Method for recycling gold for gold-bearing washing mud of gold ore cyaniding system

A cyanidation system and gold recovery technology, applied in the field of metallurgy, can solve the problems of equipment cost, high energy consumption, large investment in microwave equipment, long biological oxidation time, etc., and achieve low production cost, efficient recovery, and prevention of secondary wrapping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

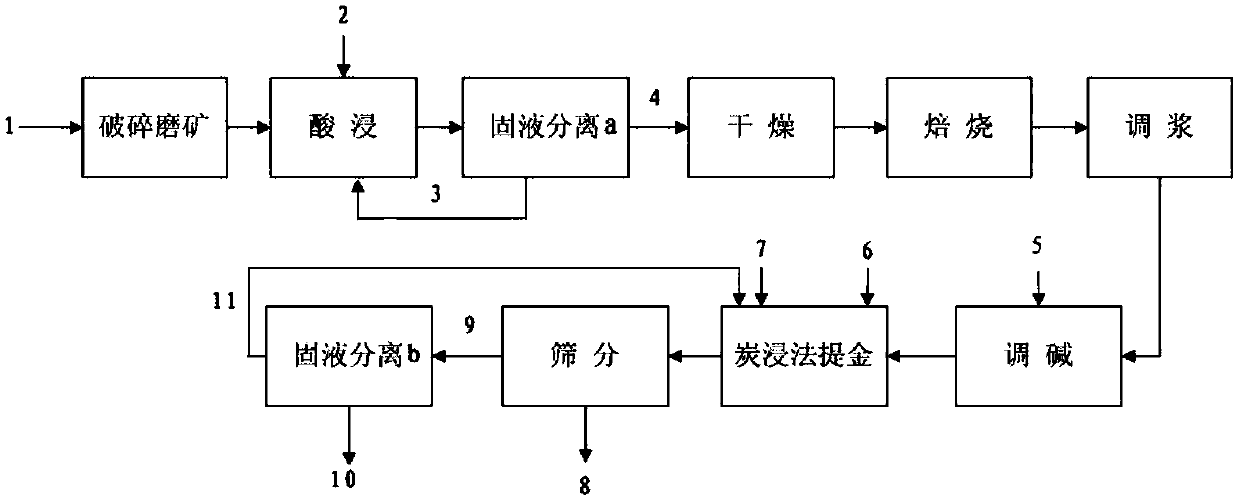

[0044] Example 1: The gold-containing washing mud of the gold mine cyanidation system is crushed, and the fineness after fine grinding reaches -200 mesh, accounting for 80%; The concentration is 10kg / m3, and the acid leaching time is 2h; the acid leaching pulp is subjected to solid-liquid separation, and the acid leaching residue is washed with water until the pH of the washing solution is close to neutral and dry; high temperature roasting is carried out at 500 ℃, and the roasting time is 1h; Add water to make ore pulp with a solid content of 35%, and adjust the pH of the ore pulp to 9 with sodium hydroxide; add 3kg / t of NaCN (dry slag) and 20kg / m3 of activated carbon (ore pulp) to the ore pulp to extract gold by charcoal. The leaching time is 20h; the pulp after carbon leaching gold is separated with a 20-mesh sieve, the product on the sieve is the product gold-loaded carbon, and the material under the sieve is subjected to solid-liquid separation. stockpiled.

[0045] The ...

example 2

[0046]Example 2: The gold-containing washing mud of the gold mine cyanidation system is crushed, and the fineness after fine grinding reaches -200 mesh, accounting for 85%; 50 g of gold-containing washing mud is acid leached with hydrochloric acid, and the liquid-solid ratio is 3:1, and the hydrochloric acid is 3:1. The concentration is 20kg / m3, and the acid leaching time is 3h; the acid leaching pulp is separated from the solid-liquid, and the acid leaching residue is washed with water until the pH of the washing solution is close to neutral and dry; high temperature roasting is carried out at 600 ℃, and the roasting time is 2 hours; Add water to adjust the ore pulp with a solid content of 40%, and adjust the pH of the ore pulp to 11 with sodium hydroxide; add 5kg / t of NaCN (dry slag) and 30kg / m3 of activated carbon (ore pulp) to the ore pulp to extract gold by carbon. The leaching time is 24h; the pulp after carbon leaching gold is separated with a 20-mesh sieve, the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com