Technology for preparing ceramic tile from high-volume municipal water supply plant sludge

A technology of sludge and high dosage of water supply plant, applied in the production of ceramic materials, clay products, other household appliances, etc., can solve the problems of low strength and low dosage of finished products, save processing costs, improve physical properties, improve The effect of roasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. Raw materials:

[0030] Sludge powder: Dry and crush the dewatered sludge from a water supply plant in Changsha, pass through 28-mesh and 100-mesh sieves into sludge powder, and the particle size of the sludge powder is less than 0.15mm;

[0031] Kaolin: chemically pure

[0032] Potassium feldspar powder: particle size about 0.15mm

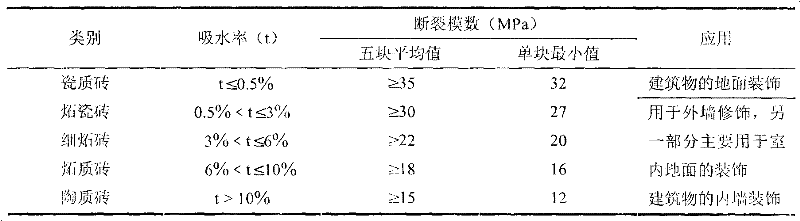

[0033] Table 2 Main components of sludge (w%)

[0034]

[0035] 2. Process steps:

[0036] 1) Ingredients: use sludge powder: kaolin: feldspar powder = 5:5:2 mass ratio ingredients, mix evenly;

[0037] 2) Add water: add 20% water of the total dry weight of the total ingredients to the ingredients, and mix evenly;

[0038] 3) Storage: Store in an electric heating constant temperature drying oven (202-2AB type) (20°C) for 24 hours to make the moisture evenly distributed in the ingredients;

[0039] 4) Compression molding: Put the ingredients into the mold, and use a pressure testing machine (SYA-200B) to press the molding at a pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com