Method for fixing metal oxide by using polyurea microcapsule

A technology of oxides and microcapsules, which is applied in the direction of microcapsule preparations, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high preparation costs, unseen metal oxide-containing polyurea microcapsules, and microcapsule breakage rate and the size is difficult to control, etc., to achieve the effect of simple preparation method, stable activity and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

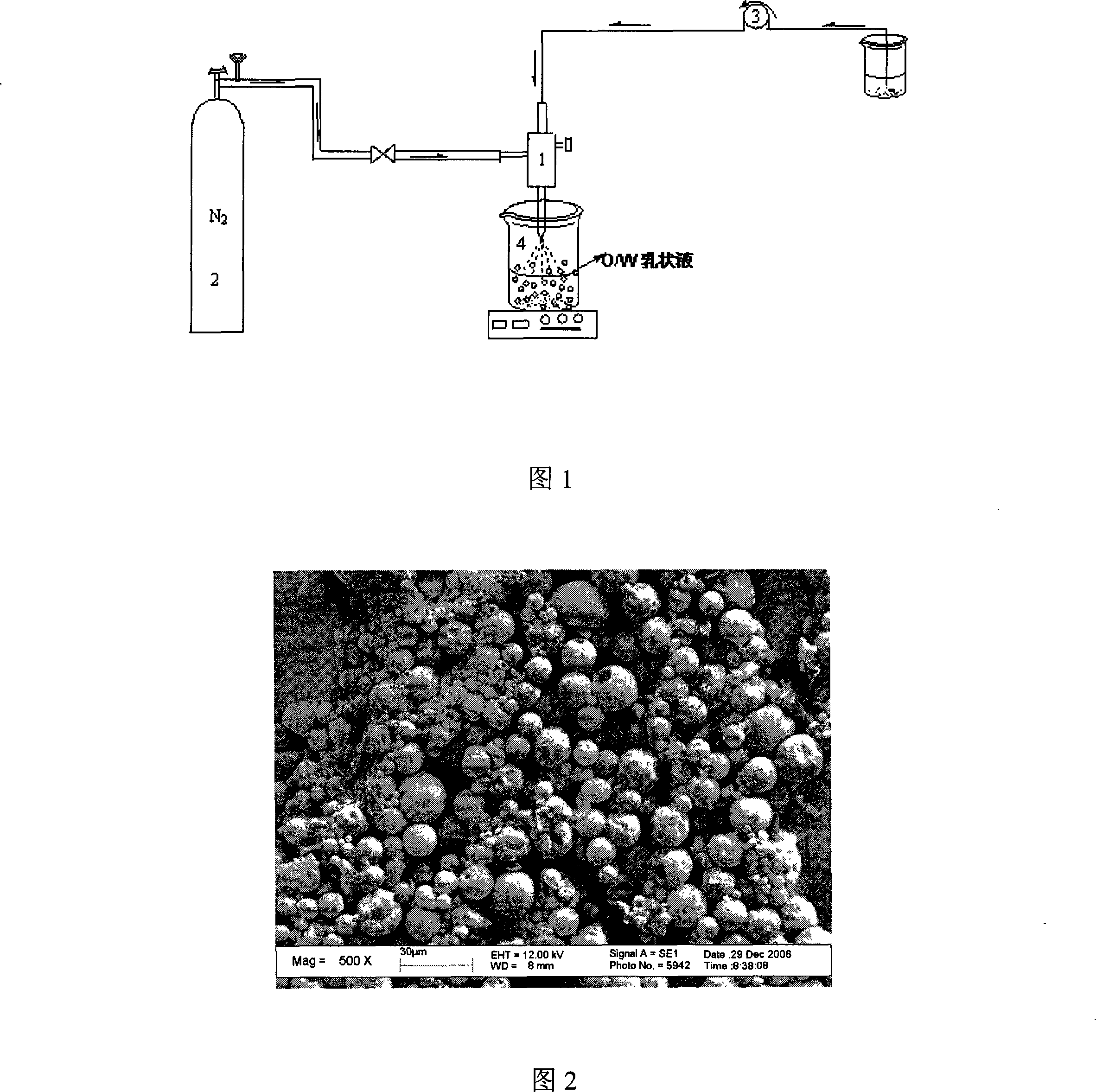

[0026] Weigh 3.0g of styrene-maleic anhydride copolymer (SMA) and dissolve it in 40mL of deionized water to prepare solution A; add 4.0g of toluene 2,4-diisocyanate (TDI) to 15mL of cyclohexane, 2.0g of Span- 80 (i.e. sorbitan monooleate) and 0.1g magnesium oxide, ultrasonically dispersed for 20 minutes to prepare suspension B; then 2 As a carrier gas, use a peristaltic pump (BTW50 / JY1015) to pump suspension B into a nebulizer (WNA-4-1F2B2, the inner capillary diameter of the nebulizer is 400 μm) at a flow rate of 4 mL / min, and spray into solution A after nebulization A stable O / W emulsion was formed in the medium, and a rapid interfacial polymerization reaction occurred at the same time; after the reaction was carried out for 6 hours, the resulting suspension was concentrated under reduced pressure to obtain a solid powder. The obtained solid powder was washed successively with 95% ethanol and acetone, and air-dried naturally to obtain microcapsules (MgOEn) immobilized with m...

Embodiment 2

[0028] Weigh 2.0g SMA and dissolve it in 10mL deionized water to prepare solution A; add 3.5g TDI, 1.5g Span-80 and 0.1g titanium oxide to 10mL cyclohexane, and ultrasonically disperse for 20 minutes to prepare suspension B; then to N 2 As a carrier gas, use a peristaltic pump to pump the suspension B into the nebulizer at a flow rate of 10 mL / min (the inner capillary diameter of the nebulizer is 500 μm), and spray it into the solution A after atomization to form a stable O / W emulsion. A rapid interfacial polymerization reaction occurred; after the reaction was carried out for a certain period of 6 hours, the resulting suspension was concentrated under reduced pressure to obtain a solid powder. The obtained solid powder is washed with 95% ethanol and acetone in sequence, and air-dried to obtain microcapsules immobilized with titanium oxide.

Embodiment 3

[0030] Weigh 10.0g SMA and dissolve in 50mL deionized water to prepare solution A; add 10.0g isophorone diisocyanate IPDI, 5.0g Span-80 and 0.5g ruthenium dioxide to 30mL cyclohexane, and ultrasonically disperse for 20 minutes Suspension B was prepared; then with N 2 As a carrier gas, use a peristaltic pump to pump the suspension B into the nebulizer at a flow rate of 10 mL / min (the diameter of the inner capillary of the nebulizer is 450 μm), and spray it into the solution A after atomization to form a stable O / W emulsion. A rapid interfacial polymerization reaction occurred; after the reaction was carried out for a certain period of 6 hours, the resulting suspension was concentrated under reduced pressure to obtain a solid powder. The obtained solid powder is washed with 95% ethanol and acetone in sequence, and air-dried to obtain microcapsules immobilized with ruthenium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com