Patents

Literature

79results about How to "Not easy to leach" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkaline residue porcelain granule having package structure and manufacturing method thereof

ActiveCN101759384AIncrease the content of glass phasePrevent dissociationSolid waste managementSufficient timeFree cooling

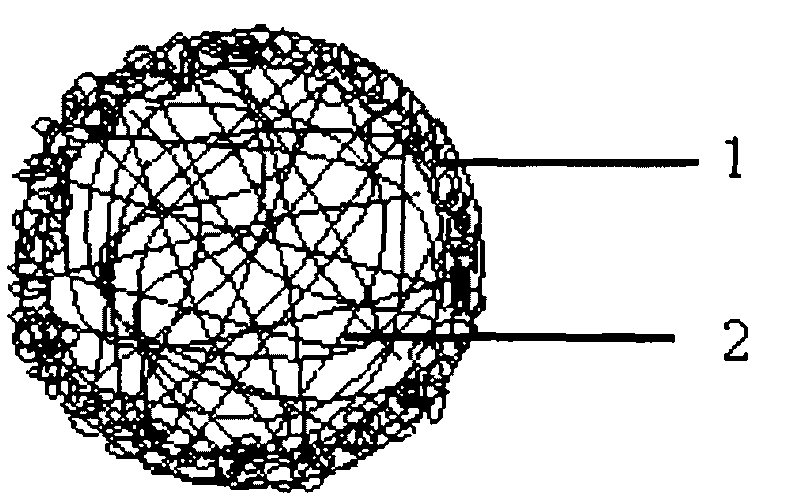

The invention discloses an alkaline residue porcelain granule which has a compound package structure. The alkaline residue porcelain granule comprises a porous core layer (2) and a shell layer having blind holes (1), wherein the porous core layer comprises alkaline residue, glass powder, coal ash and saw dust and the shell layer having blind holes comprises glass powder, clay and saw dust. A method for manufacturing the alkaline residue porcelain granule comprises the steps of: uniformly mixing the materials of the porous core layer and the shell layer having blind holes by a blender, adding water into the dry materials of the porous core layer to pelletize in a pelletizing pan in order to form the pellets of the core layer, placing the pellets into a balling pan which is filled with the dry materials of the shell layer, starting the balling pan, shaking for a sufficient time, packing the materials of the shell on the core layer by rolling in order to form the porcelain granule green-pressing having the package structure, drying the porcelain granule green-pressing at 105 DEG C, pre-burning the dried porcelain granule green-pressing, rising temperature and roasting, and then naturally cooling so as to finish the firing of the alkaline residue porcelain granule. The alkaline residue porcelain granule can efficiently prevent the chloride ion in the alkaline residue from dissociating and improve the application performance of the porcelain granule which uses the alkaline residue as raw materials in the concrete.

Owner:北京元泰达环保科技有限公司

Preparation method of modified collagen fiber adsorbing material

InactiveCN102600805AUnique cavity structureIncrease the number ofOther chemical processesWater contaminantsFiberWastewater

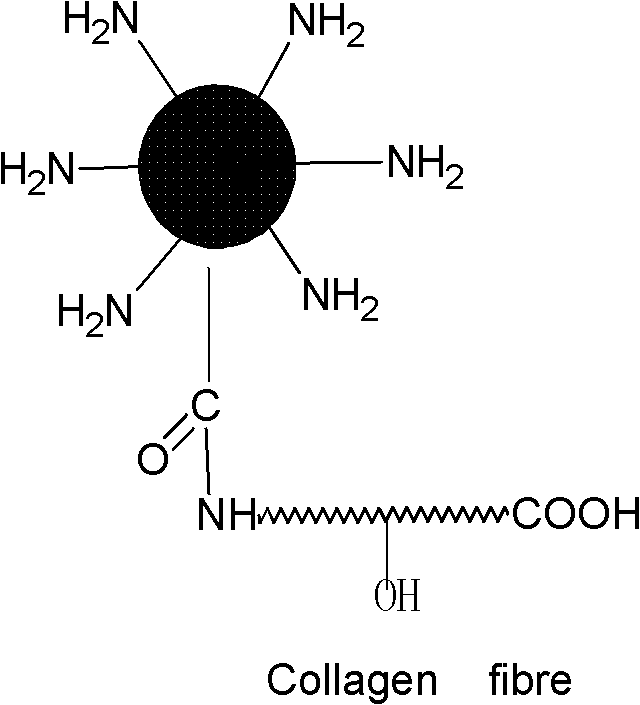

The invention relates to a preparation method of a modified collagen fiber adsorbing material, aiming at solving the problems that the adsorption is not thorough and the usage quantity is large in the prior art. In order to solve the problems in the prior art, the technical scheme of the preparation method is as follows: the adsorbing material is prepared by using collagen fibers as a raw material, and the preparation process sequentially comprises the following steps: step 1, preparing the collagen fibers; step 2, preparing hyperbranched polyamidoamine; and step 3, interlinking hyperbranchedpolyamidoamine on the collagen fibers, carrying out amino derivatization modification on the callogen fibers so as to prepare the modified collagen fiber adsorbing material. The adsorbing material can be used for treating wastewater containing Cr(III) in leather, metallurgy, electroplating and other industries, is non-toxic, environment-friendly and biodegradable, has no potential safety hazards and is low in cost.

Owner:SHAANXI UNIV OF SCI & TECH

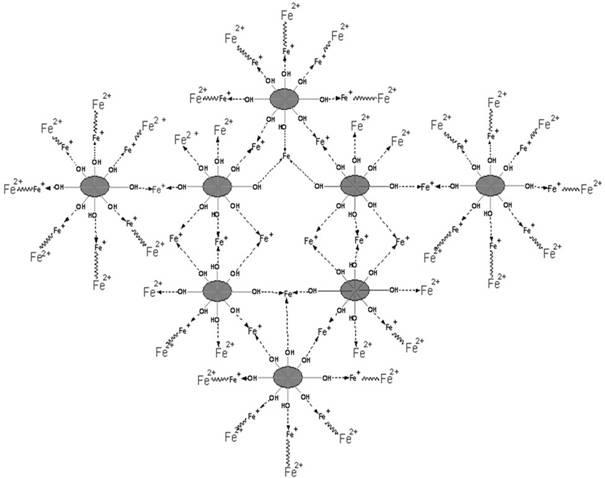

Hyperbranched polymer flocculant for treating waste drilling fluid and preparation method thereof

InactiveCN102030399AGood flocculation effectNo secondary pollutionWater/sewage treatment by flocculation/precipitationFlocculationSynthesis methods

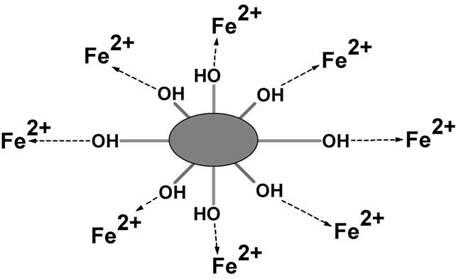

The invention relates to the technical field of water treatment, in particular to an efficient hyperbranched polymer flocculant for treating waste drilling fluid generated during an oil and gas drilling process and a preparation method thereof, which is used for solving the problems such as pollution and unstable treatment effect in the prior art. For the special system of the waste drilling fluid, the invention provides the efficient hyperbranched polymer flocculant which has the advantages of environmental friendliness, high flocculation efficacy and stable effect. The hyperbranched polymerflocculant is prepared by synthesizing an AB2-type monomer to obtain a hydroxyl-terminated hyperbranched polymer, and then loading metal ions on the polymer. The obtained hyperbranched polymer flocculant provided by the invention has the advantages of high flocculation efficacy and no secondary environmental pollution; and the synthesis method and operation are simple, and industrial production can be realized easily.

Owner:SHAANXI UNIV OF SCI & TECH

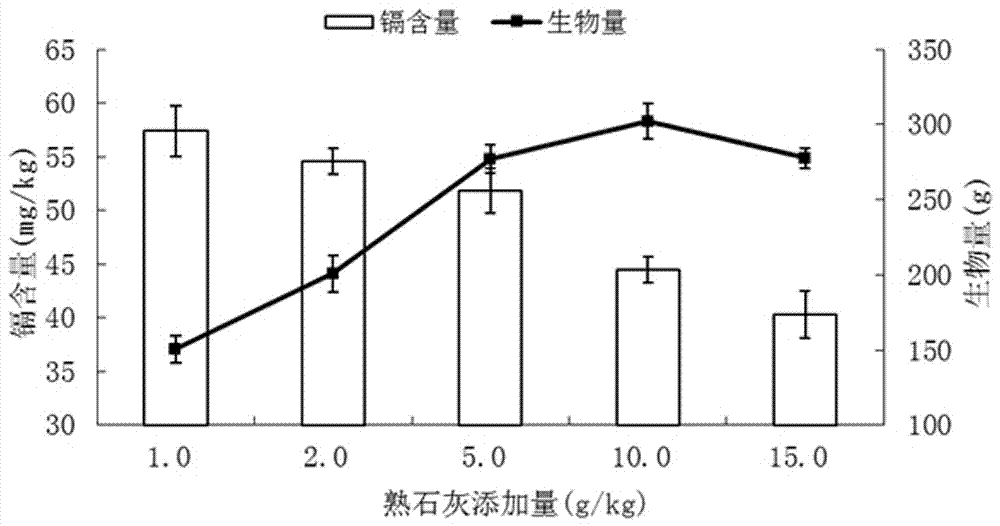

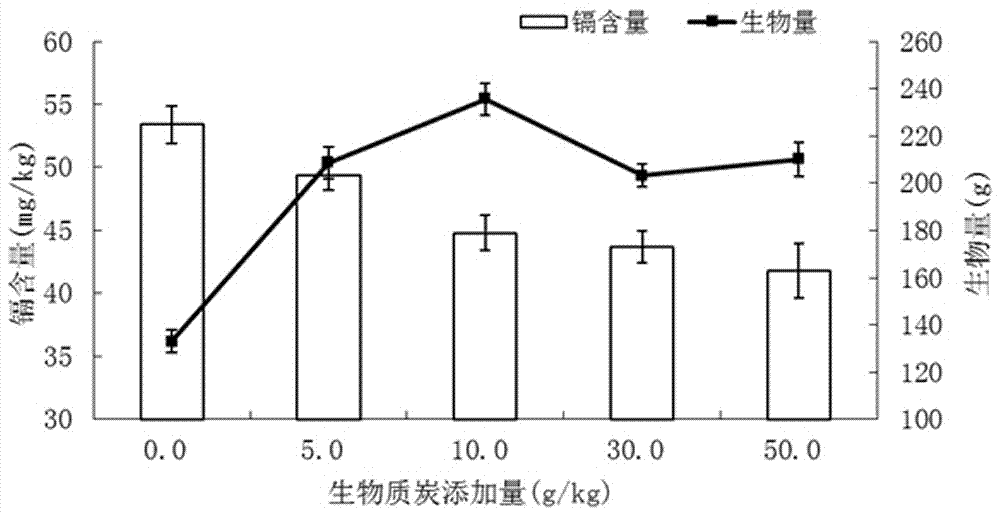

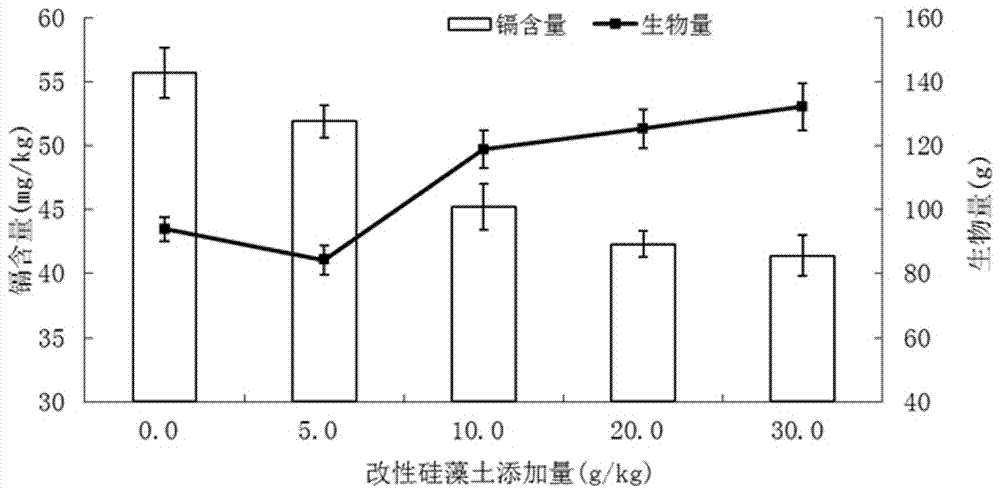

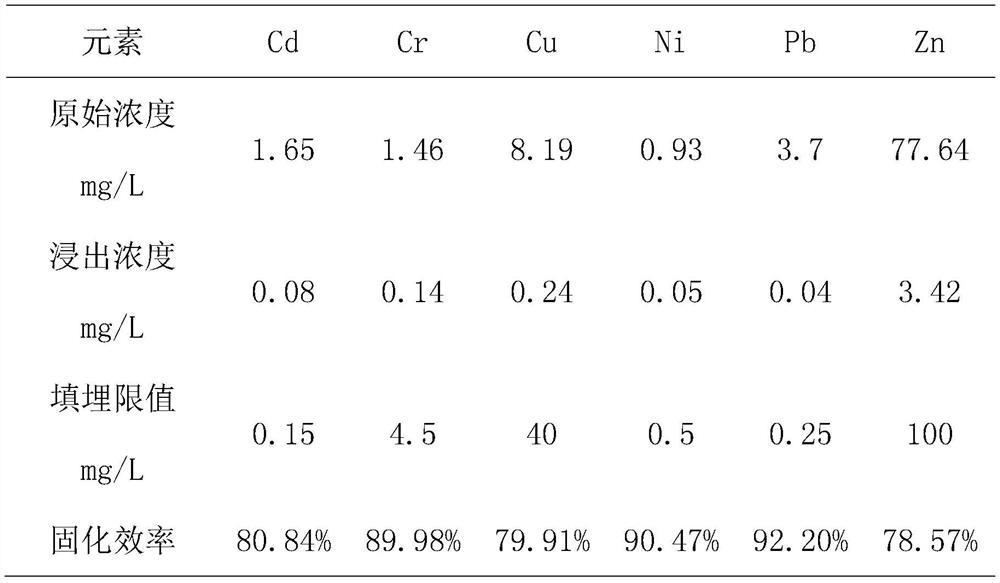

Compound passivator of heavy metal contaminated soil and preparation method and application of compound passivator

ActiveCN107987835ARaise the pHNot easy to leachOther chemical processesContaminated soil reclamationBiomass carbonPesticide residue

The invention relates to a compound passivator of heavy metal contaminated soil and a preparation method and application of the compound passivator of heavy metal contaminated soil. The compound passivator comprises 8.0 to 10.0% of slaked lime, 25.0 to 30.0% of modified diatomite, 35.0 to 40.0% of modified phosphogypsum and 25 to 30.0% of biomass carbon in percentage by weight. The use amount of the compound passivator varies according to the soil contamination degree, generally within 1.5% to 2.0%. The preparation of the compound passivator is prepared by mixing the slaked lime, the modifieddiatomite, the modified phosphogypsum and biomass carbon proportionally; the compound passivator disclosed by the invention has a good application effect in remediation of cadmium, lead, zinc and copper compound contaminated soil by a synergistic action of multiple different passivation mechanism components, further can improve the vegetable quality and reduce crop absorption of pesticide residues, and is suitable for remediation of the large-area heavy metal contaminated soil, including the remediation of heavy metal contaminated farmland soil near industrial and mining areas and contaminatedsites in heavy metal production enterprises. The compound passivator can passivate various heavy metal elements and has high passivation efficiency.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

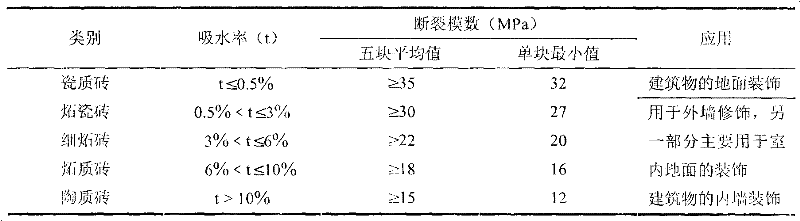

Technology for preparing ceramic tile from high-volume municipal water supply plant sludge

InactiveCN102173749AEfficient curingEasy to leachCeramic materials productionClaywaresBrickDry weight

The invention discloses a technology for preparing a ceramic tile from high-volume municipal water supply plant sludge, and belongs to the field of solid waste recycling and building material production in environmental engineering. The technology comprises the following steps of: uniformly mixing 38 to 42 mass percent of municipal water supply plant dewatering sludge powder (dry weight) with a certain grain size, 38 to 42 mass percent of kaolin and 16 to 24 mass percent of potassium feldspar powder, adding water which is about 20 percent based on the dry weight of the total material, uniformly mixing, and storing for certain time in a constant-temperature environment; and performing compression molding under certain pressure, raising the temperature from room temperature to 1,200 DEG C by a certain method and keeping temperature for one hour, and naturally cooling to the room temperature to obtain the finished product. Through detection, the main technical indexes meet the related national standard. By the technology, the water supply plant sludge is effectively utilized, and other brick production raw materials are substituted; and the technology has good environmental benefit and certain economic benefit.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Maca wine and preparation method thereof

ActiveCN105199927AGuaranteed efficacyKeep the aromaDigestive systemAlcoholic beverage preparationFlavorAfter treatment

The invention discloses a maca wine and a preparation method thereof. The maca wine is prepared from the following raw materials in part by weight: 900-1000 parts of base liquor, 10-30 parts of maca, 1-2 parts of cultivated ginseng, 6-8 parts of the fruit of Chinese wolfberry, 1-5 parts of longan, 2-10 parts of jujubes, 2-8 parts of raspberry, 1-5 parts of sealwort extracts, 1-5 parts of extracts from pueraria and 0.5-3 parts of cordyceps militaris extracts. The preparation method comprises the following steps of pretreatment, extraction, mixing and after-treatment. The maca wine does not have traditional drug flavor, tastes good, and has effects of nourishing yin, reinforcing qi, refreshing and boosting immunity; and after drinking the maca wine, a person does not have a headache.

Owner:CHUXIONG BAICAOLING PHARMA DEV

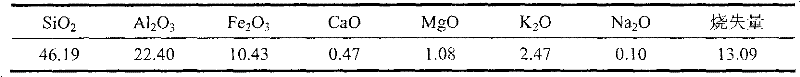

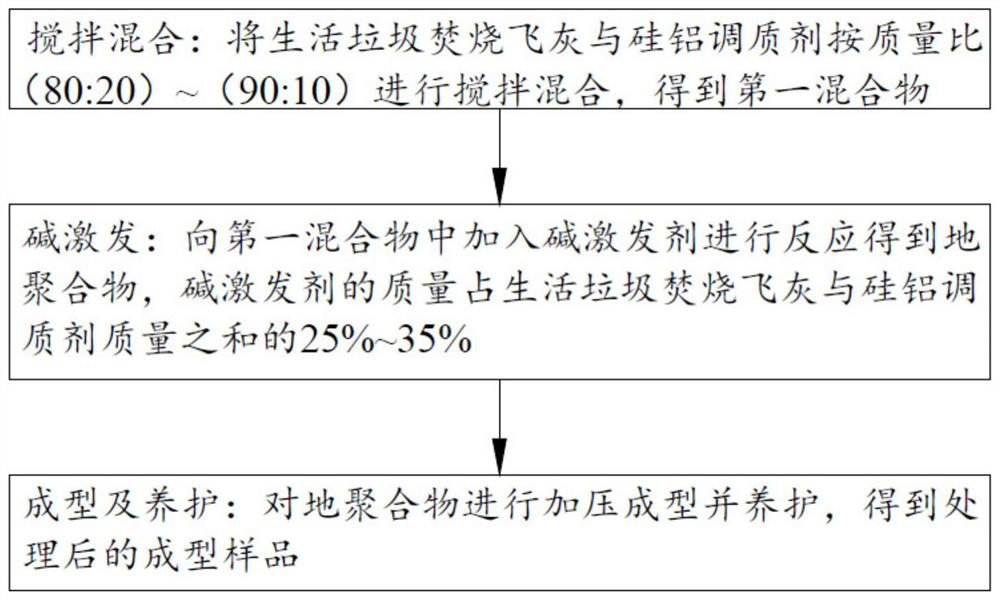

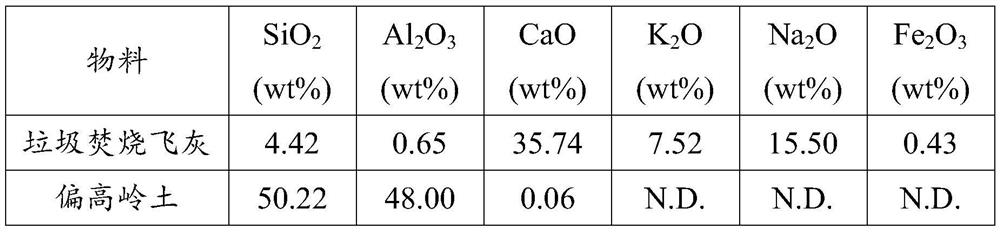

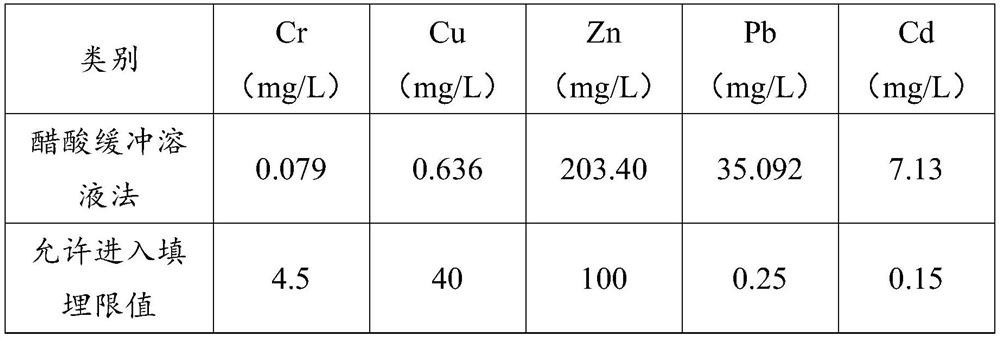

Treatment method of household garbage incineration fly ash

InactiveCN113072314AImprove curing effectGuaranteed capacity reductionSolid waste managementCement productionGeopolymerEnvironmental engineering

The invention relates to the field of waste resource utilization and environmental protection, and in particular relates to a treatment method of household garbage incineration fly ash. The treatment method comprises the steps of stirring and mixing, alkali excitation, forming and curing. The method specifically comprises the steps of stirring and mixing the household garbage incineration fly ash and a silicon-aluminum tempering agent according to a mass ratio of (80: 20) to (90: 10) to obtain a first mixture; then adding an alkali activator into the first mixture for reaction to obtain a geopolymer, wherein the mass of the alkali activator accounts for 25 to 35% of the sum of the mass of the household garbage incineration fly ash and the mass of the silicon-aluminum tempering agent; and finally, carrying out pressure forming and maintenance on the geopolymer to obtain a treated formed sample. According to the treatment method, volume reduction of the treated household garbage incineration fly ash is guaranteed, meanwhile, the heavy metal solidification effect is good, and the potential danger of heavy metal leaching is avoided.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

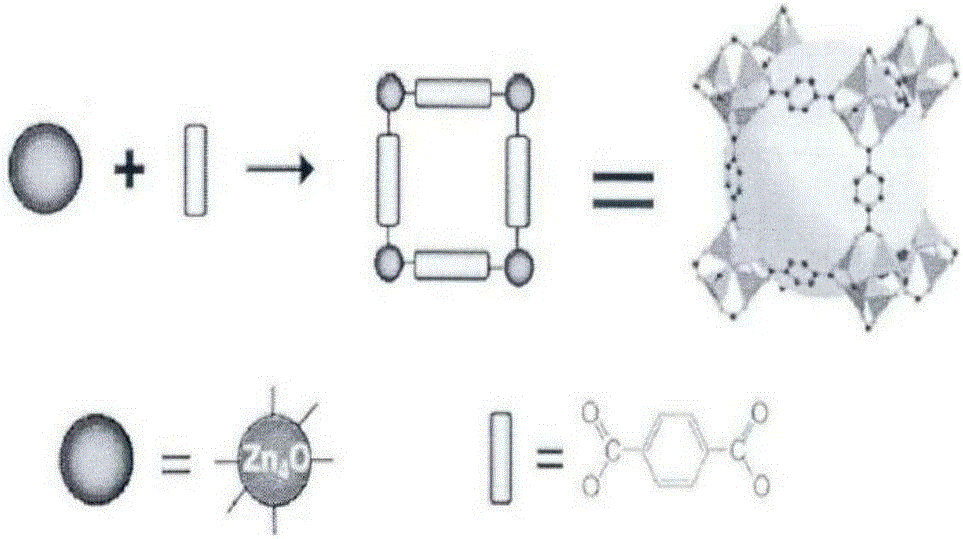

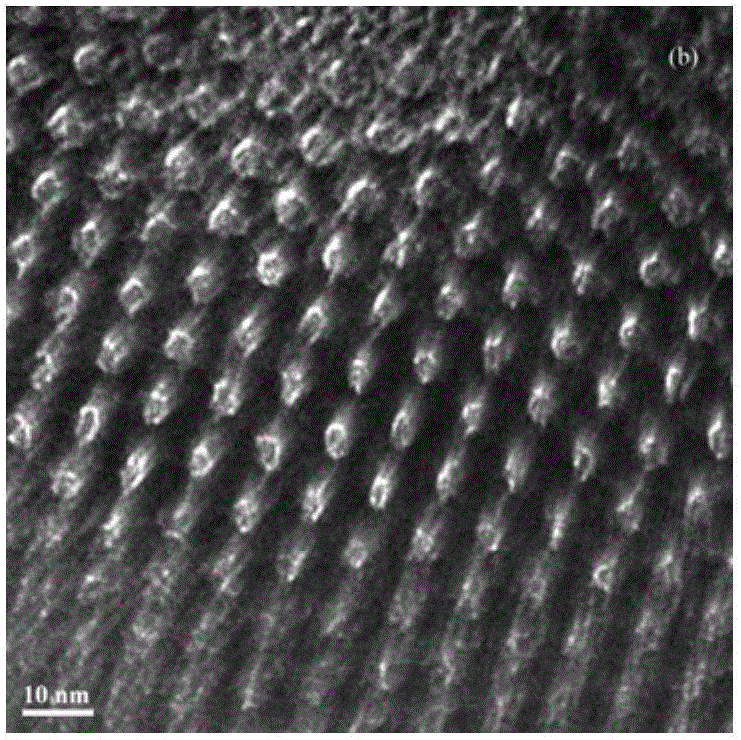

Preparation method for MOFs heavy metal collecting agent

ActiveCN106268652AReduce dosageImprove the capture effectOther chemical processesWater/sewage treatment by sorptionDimethyl formamideHeavy metals

The invention discloses a preparation method for a MOFs heavy metal collecting agent. The method comprises the following steps: taking dimethyl formamide as a deprotonation alkaline solvent, macromolecule metal salt containing sulfydryl structure as a dopant and zinc nitrate and mesitylenecarboxylic acid as precursors, and then compounding by adopting a solvothermal method. The zinc-based MOFs prepared according to the method has a single mesoporous and micropore crystal structure; the mass transfer resistance is overcome in the reaction process; the mass transfer efficiency is improved; the prepared heavy metal collecting agent is a solid adsorbent and is easy to collect and regenerate; the leaching toxicity is low; the adsorption efficiency is high; the reutilization is realized.

Owner:张少强

Tech, for sintering pottery floor tile by urban sewage mud

InactiveCN1793016AImprove wear resistanceNot corrosiveCeramic shaping apparatusSludgeRoom temperature

The invention relates to a technology that could fire city sewage sludge into ceramic floor tile. The process including the following steps: mixing 13%-15% city sewage sludge powder, 55%-60% kaolin, 26-30% feldspar powder equally, adding 10-12% water, storing for 14-16 in constant temperature of 18-22 degree centigrade, pressing and molding under 90MPa, heating to 400 degree centigrade at the speed of 50 degree centigrade per ten minutes, when reaching 100 degree centigrade, keeping for 1 hour, heating to 700 degree centigrade by the speed of 50 degree centigrade per ten minutes from 400 degree centigrade, and heating to 1200 degree centigrade by the speed of 70 degree centigrade per ten minutes from 700 degree centigrade, keeping for 2 hours; naturally cooling to room temperature to gain finished product. The invention has great environment benefit and economic benefit.

Owner:HUNAN UNIV

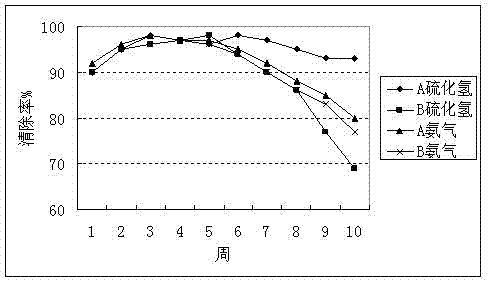

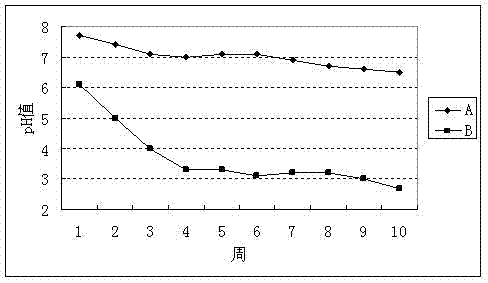

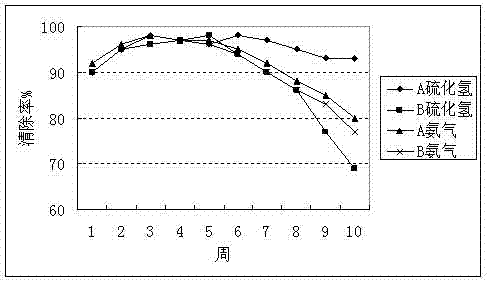

Deodorization composite biological stuffing as well as preparation method and application of the same

InactiveCN102389708AWithstand loadImprove breathabilityDispersed particle separationDeodrantsDiammonium phosphateCarvacryl acetate

The invention discloses a deodorization composite biological stuffing as well as a preparation method and application of the same. The deodorization composite biological stuffing comprises a stuffing main body and an adhesion agent, wherein the adhesion agent takes account for 10-40% of the stuffing main body in usage amount by weight percentage; in percent by weight, the stuffing main body comprises 70-80% of calcium carbonate, 5-10% of diammonium phosphate, 10-20% of bark powder, 0-5% of urea and 0-5% of the soybean meal; and in percent by weight, the adhesion agent comprises one or more of 30-100% of ethylene / vinyl acetate, and 20-70% of Na2O nSiO2 / K2O nSiO. By the steps of mixing, extrusion forming, drying and the like, the stuffing main body and the adhesion agent are prepared to the deodorization composite biological stuffing. The stuffing is matched with deodorization microorganism for use, second fermentation liquor obtained from the deodorization microorganism which is subject to seed cultivation and fermenter cultivation is uniformly scattered on the stuffing, and after growing, the microorganism can be used for deodorization work. The deodorization composite biological stuffing has the advantages of being excellent in deodorization effect and long in using time which is improved by 30% compared with that of the way using bark as stuffing.

Owner:SHANGHAI MASTECK ENVIRONMENTAL

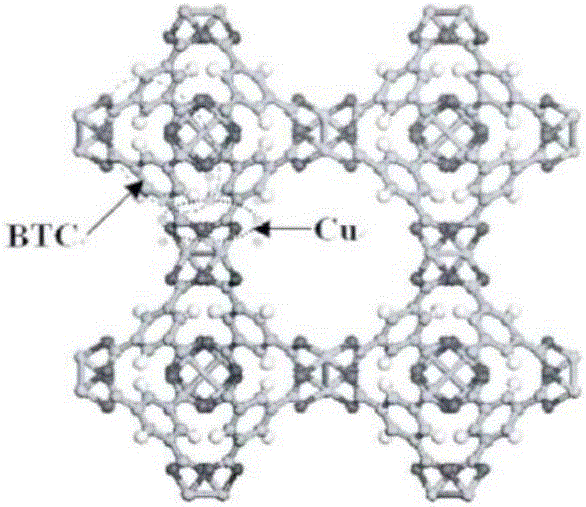

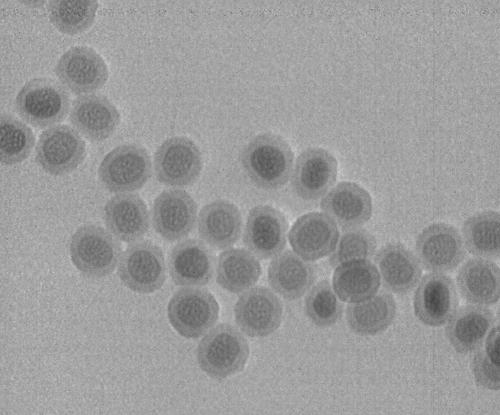

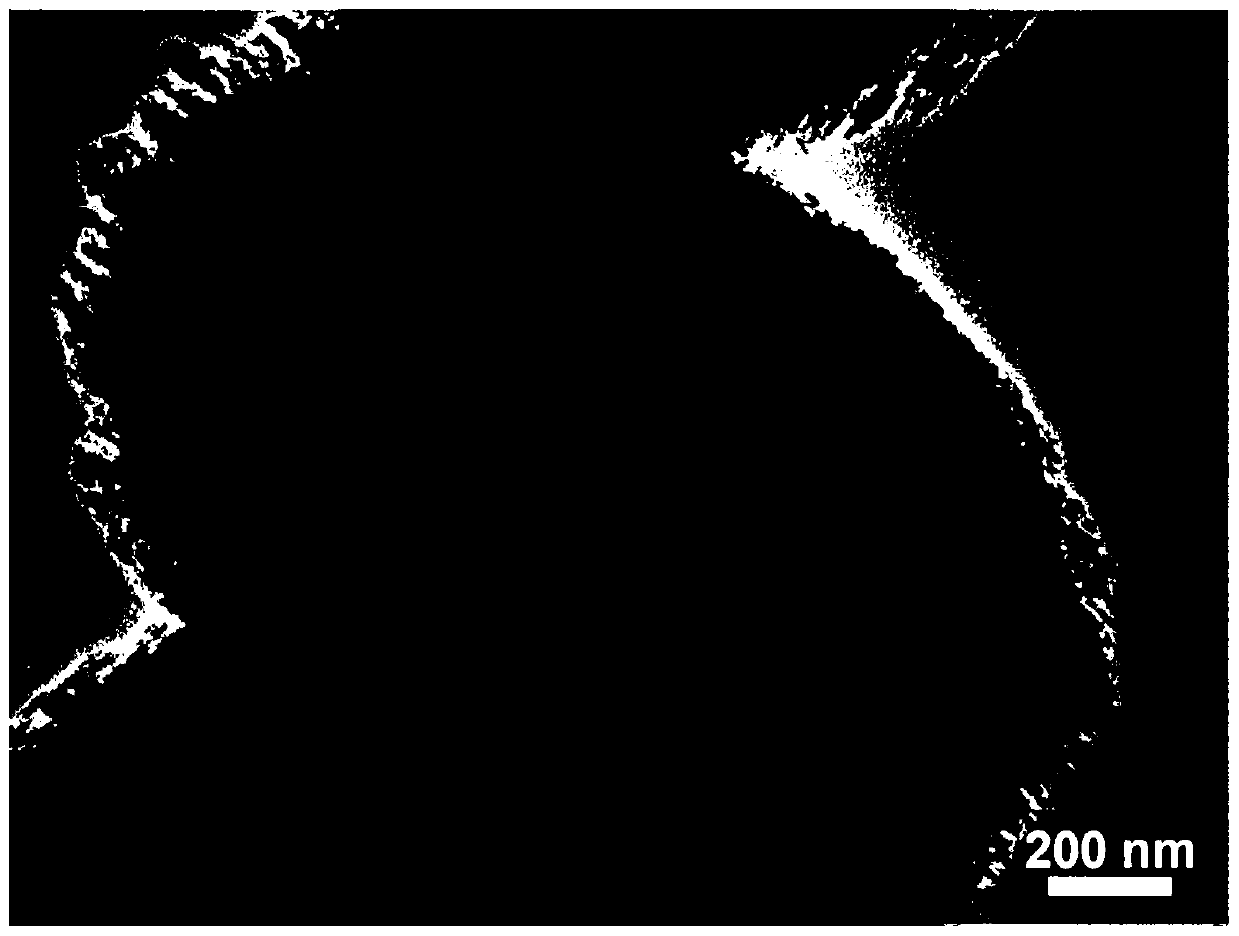

Horseradish peroxidase @ MOF composite catalyst and preparation method thereof

ActiveCN110592064ASubstantial advantagesEasy to prepareOxidoreductasesOn/in inorganic carrierIonChemistry

The present invention discloses a horseradish peroxidase @ MOF composite catalyst and a preparation method thereof. The preparation method comprises the following steps: dissolving dimethyl sulfoxidein deionized water to obtain a dimethyl sulfoxide aqueous solution, dissolving horseradish peroxidase in deionized water to obtain a horseradish peroxidase aqueous solution, adding phthalic anhydridein the dimethyl sulfoxide aqueous solution to obtain a mixed solution, adding the mixed solution into the horseradish peroxidase aqueous solution after ultrasonic uniform mixing, conducting stirring at 0-4 DEG C for 1-3 h, and centrifuging and washing the product to obtain a modified horseradish peroxidase; dispersing MOF shell materials into deionized water to obtain a dispersion liquid of the MOF shell materials, then adding the obtained modified horseradish peroxidase into the dispersion liquid of the MOF shell materials, and conducting stirring for reaction to obtain the horseradish peroxidase @ MOF composite catalyst. The horseradish peroxidase @ MOF composite catalyst can be applied to catalytic conversion of o-phenylenediamine.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of freeze-dried instant powder containing dried tubers of dendrobium devonianum or dendrobium officinale kimura

InactiveCN106072516AEasy to leachImprove qualityFood shapingNatural extract food ingredientsMedicineFreeze-drying

The invention discloses a preparation method of freeze-dried instant powder containing dried tubers of dendrobium devonianum or dendrobium officinale kimura. The preparation method comprises the following technological processes of pretreating raw materials namely fresh tubers of the dendrobium devonianum or the dendrobium officinale kimura, performing freezing, performing freeze drying, performing crushing, performing blending, performing mixing, performing pelletization, performing subpackaging, performing packaging, obtaining finished products and the like. The processed freeze-dried products are good in rehydration performance, high in dissolving speed, convenient to carry and drink, and long in quality guarantee period, and have a broad market prospect.

Owner:李莉萍

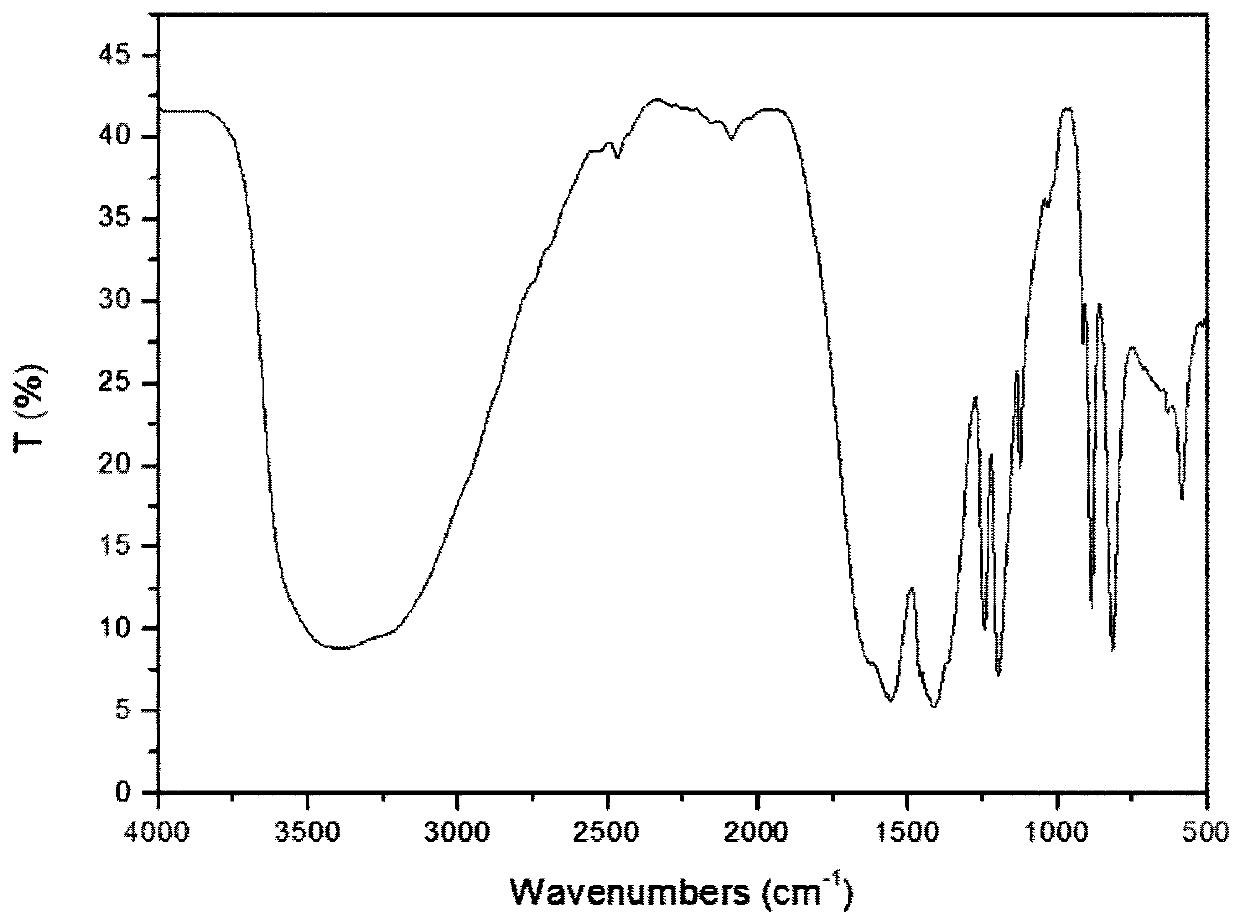

High-strength high-toughness self-repairing fluorescent double-network hydrogel and preparation method thereof

The invention discloses high-strengthhigh-toughness self-repairing fluorescent double-network hydrogel and a preparation method thereof. The preparation method comprises the following steps: adding double-bond modified rare earth doped NaREF4 fluorescent nanoparticles into a solution system consisting of agar, a monomer and an initiator, and carrying out photo-initiation polymerization to generatephysical crosslinking and chemical crosslinking, thereby obtaining the high-strengthhigh-toughness self-repairing fluorescent double-network hydrogel. By adding the double-bond modified rare earth doped NaREF4 fluorescent nanoparticles, the hydrogel is endowed with adjustable and concealed fluorescence characteristics, the surface modified double bonds can be crosslinked with a hydrogel monomer to serve as a nano crosslinking agent, the crosslinking degree of a hydrogel network is increased, and the mechanical property of the hydrogel network is improved. The high-strengthhigh-toughness self-repairing fluorescent double-network hydrogel prepared by the invention not only has high mechanical strength, high toughness, fatigue resistance and self-healing performance, but also has adjustableand concealed fluorescence performance, and has good application prospects in the fields of biological detection, sensing, intelligent packaging and the like.

Owner:HUNAN UNIV OF TECH

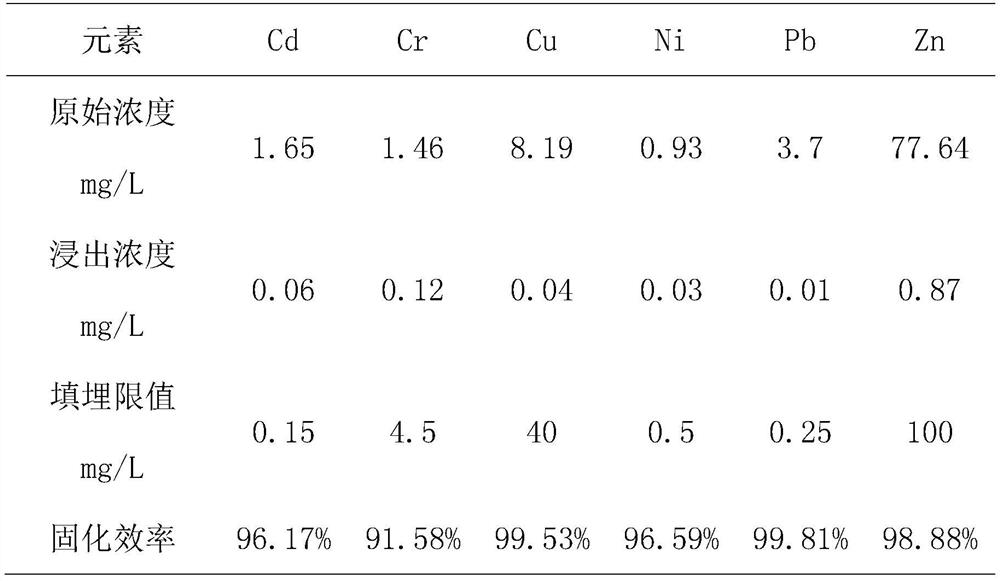

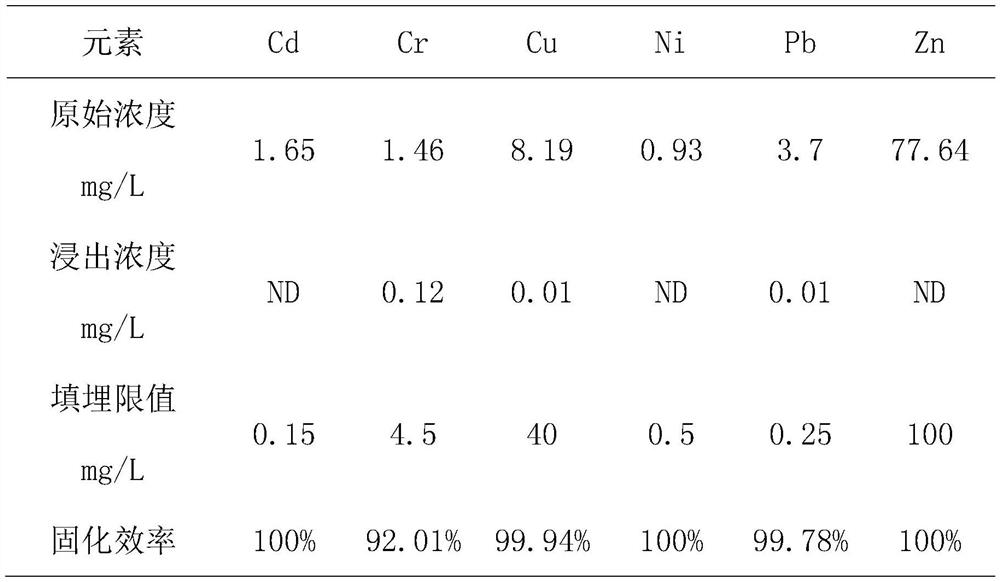

Method for stabilizing heavy metals in waste incineration fly ash through combination of coal gangue and calcium oxide

ActiveCN113441526ASave stacking costLow raw material costSolid waste disposalCement productionCalcium silicateIon exchange

The invention discloses a method for stabilizing heavy metals in waste incineration fly ash through combination of coal gangue and calcium oxide, and belongs to the field of household waste incineration fly ash treatment. Coal gangue and amorphous SiO2 and Al2O3 in household waste incineration fly ash are subjected to a geological polymerization reaction under the condition of an alkali activator, an inorganic polymer of a three-dimensional net structure is formed, meanwhile, calcium oxide is added, a large quantity of hydrated calcium silicate, hydrated calcium aluminosilicate and hydrated sodium aluminosilicate gel are formed in a cured body during maintenance and react with the heavy metals in manners of physical encapsulation, physical adsorption and ion exchange, so that the heavy metals in the fly ash are harmlessly treated, and it is guaranteed that the heavy metal leaching concentration of the fly ash-coal gangue-calcium oxide polymerization cured body meets the landfill safety standard. The heavy metals in the waste incineration fly ash are stabilized and produced though combination of coal gangue and calcium oxide, the curing efficiency of the heavy metals in the fly ash is further improved, the curing cost is reduced, and the environment-friendly concept of treating wastes with wastes is met.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD +1

Hygroscopic antibacterial hydrocolloid dressing and preparation method thereof

InactiveCN106729961AImprove mechanical propertiesGood flexibilityBandagesBiopolymerAntibacterial property

The invention belongs to the field of medical biopolymer materials and particularly relates to a hygroscopic antibacterial hydrocolloid dressing and a preparation method thereof. The preparation method comprises the steps of burdening, extruding, secondary extrusion, injection molding and ageing molding in sequence to prepare a hygroscopic antibacterial hydrocolloid dressing product. The preparation technology is simple and easy to process and massive production is easy to implement; the prepared hygroscopic antibacterial hydrocolloid dressing is capable of absorbing a lot of seepage and creating a humid microenvironment for wound healing; meanwhile, the contained sodium alginate and quaternized carboxymethyl chitosan are fully mixed and then form more hydrogen bonds, so that the gelatinization reaction is strengthened, the hydrocolloid dressing is capable of keeping relatively good integrity after absorbing a lot of wound seepage, is not sticky to a wound and has certain elasticity, antibacterial property and autohension; the comfort level of a patient is improved; and healing of the wound is accelerated.

Owner:GUANGDONG TAIBAO MEDICAL DEVICE TECH RES INST CO LTD

Composite remediation agent for heavy metal contaminated soil and application method

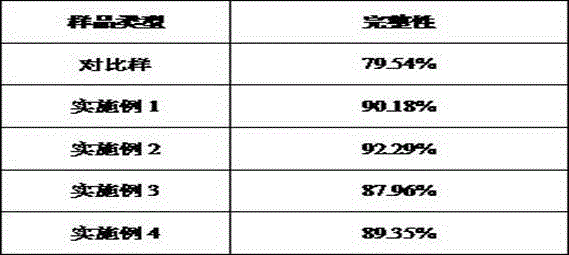

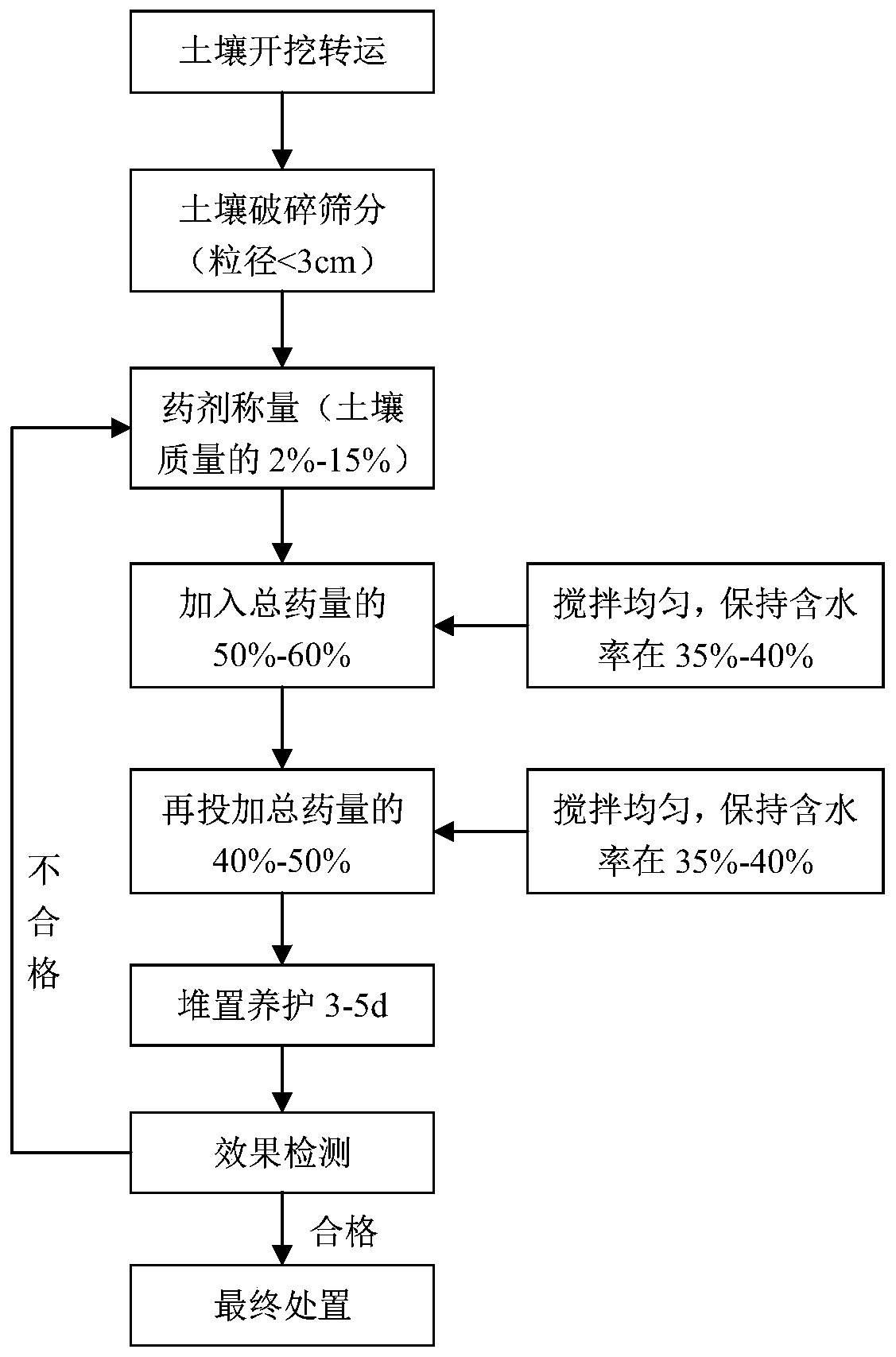

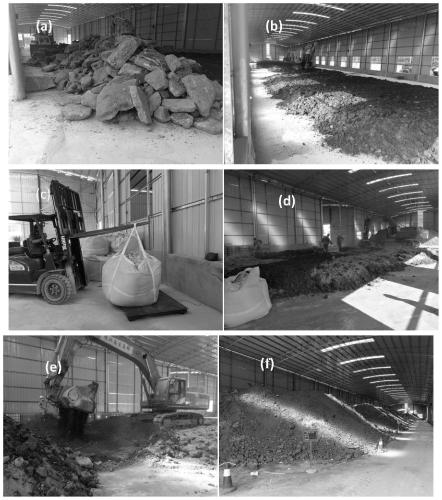

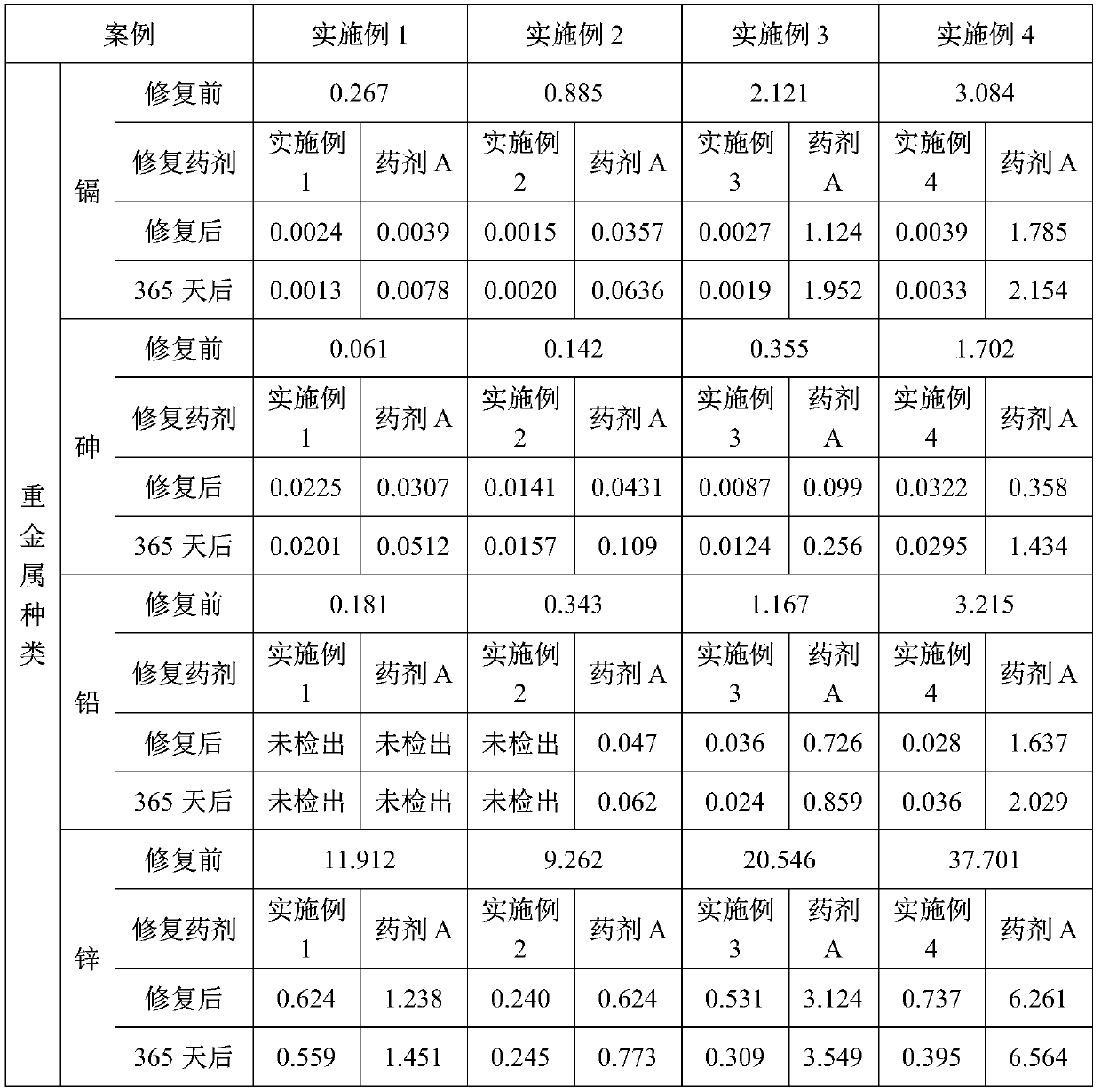

ActiveCN111575011AChange in redox potentialChanging the valence state of heavy metalsContaminated soil reclamationOrganic fertilisersSoil scienceSoil heavy metals

The invention discloses a composite remediation agent for heavy metal contaminated soil and an application method, and belongs to the field of remediation of heavy metal contaminated soil. The composite remediation agent is prepared from, by mass, 25-40 parts of an iron-based agent, 5-15 parts of a sulfur-based agent, 40-60 parts of a calcium-based agent and 5-10 parts of organic matters, whereinthe organic matters are fulvic acid and at least one of ulmic acid and humic acid. The agent provided by the invention can adjust the dosage and component proportion of each agent according to the content of heavy metals in soil, and is widely applied to different types of polluted soil. The composite remediation agent has a good remediation effect on cadmium, lead, zinc, arsenic and other heavy metal composite contaminated soil, and has the advantages of long-term stability, short remediation time, flexible agent proportioning, low consumption and treatment cost saving.

Owner:CHANGSHA SCI ENVIRONMENTAL TECH

Deodorization composite biological stuffing

InactiveCN104056544AHigh strengthHigh bonding strengthDispersed particle separationAir quality improvementDecompositionAdditive ingredient

The invention provides deodorization composite biological stuffing. The deodorization composite biological stuffing comprises the following components in percentage by weight: 15%-25% of bark powder, 5%-15% of saw dust, 40%-50% of calcium carbonate, 1%-5% of bamboo charcoal powder and 10%-40% of a bonding agent, wherein the bonding agent is a mixture of ethylene / vinyl acetate and Na2O.nSiO2. The stuffing has high intensity, can keep favorable bonding strength in a damp environment for a long time, and plays a role of fixing and releasing nutritional substances; the nutritional ingredients are released slowly by virtue of a dissolving diffusion and microorganism decomposition synergistic effect and are difficult to leach at the state with water, thus the stuffing is superior to traditional organic stuffing.

Owner:应丽红

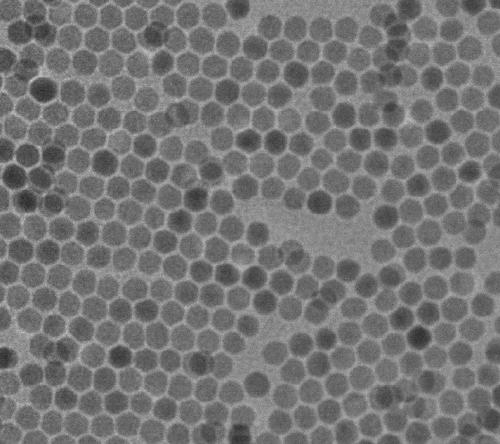

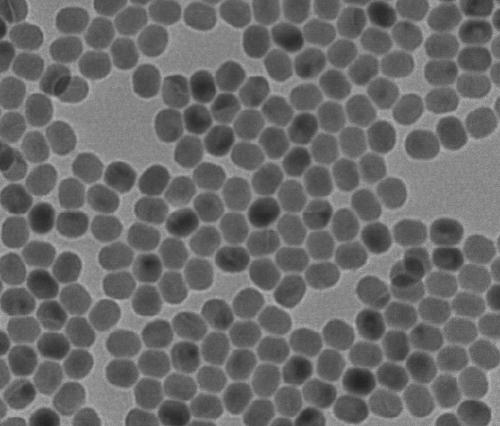

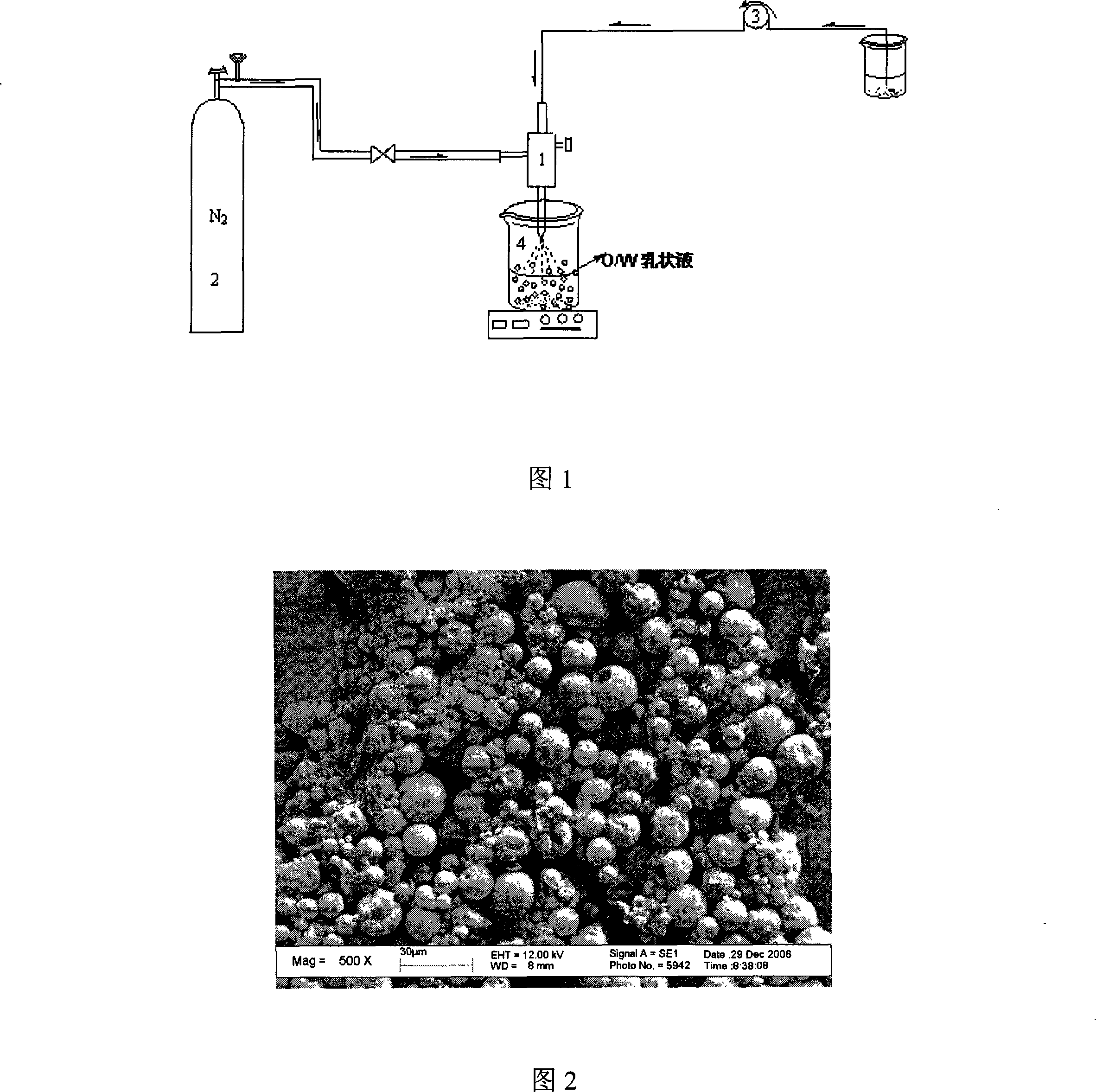

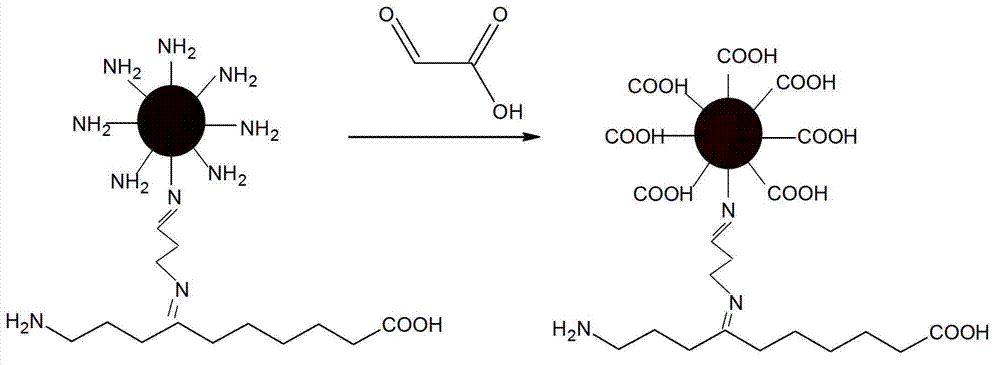

Method for fixing metal oxide by using polyurea microcapsule

InactiveCN101234321AImmobilizationHigh activityCatalyst activation/preparationMicroballoon preparationPeristaltic pumpSprayer

The invention discloses a method for fixing metal oxide by using polyurea microcapsules, the steps of the method are provided as follows: forming solution A by adding 1 to 10 weight parts of surfactant I into 10 to 50 volume parts of deionized water; forming suspension B by ultrasonically dispersing for 20 to 30 minutes after adding 1 to 10 weight parts of diisocyanate, 0.1 to 1 weight parts of metal oxide and 1 to 10 weight parts of surfactant II into 5 to 30 volume parts of organic solvent; pumping the suspension B into a sprayer with a peristaltic pump by taking N2 as the carrier gas, and forming stable O / W emulsion liquid by spraying the solution A after the atomization and simultaneously fast interfacial polymerization happens; obtaining solid powders through vacuum concentration; washing the solid powders in ethanol and acetone, thus obtaining the polyurea microcapsules of the fixed metal oxide after natural drying. The method of the invention has the advantages of simple process, easy operation, low cost, low damage rate and the controllable particle size of the microcapsules of 2 to 60 Mum, etc.

Owner:SOUTH CHINA UNIV OF TECH

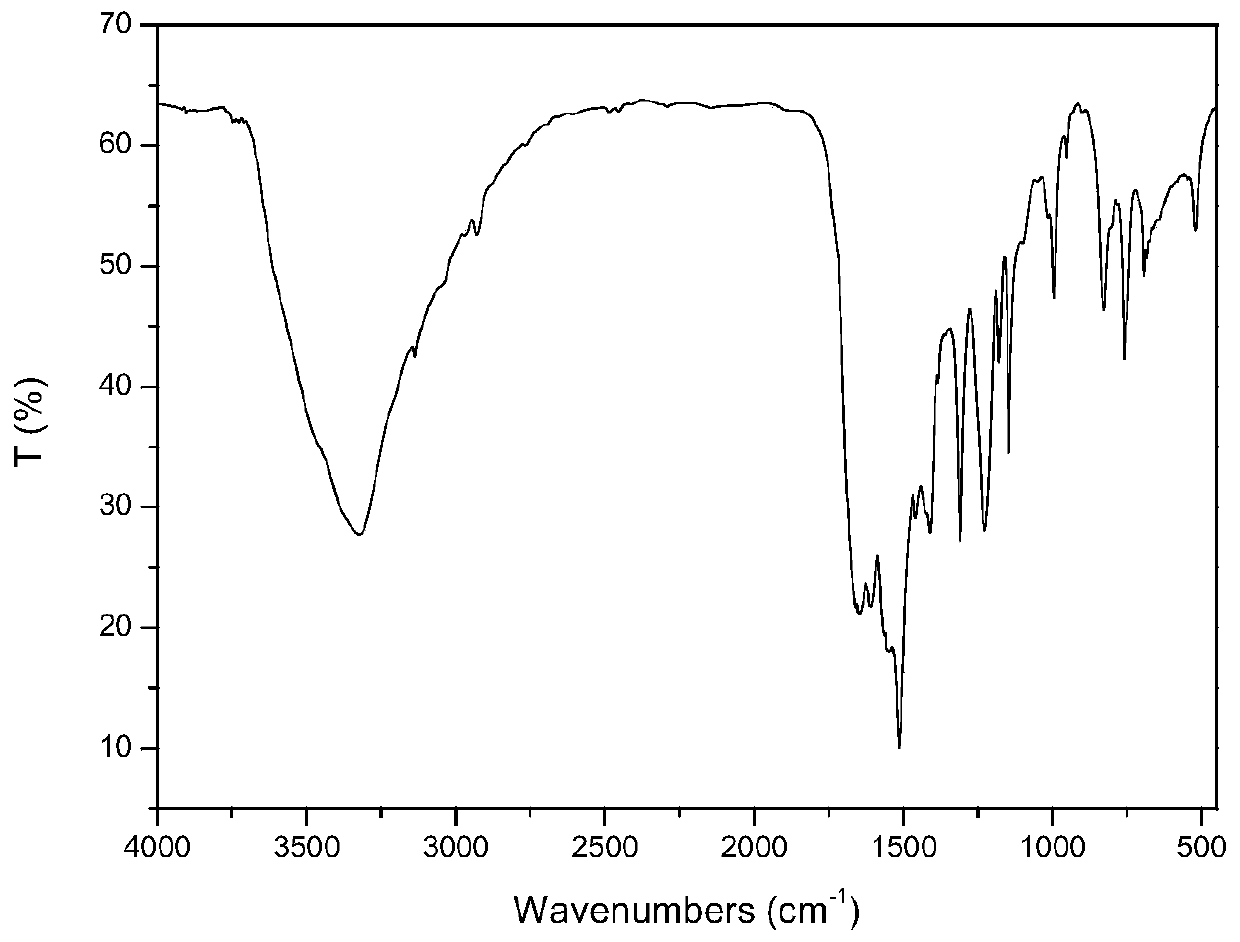

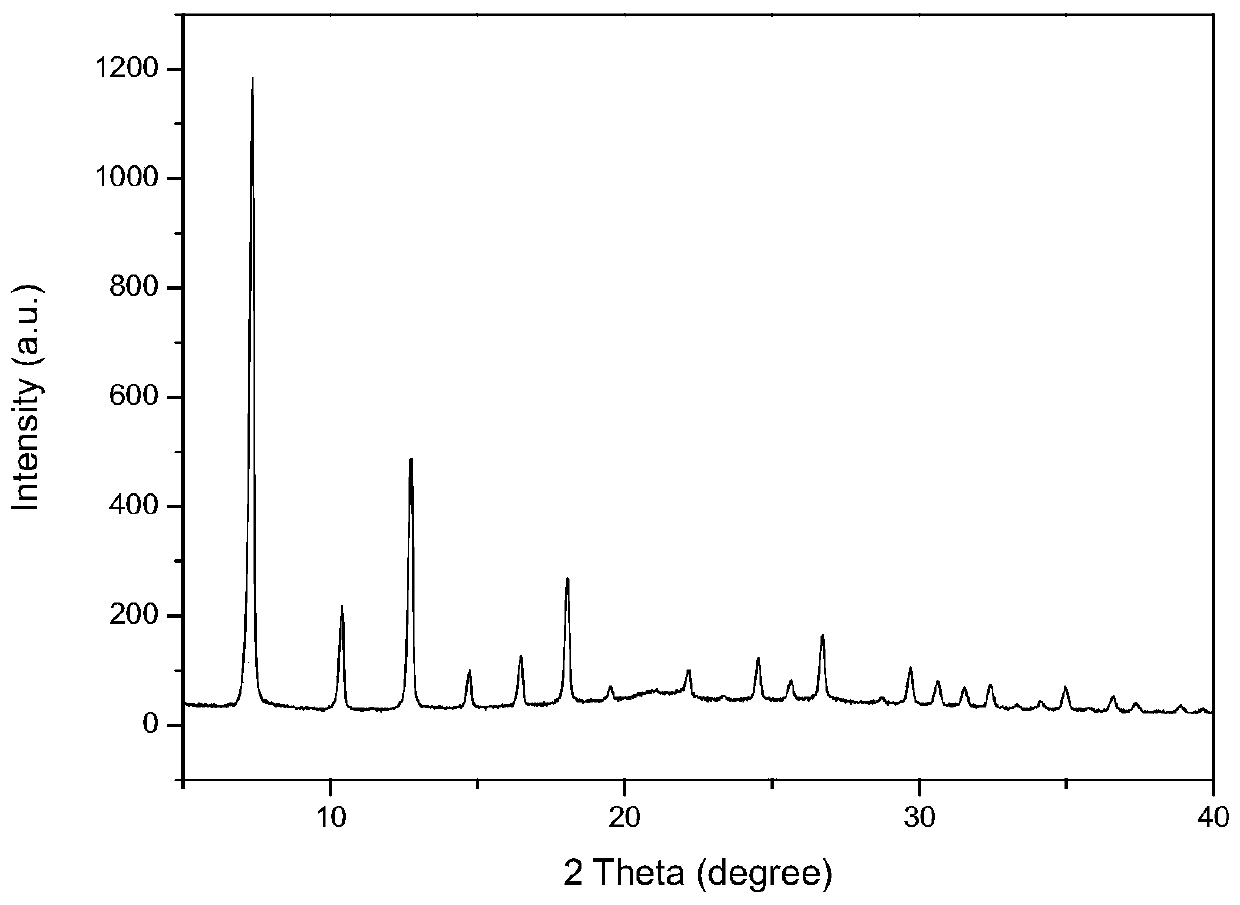

Preparation method of carboxyl-terminated hyperbranched polyesteramide collagenous fiber adsorbing material

ActiveCN103394335AUnique structureOvercome the disadvantage of being difficult to separate from water bodiesOther chemical processesWater contaminantsFiberTurbidity

The invention discloses a preparation method of a carboxyl-terminated hyperbranched polyesteramide collagenous fiber adsorbing material. The preparation method comprises the following steps of: adding carboxyl-terminated hyperbranched polyesteramide collagenous fiber into water, and stirring at normal temperature for uniform dispersion to obtain a carboxyl-terminated hyperbranched polyesteramide collagenous fiber dispersive liquid; then adjusting the pH value of glyoxylic acid aqueous solution to be 5.5-8.0, then adding the glyoxylic acid aqueous solution into the carboxyl-terminated hyperbranched polyesteramide collagenous fiber dispersive liquid, continuously reacting for 3.0-5.0 hours at the temperature of 0-40 DEG C, obtaining turbid liquid containing products, then filtering, drying and grinding a filter cake uniformly to obtain the carboxyl-terminated hyperbranched polyesteramide collagenous fiber adsorbing material. The carboxyl-terminated hyperbranched polyesteramide collagenous fiber adopted by the invention has a large amount of active groups, can be chelated with metal ions and is prepared into the carboxyl-terminated hyperbranched polyesteramide collagenous fiber adsorbing material under the action of a carboxylation reagent; and the carboxyl-terminated hyperbranched polyesteramide collagenous fiber adsorbing material has higher adsorbing performance, wider pH addition range and stronger adaptability to the change of multi-turbidity, alkalinity and the content of organic matters.

Owner:SHAANXI UNIV OF SCI & TECH

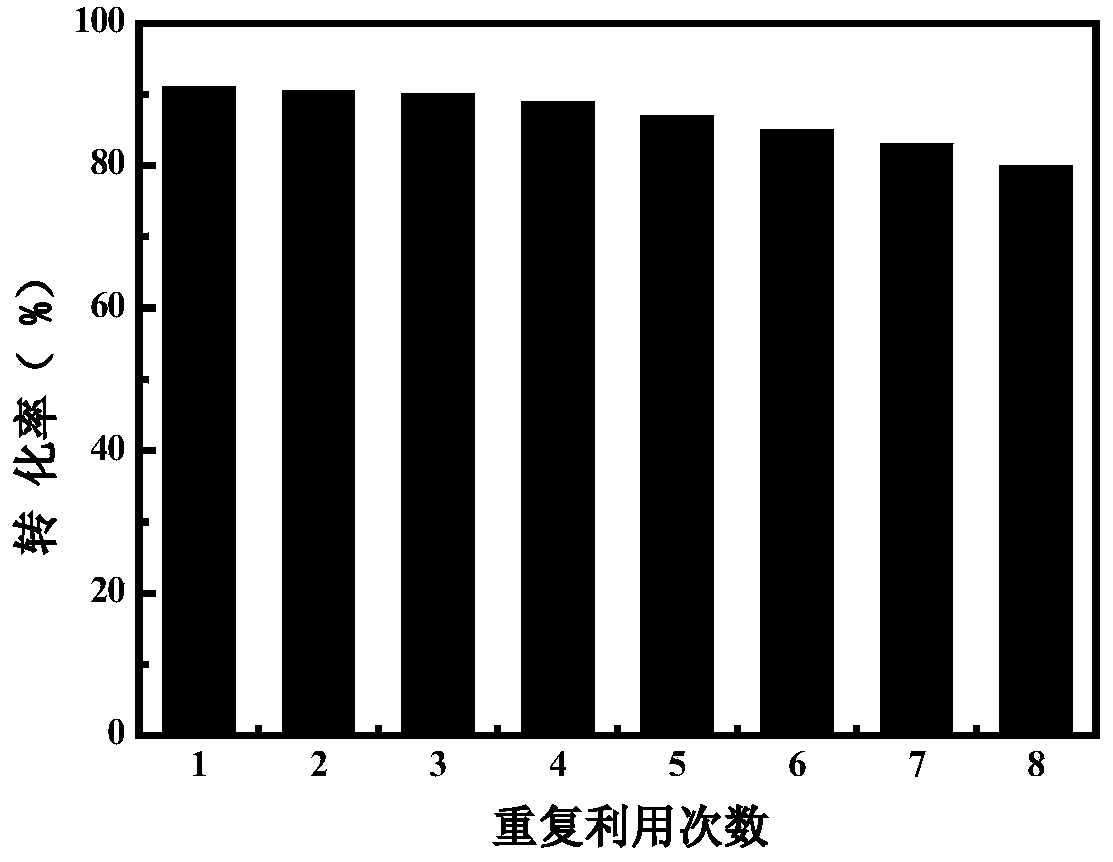

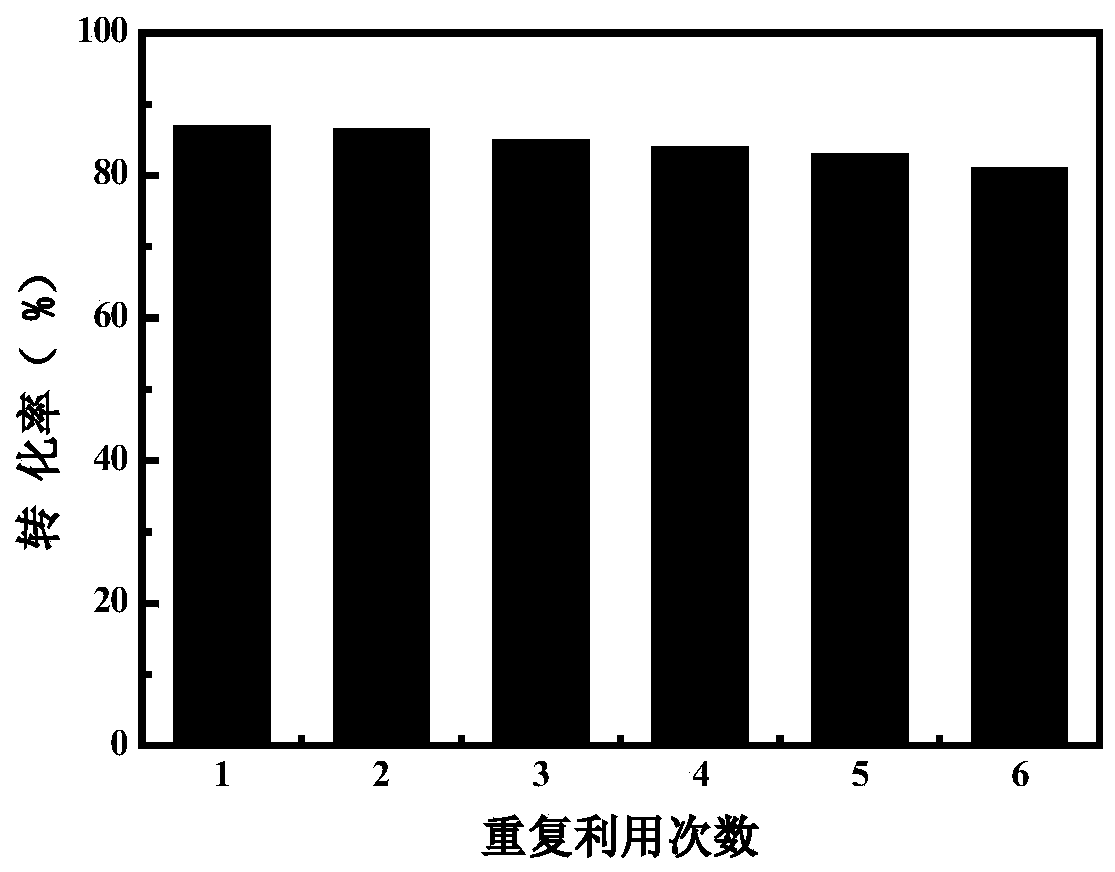

ZIF@TU-POP composite catalyst, and preparation method and application thereof

ActiveCN111215148AThe process preparation method is simpleRaw materials are easy to getOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystSulfite salt

The invention belongs to the technical field of chemical catalytic materials, and particularly provides a ZIF@TU-POP composite catalyst, and a preparation method and an application thereof. The preparation method comprises the following steps: adding urea, a sodium sulfite solution and acetic acid into deionized water containing phenylenediamine, stirring for 24-36 h at 90-120 DEG C, filtering, washing, and carrying out vacuum drying to obtain 1,3-bis(4-aminophenyl)urea; adding 1,3-bis(4-aminophenyl)urea, cyanuric chloride and a ZIF material into dry dimethyl sulfoxide, reacting at 15-25 DEG C, adding N,N-diisopropylethylamine, stirring, adding a crude product into ice to form a solid after the reaction is finished, filtering, and sequentially washing with dichloromethane, tetrahydrofuranand ethyl acetate to obtain the target product. The ZIF@TU-POP composite catalyst catalyzes epoxypropane and carbon dioxide to generate cyclic carbonate, the highest yield can reach 99%, and the conversion rate can still reach 90% or above after the catalyst is repeatedly used for four times.

Owner:LIAONING UNIVERSITY

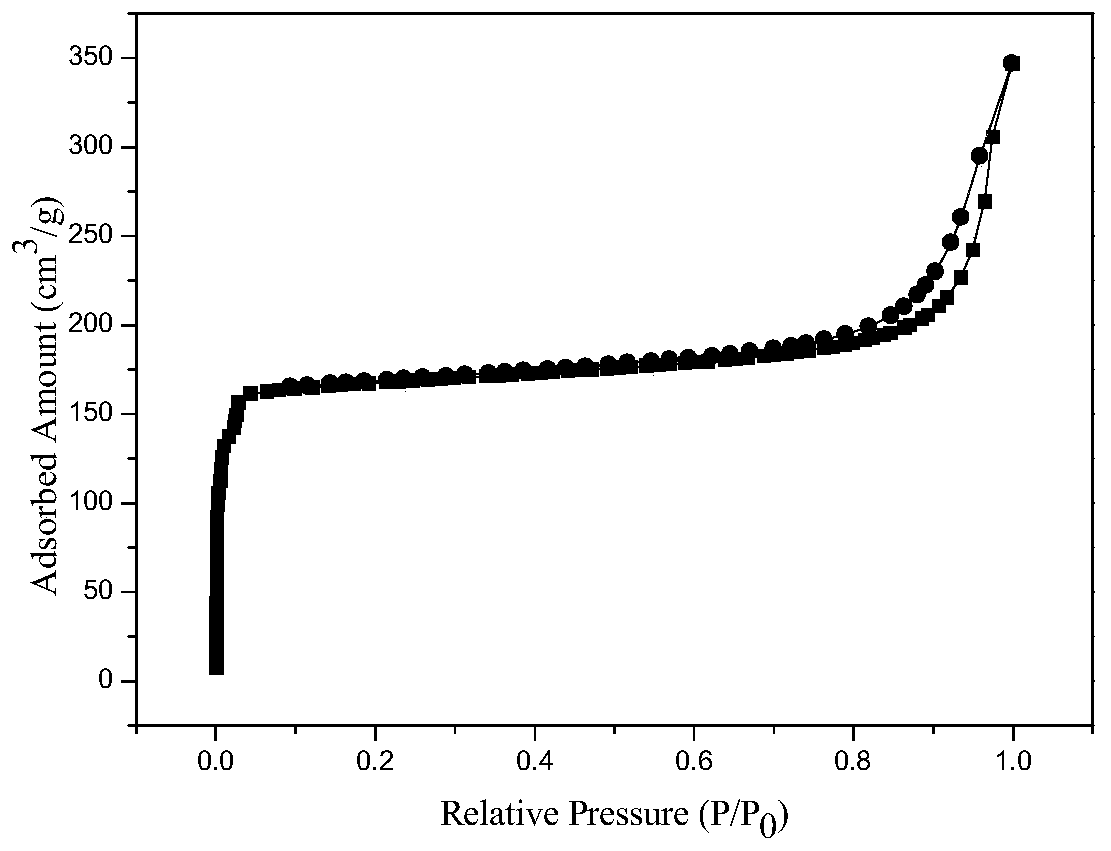

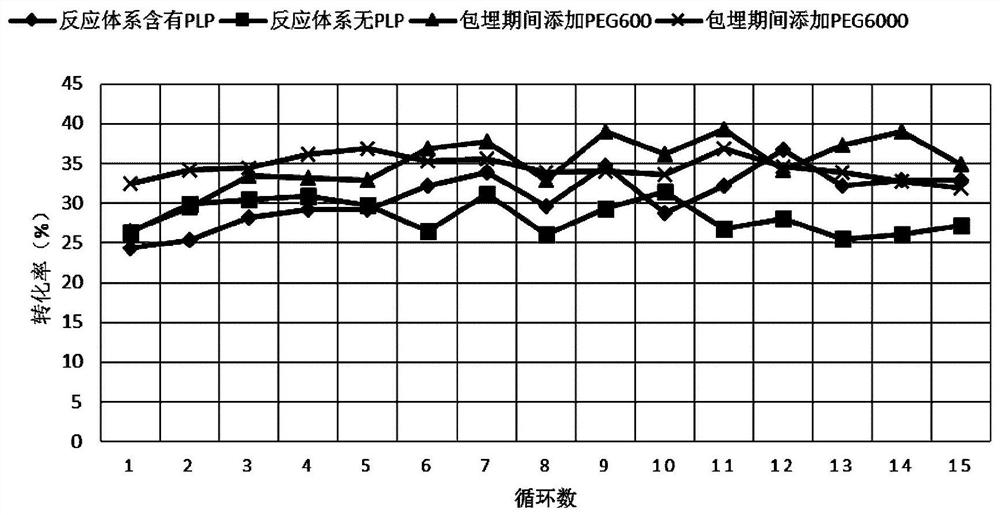

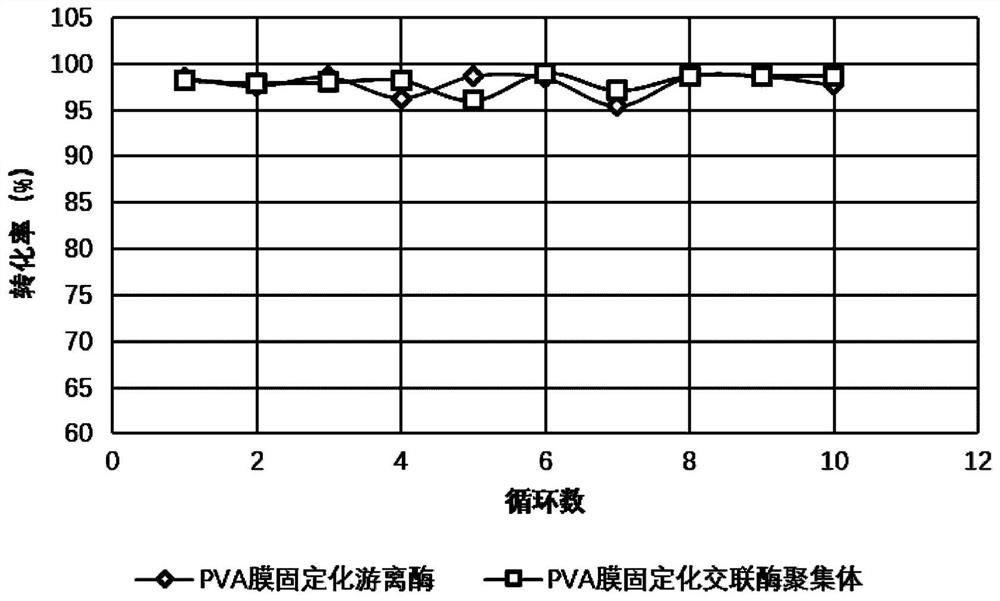

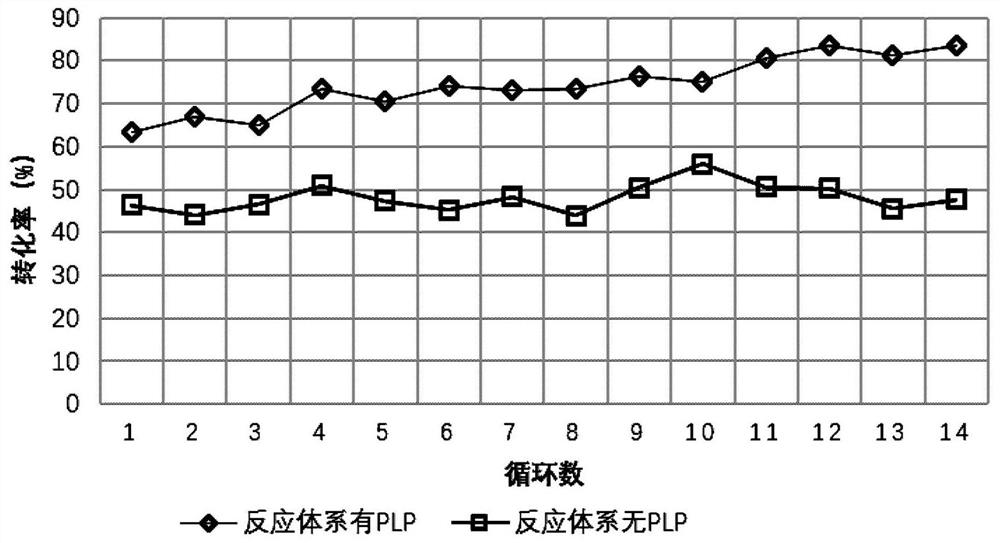

PVA membrane immobilized enzyme and preparation method thereof

InactiveCN113337496AWide applicabilityIncrease loadOn/in organic carrierCyclohexanoneCyclohexanone monooxygenase

The invention provides a PVA membrane immobilized enzyme and a preparation method thereof. The PVAfilm immobilized enzyme comprises a PVA porous membrane and an enzyme embedded on the PVA porous membrane, the PVA porous membrane is a three-dimensional structured PVA porous membrane, and the enzyme is selected from any one of transaminase, D-lactic dehydrogenase, cyclohexanone monooxygenase, ketoreductase, enoyl reductase, nitrilase, ammonia lyase, amino acid dehydrogenase, imine reductase, alcohol dehydrogenase, ammonium formate dehydrogenase, glucose 1-dehydrogenase and mutants thereof. The three-dimensional structured PVA porous membrane is adopted as a carrier to immobilize enzyme in an embedding manner, the embedding immobilization process is simple, the conditions are mild, the specific surface area is large, and the enzyme is relatively stable after being embedded and immobilized in the PVA porous membrane and is not easy to leach in the use process; and the porous structure of the PVA porous membrane can better transfer reactants and products, is suitable for being used in continuous flow biochemical catalysis, and has wide adaptability to enzymes.

Owner:ASYMCHEM LIFE SCI TIANJIN

Arsenic passivator and application thereof

InactiveCN108085016APromote passivationPassivation does not affectContaminated soil reclamationOrganic fertilisersPyrolusiteSodium Bentonite

The invention provides an arsenic passivator and an application thereof. The arsenic passivator comprises an agent A and an agent B, wherein the agent A is prepared from raw materials in parts by weight as follows: 40-60 parts of polyferric sulfate, 45-65 parts of ferrous sulfate and 0-15 parts of sodium humate; the agent B is prepared from raw materials in parts by weight as follows: 20-35 partsof pyrolusite powder, 25-45 parts of calcium bentonite and 30-50 parts of slaked lime, and the agent A and the agent B of the arsenic passivator are used in a mass ratio being 1:1. Compared with the prior art, the arsenic passivator is applied to passivation treatment of arsenic in soil and solid waste, does not affect pH of a system basically, has the advantages of being low in reagent dosage, good in treatment effect, high in treatment stability and environmentally friendly, taking effect quickly, realizing simple and convenient engineering operation and the like, and is low in comprehensivecost and wide in applicable range.

Owner:芜湖格丰环保科技研究院有限公司 +1

Lead-free soldering tin wire

InactiveCN103586599AEasy to leachReduce the phenomenon of lead poisoningWelding/cutting media/materialsSoldering mediaCopper wireCopper-wiring

The invention discloses a lead-free soldering tin wire. The lead-free soldering tin wire is characterized by comprising, by mass, 1.5-8% of Cu, 0.01-2% of Co, 0.01-1% of Ni, and the balance Sn. The liquidus temperature of the lead-free soldering tin wire is 420 DEG C or below 420 DEG C. The lead-free soldering tin wire can further comprise one or more oxidation inhibition elements and / or one or more wetting improvement elements, and a composition of P, Ge and Ga or a composition with 0.05-2% of Ag by mass can be selected and used as the wettability improvement elements. The lead-free soldering tin wire coats the end portion of a copper wire coil. The lead-free soldering tin wire has the advantages that the lead-free soldering tin wire can not be subjected to copper leaching easily when being used in a molten state, the phenomenon of lead poisoning can be reduced, and the lead-free soldering tin wire is practical and convenient to use.

Owner:NINGBO YINZHOU HENGXUN ELECTRONICS MATERIALS

Geological polymer prepared based on domestic sludge and thermal-insulation and sound-insulation humidity-regulating plate

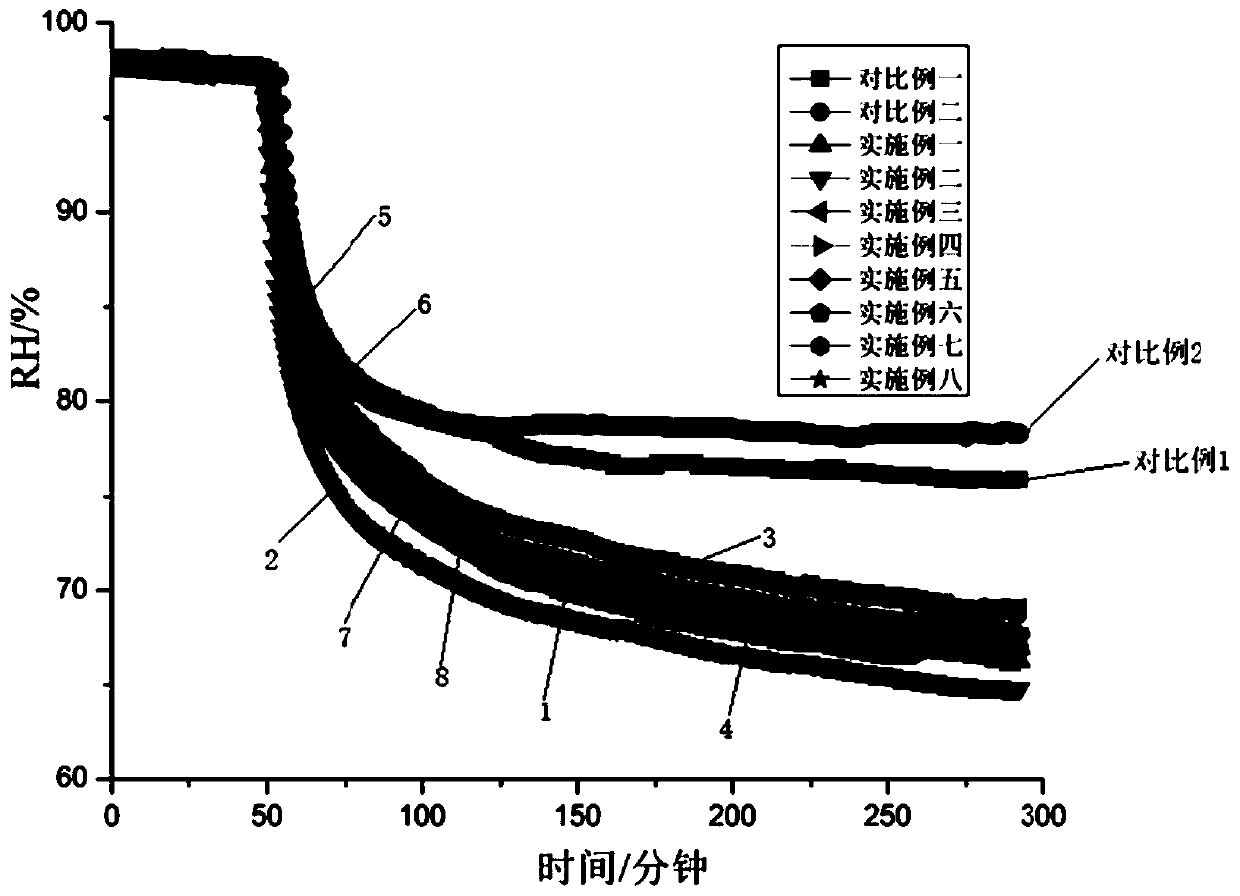

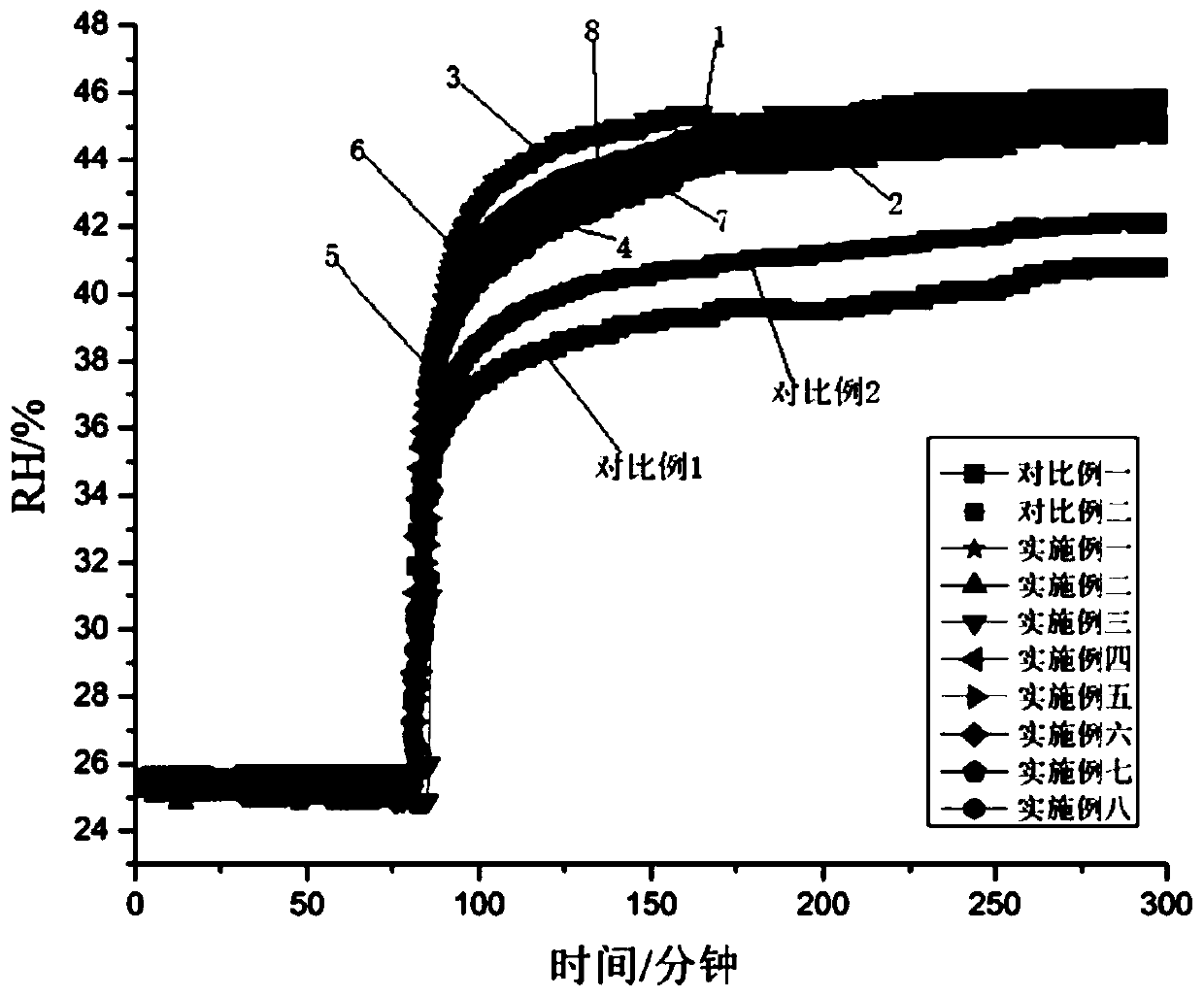

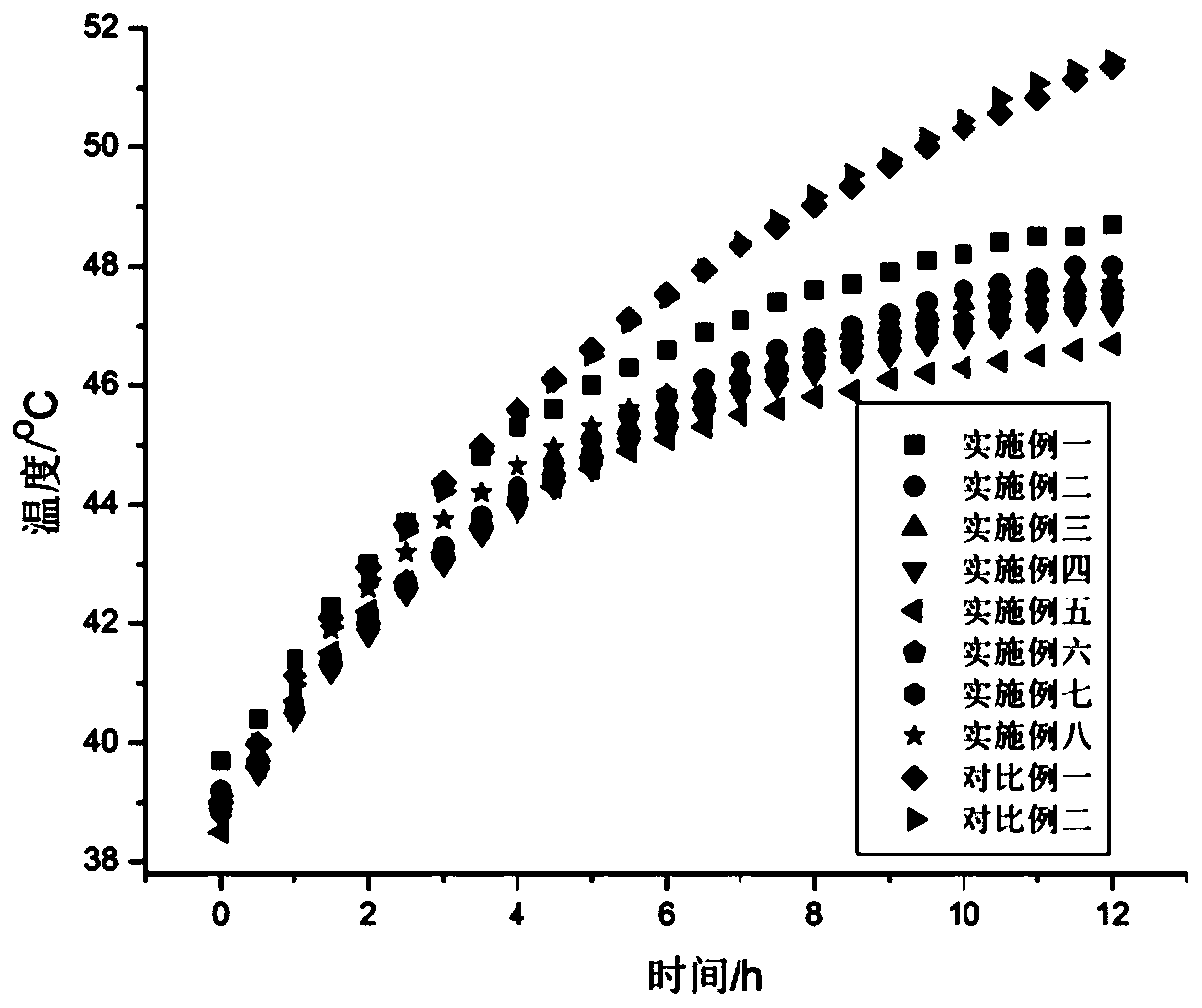

ActiveCN110590200AThe reaction process is compactImprove toughnessCement productionPolymer scienceSludge

The invention belongs to the technical field of solid waste treatment, and particularly relates to a geological polymer prepared based on domestic sludge and a thermal-insulation and sound-insulationhumidity-regulating plate, and further discloses a preparation method of the geological polymer and a preparation method of the thermal-insulation and sound-insulation humidity-regulating plate. According to the geological polymer prepared based on the domestic sludge, the domestic sludge is directly matched with fly ash, the appropriate silicon-aluminum ratio of the system is adjusted by adding asilicon source material, and organic matters are added, so that a lightweight geological polymer is obtained. The thermal-insulation and sound-insulation and humidity-regulating plate is prepared bytaking the geological polymer as a raw material in a conventional manner, and the plate has relatively high silencing, heat insulation and humidity adjusting performance, and can be widely applied tothe field of functional building decoration.

Owner:淮南领菲科技有限公司

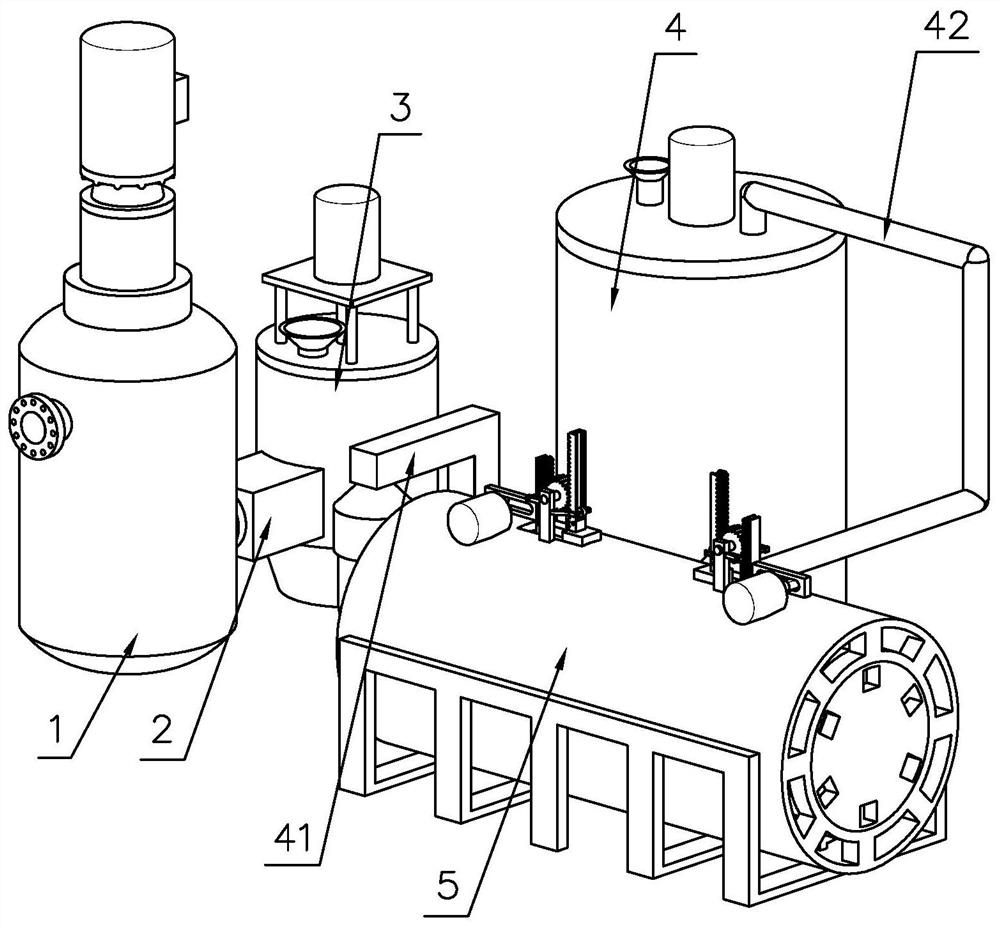

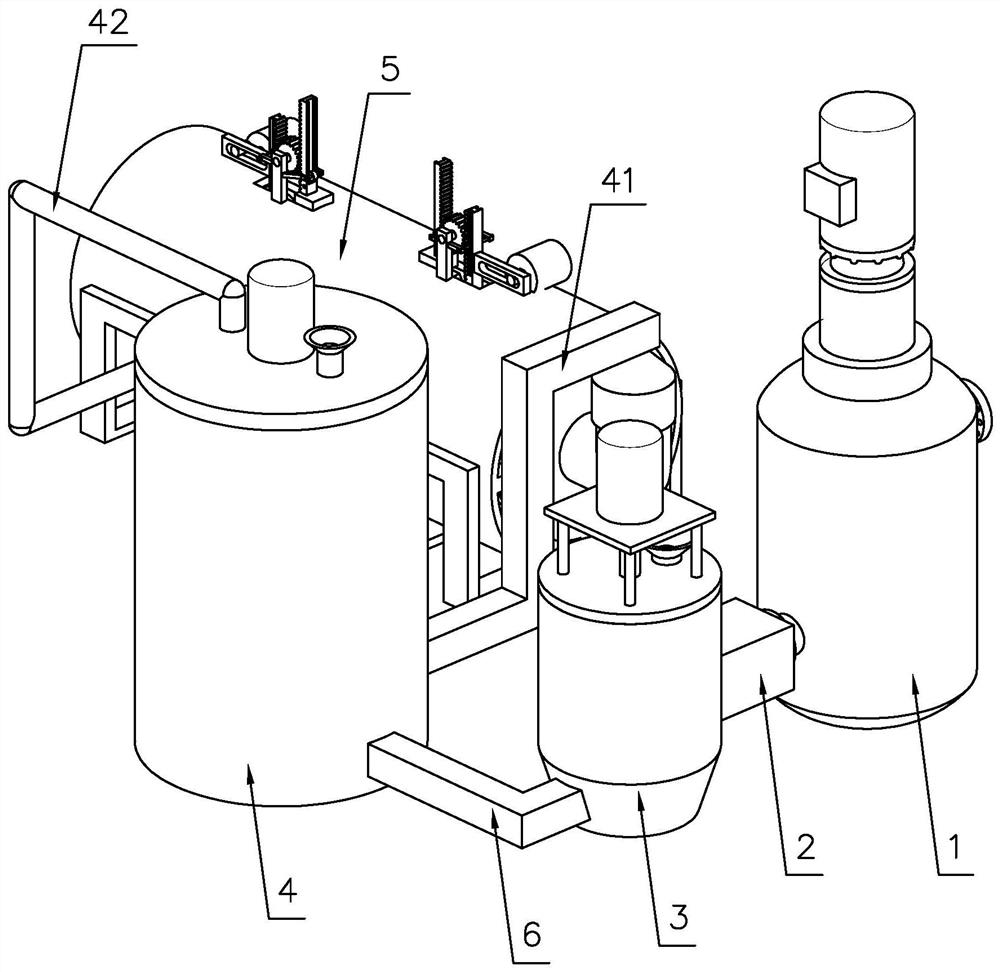

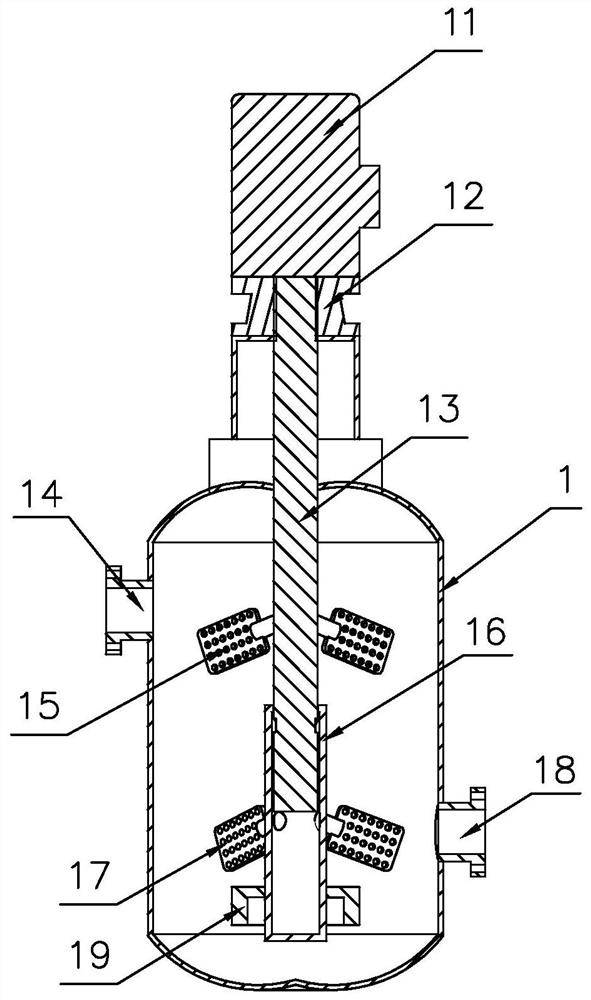

Preparation device and preparation method of hydrophobic slow-release organic-inorganic compound fertilizer

PendingCN112939670AReduce solubilitySlow decompositionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSpray GranulationSoil science

The invention discloses a preparation device and a preparation method of a hydrophobic slow-release organic-inorganic compound fertilizer, the preparation device of the hydrophobic slow-release organic-inorganic compound fertilizer comprises an activation reaction kettle, a material conveying channel I, a compounding tank, a buffer tank, a spraying granulation dryer and a material conveying channel II; according to the invention, the hydrophobic agent is coated to form a plurality of hydrophobic layer films in the fertilizer particles, so that the pores of the fertilizer particles are blocked, the surface wetting angle of the fertilizer particles is increased, water in soil is not easy to wet the interiors of the fertilizer particles, and water-soluble inorganic nutrients in the fertilizer are not leached; and inorganic nutrients are gradually released from outside to inside only along with gradual decomposition and utilization of organic matters from outside to inside, and the hydrophobic slow-release organic-inorganic compound fertilizer can have multiple nutrient proportions from outside to inside through slurry with multiple nutrient proportions and multi-layer spraying granulation.

Owner:山东奥德鲁生物科技有限公司

Hydrogen catalyzed alkyl halide dehaloginating reducton process for preparing hydrocarbon

InactiveCN1974498ANo pollution in the processMild conditionsCatalyst carriersHydrocarbon from halogen organic compoundsHydrogenReaction temperature

The present invention discloses catalyzed hydrogen reduction process of alkyl halide to dehaloginate and produce hydrocarbon. The process adopts alkyl halide as main material, inorganic palladium salt microcapsule as catalyst in the amount of 0.01-2 %, methanol and ethanol, n-hexane or tetrahydrofuran as solvent, and has hydrogen as reductant in 0.1-2.0 MPa introduced to react at 20-120 deg.c for 1-10 hr. The present invention has reuse of inorganic palladium salt microcapsule as catalyst, and possesses the advantages of no pollution, mild condition, high operation safety, easy separation of the catalyst for reuse, etc.

Owner:SOUTH CHINA UNIV OF TECH

Arsenic-removing material for water body and application thereof in treatment of arsenic-containing wastewater

InactiveCN108503007AGood removal effectEasy to leachWater treatment parameter controlWater contaminantsSodium BentoniteMaterials science

The invention discloses an arsenic-removing material for a water body and application thereof in treatment of arsenic-containing wastewater. The arsenic-removing material for the water body is prepared from an agent A and an agent B according to a mass ratio of 1 to 1, wherein the agent A is prepared by uniformly mixing 70 to 85 parts of polyferric sulfate, 15 to 25 parts of polyaluminium chloride, and 0 to 10 parts of sodium humate through a dry powder mixing machine; the agent B is prepared by uniformly mixing 55 to 70 parts of calcium-based bentonite and 30 to 50 parts of slaked lime through the dry powder mixing machine. The arsenic-removing material for the water body has the advantages that the arsenic-removing material can be widely applied to quickly and simply treat the arsenic-containing wastewater with various substrates and complicated form at site; the usage amount of material is small, the effect is outstanding, the stability is high, the environmental protection effect is realized, the cost is economic, the application range is wide, and the like.

Owner:芜湖格丰环保科技研究院有限公司

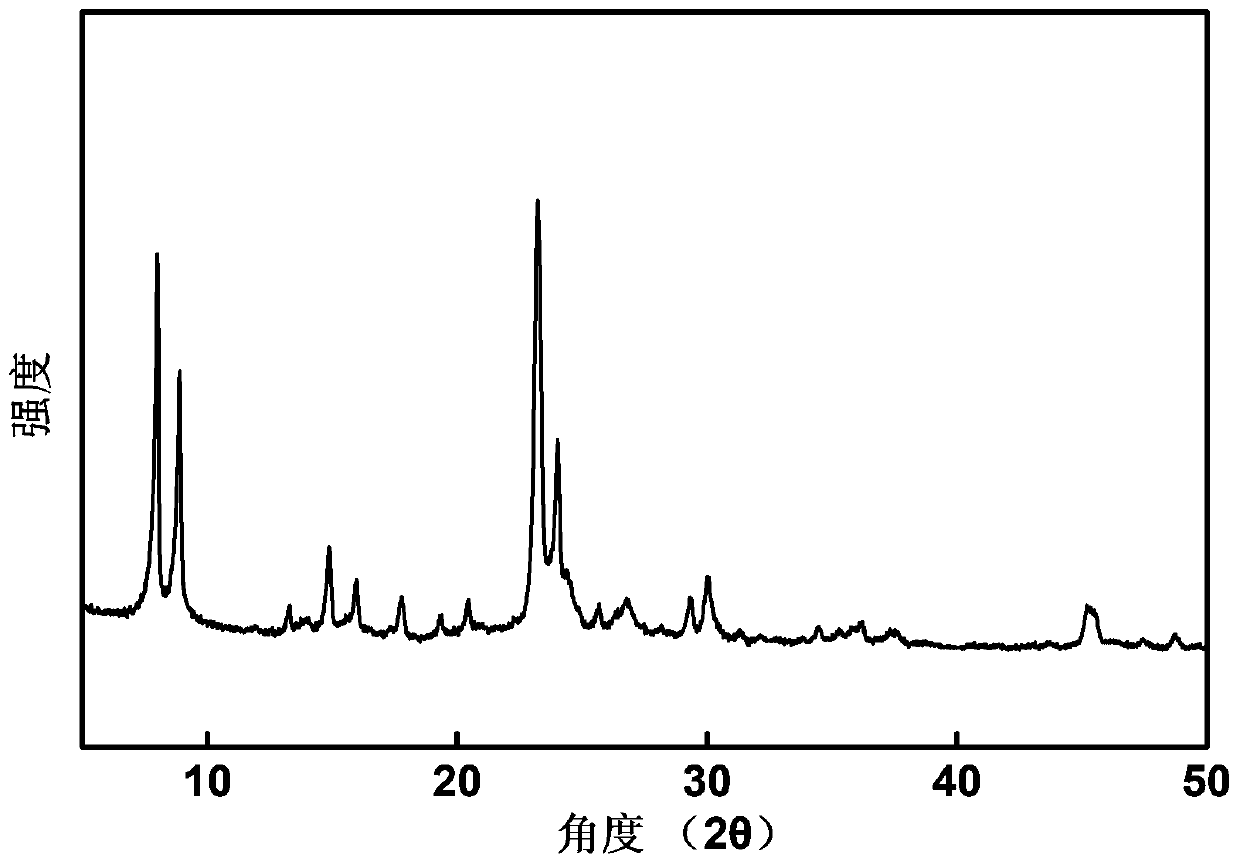

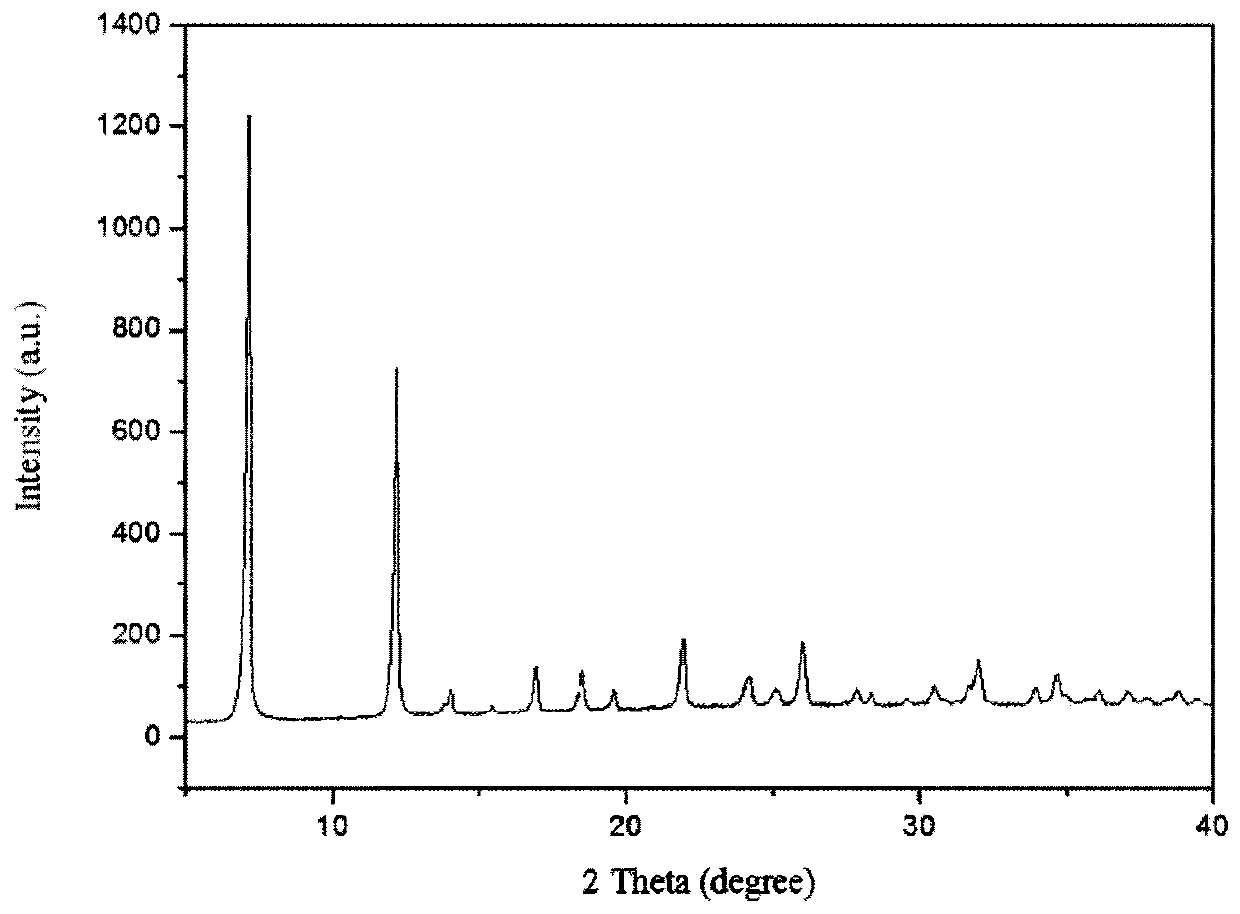

Bimetallic MEL molecular sieve as well as preparation method and application thereof

InactiveCN110560146AOvercome prone to reunionOvercome the problem of leachingMolecular sieve catalystsGalloaluminosilicates/ferroaluminosilicatesAlkyl transferMolecular sieve

The invention belongs to the technical field of molecular sieve materials, and particularly relates to a bimetallic MEL molecular sieve as well as a preparation method and application thereof. The bimetallic MEL molecular sieve has mesopores and micropores, and Cu and Fe are loaded in the mesopores and the micropores; wherein the silica-alumina ratio of the bimetallic MEL molecular sieve is 48-50.The bimetallic MEL molecular sieve is an H-MEL@ Cu / Fe bimetallic molecular sieve catalyst; the bimetallic MEL molecular sieve is provided with the mesopores and micropores, and has hierarchical porestructure, Cu and Fe metals are not easy to leach in the molecular sieve skeleton; the bimetallic MEL molecular sieve can be used as a catalyst and can show excellent catalytic performance in a Friedel-Crafts alkylation reaction of trimethylbenzene and benzyl alcohol, and the Cu and Fe bimetallic synergistic effect can improve the alkylation activity and the selectivity, so that the application prospect of the molecular sieve catalyst in the field of chemical engineering is broadened.

Owner:GUANGDONG UNIV OF TECH

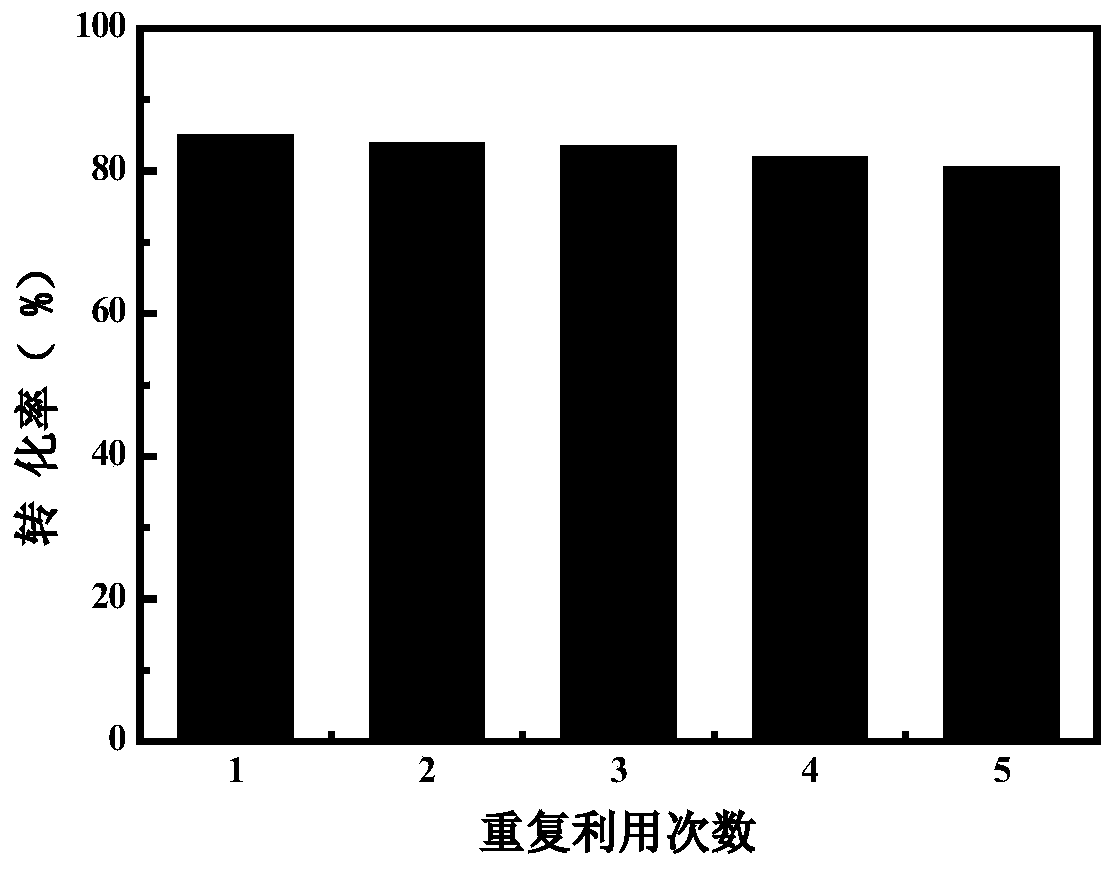

MOF@POP-n composite catalyst, preparation method and application thereof

ActiveCN111215149AThe process preparation method is simpleSave raw materialsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCarbonate ester

The invention relates to an MOF@POP-n composite catalyst, a preparation method and application thereof, and belongs to the technical field of chemical catalytic materials. The preparation method comprises the following steps of: dissolving cyclite in toluene to obtain a solution A, dissolving 1-vinylimidazole in toluene to obtain a solution B, mixing the solution A and the solution B uniformly, performing heating for 12-24h at 100-120DEG C in an N2 atmosphere, and conducting cooling, filtering, and washing to obtain a precursor; and adding the precursor, divinyl benzene and MOF into an N, N-dimethylformamide solution containing azodiisobutyronitrile, carrying out ultrasonic treatment for 15-45min, performing heating for 24-48h in a nitrogen atmosphere at 120-160DEG C, conducting cooling toroom temperature, and performing separation to obtain the target product. The MOF@POP-n composite catalyst catalyzes epoxypropane and carbon dioxide to generate cyclic carbonate, the highest yield can reach 98%, and the conversion rate can still reach 90% or above after the MOF@POP-n composite catalyst is repeatedly used six times.

Owner:LIAONING UNIVERSITY

Method for selectively extracting and separating vanadium from vanadium-molybdenum waste residues

ActiveCN112899483AEffective dissolutionNot easy to dissolveProcess efficiency improvementSulfite saltAmmonium metavanadate

The invention relates to a method for selectively extracting and separating vanadium from vanadium-molybdenum waste residues. According to the technical scheme, the method comprises the following steps that sodium carbonate, sodium sulfite and vanadium-molybdenum waste residue powder are mixed according to the mass ratio of (0.1-0.2): (0.01-0.03): 1 to obtain a reaction raw material; the reaction raw material and water are put into a reaction tank according to the solid-to-liquid ratio of 1: (1-2.5) kg / L, and stirring lasts for 2-6 hours under the conditions of 25-45 DEG C and 80-200r / min to obtain slurry after reaction; solid-liquid separation is carried out on the reacted slurry to obtain vanadium-containing leachate and leaching residues; oxygen is introduced into the vanadium-containing leachate for oxidation, and oxidized vanadium-containing leachate is obtained; and then 0.015-0.035 kg of ammonium chloride is added into each liter of the oxidized vanadium-containing leachate, stirring is conducted for 1-2 h, and ammonium metavanadate is prepared. The method has the advantages of being simple in vanadium extraction process, short in process flow, low in energy consumption and good in vanadium-molybdenum separation effect.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com