3

[0076] This embodiment provides a semi-internal combustion red mud sintered brick, which is made of the following components in parts by mass: 30 parts of Bayer process red mud, 15 parts of plastic clay, 20 parts of coal gangue, and 15 parts of aggregate , 10 parts of flux, 5 parts of binder and 5 parts of radioactive shielding agent, wherein the particle size of Bayer process red mud, aggregate and plastic clay is ≤200 mesh; the particle size of coal gangue is ≤100 mesh, plastic clay, aggregate, The flux, adhesive and radioactive shielding agent are the same as those in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com