Method utilizing alunite in flotation tailing to produce potassium sulfate and auxiliary products thereof

A technology of flotation tailings and alunite, which is applied in the direction of sulfate/bisulfate preparation, etc., can solve the problems of low potash fertilizer output and self-sufficiency rate, low level of comprehensive utilization of tailings, insufficient potash fertilizer self-sufficiency rate, etc., and achieve the improvement of comprehensive The effect of utilization level, shortening reduction roasting time, and reducing plant floor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

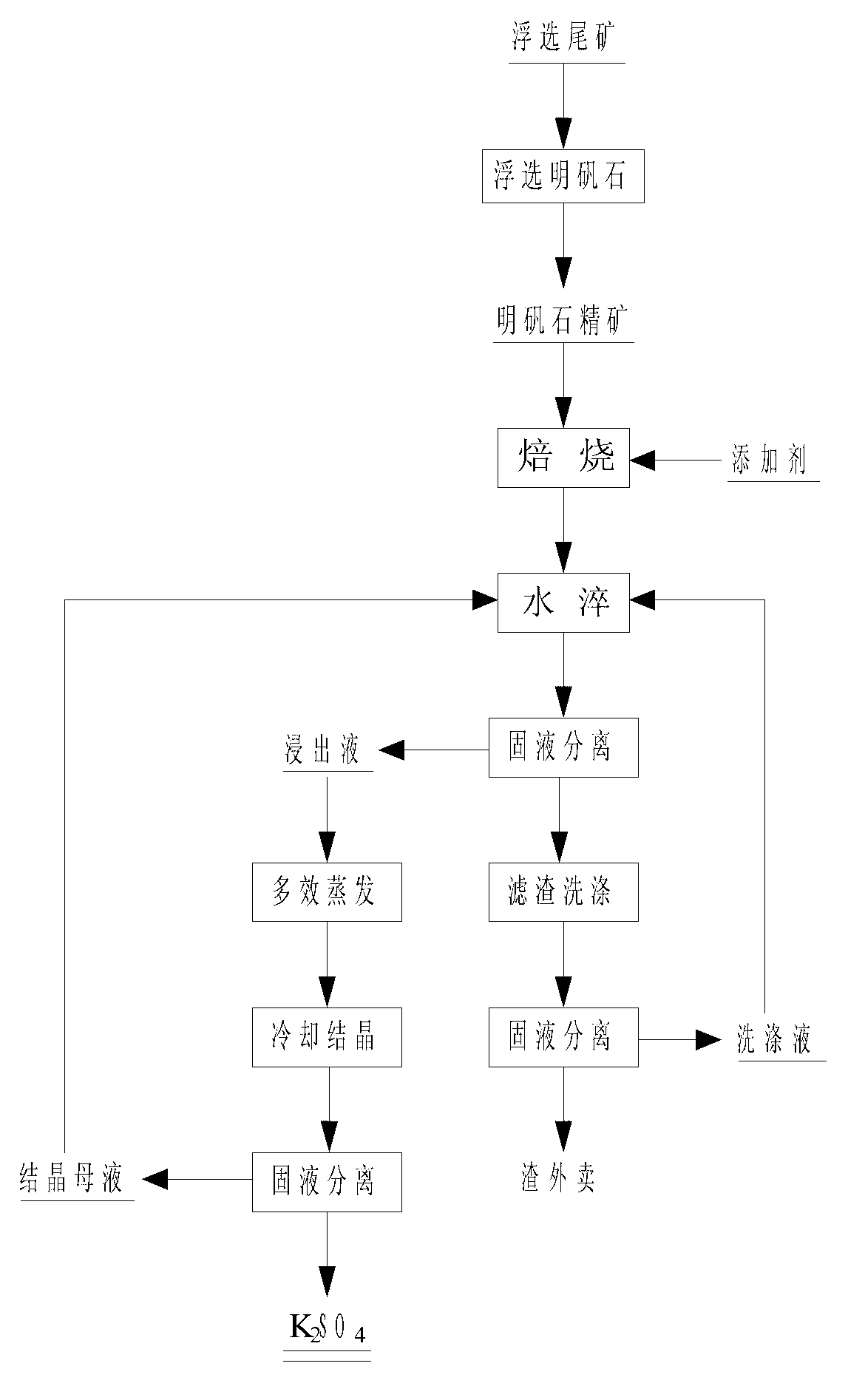

Image

Examples

Embodiment 1

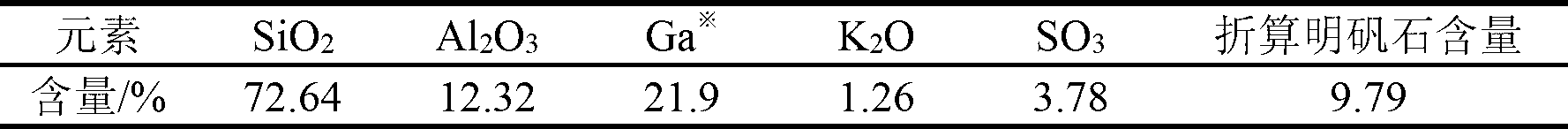

[0020] The main mineral of a flotation tailings is quartz, followed by alunite and dickite, and a small amount exists in the form of sericite, feldspar, chlorite, epidote, etc. The chemical analysis results of the flotation tailings are shown in Table 1.

[0021] Table 1 Analysis results of main elements of a certain flotation tailings / %

[0022]

[0023] Note:" ※ "The unit is g / t, the same below.

[0024] A method for producing potassium sulfate and its by-products from alunite in flotation tailings comprises the following steps in sequence.

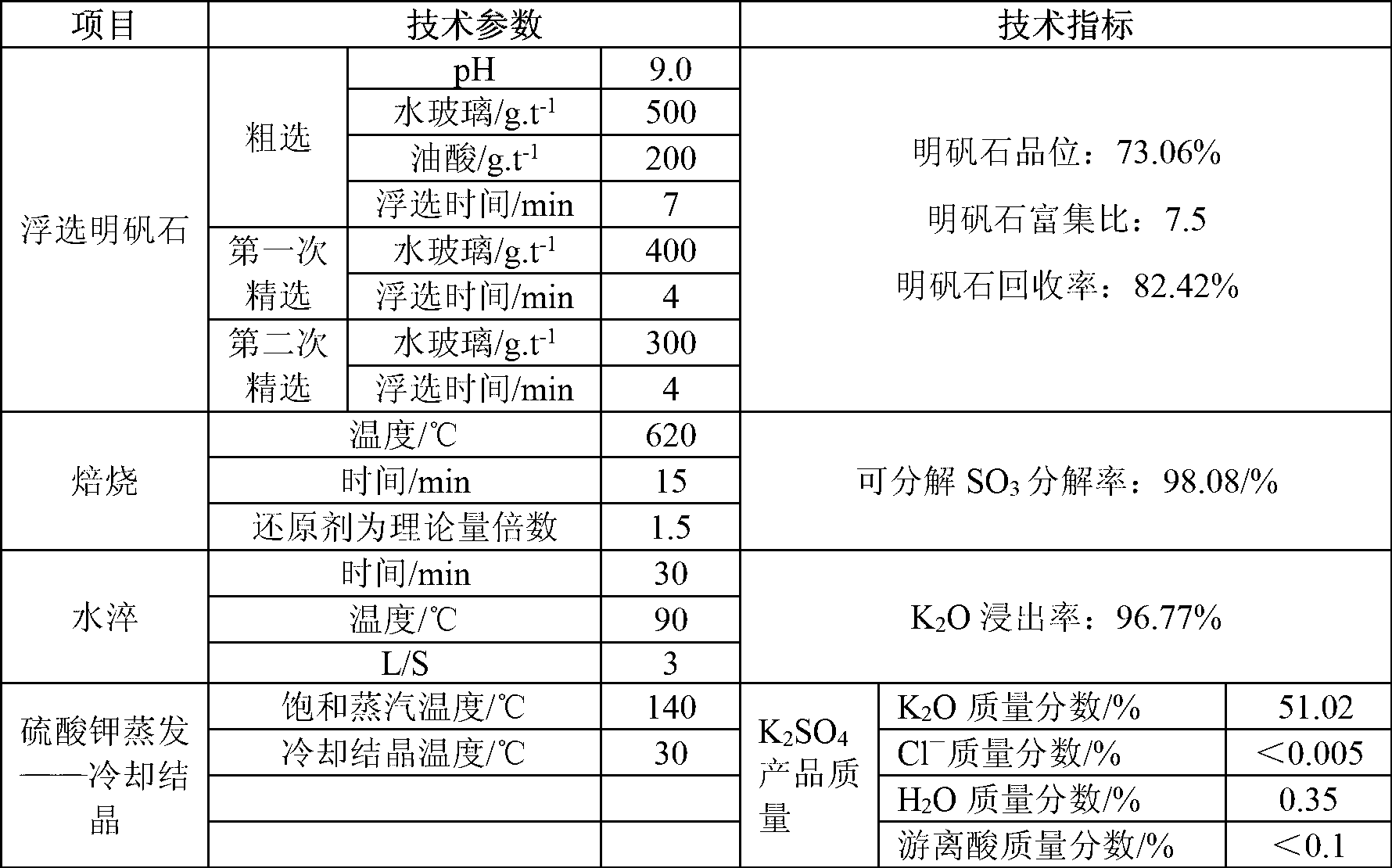

[0025]The first step: alunite flotation: the flotation pulp is adjusted to pH = 9.0 with sodium carbonate, and then the dispersion inhibitor water glass 500g / t is added and stirred for 3 minutes, and the collector oleic acid is stirred for 2 minutes. After 7 minutes of selection, the tailings are discarded; the coarsely selected alunite concentrate is added with water glass 400g / t for the first selection for 4 minutes, and the midd...

Embodiment 2

[0032] The main minerals of a flotation tailings are quartz and chalcedony, followed by alunite, and others include kaolin, sericite, feldspar, etc. The chemical analysis results of the flotation tailings are shown in Table 3.

[0033] Table 3 Analysis results of chemical composition of flotation tailings / %

[0034]

[0035] A method for producing potassium sulfate and its by-products from alunite in flotation tailings comprises the following steps in sequence.

[0036] The first step: alunite flotation: the flotation pulp is adjusted to pH = 9.5 with sodium carbonate, and then the dispersion inhibitor water glass 500g / t is added and stirred for 3 minutes, and the collector oleic acid is stirred for 2 minutes. After 6 minutes of selection, the tailings are discarded; the coarsely selected alunite concentrate is added with water glass 300g / t for the first selection for 4 minutes, and the middle ore selected for the first time is discarded; the first selected alunite concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com