Continuous pre-baked anode carbon block with split type independent carbon bowl and ultra-long filling block structure

A technology of prebaked anode and independent carbon, which is applied in the field of split independent carbon bowl and super-long filling block structure continuous prebaked anode carbon block, which can solve the problems of large waste of carbon materials, increased resistance of anode carbon block, and heat loss, etc. , to achieve the effects of reduced production cost, reduced unit cost, and high effective filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

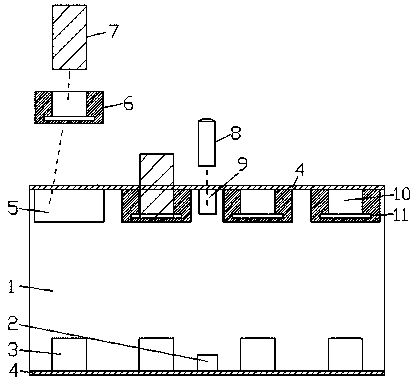

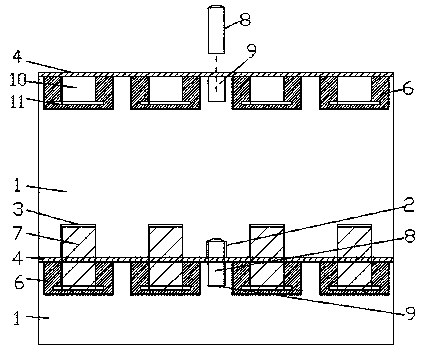

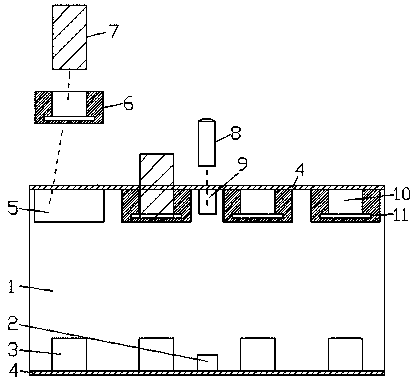

[0030] Example. A split-type independent carbon bowl, super-long filling block structure continuous prebaked anode carbon block, constituted as Figure 1-2 As shown, a carbon block body 1 is included, and the carbon block body 1 is provided with a carbon bowl assembly connection pit 5, and a charcoal bowl assembly 6 is arranged in the charcoal bowl assembly connection pit 5, and a charcoal bowl assembly 6 is provided with There is a charcoal bowl 10, the charcoal bowl assembly 6 at the bottom of the charcoal bowl 10 is provided with a mechanical steel claw connection ring groove 11, and the activities in the charcoal bowl 10 on the charcoal bowl assembly 6 are provided with super long charcoal bowl filling blocks 7.

[0031] The carbon bowl assembly contains 0.5-5% carbon fiber.

[0032] The middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com