Multi-adsorption biodegradable foam with oil-water separation function

A technology for oil-water separation and adsorption of water, applied in the direction of adsorption of water/sewage treatment, separation methods, water pollutants, etc., can solve the problems of non-biodegradable, single function, and difficult recovery of adsorption materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

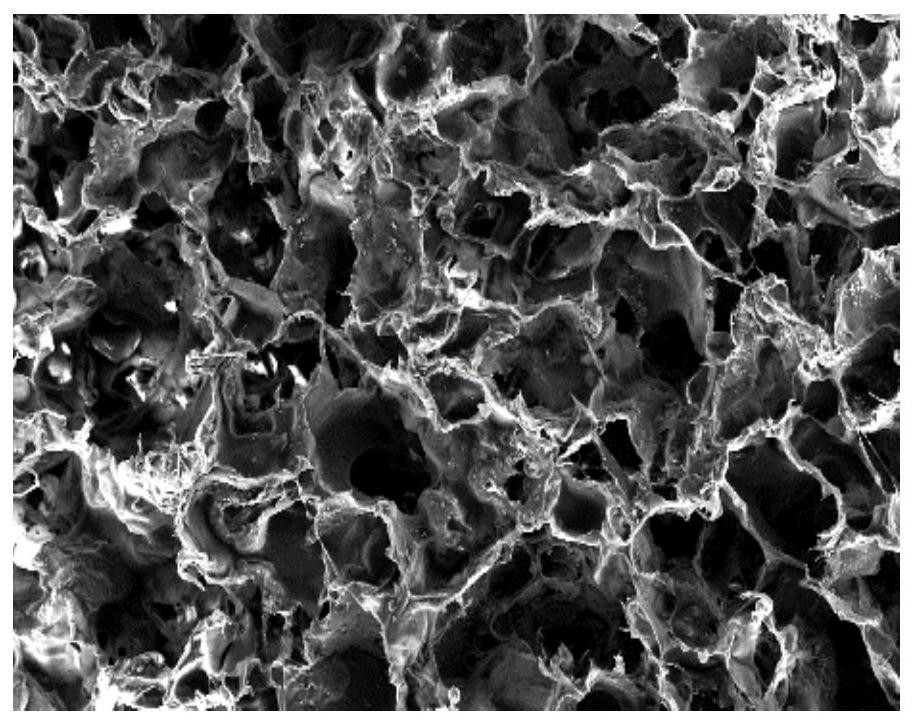

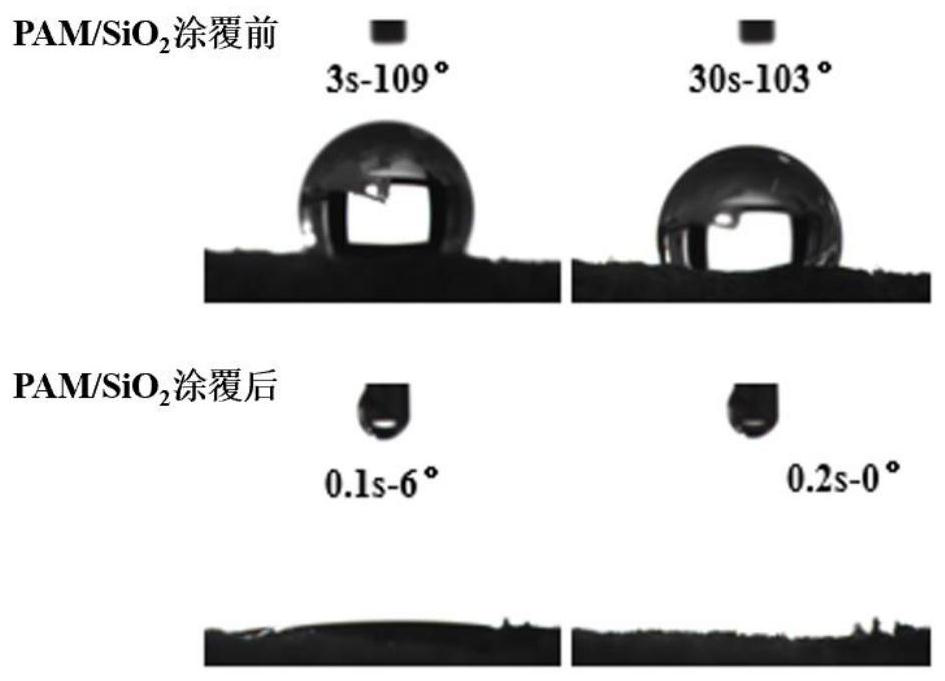

[0041] (1) Preparation of iron pillared bentonite: Dissolve 16.16g of ferric nitrate nonahydrate and 2.12g of sodium carbonate in 100mL of deionized water respectively, and then slowly dissolve sodium carbonate at a rate of 1mL / min under stirring in a water bath at 80°C. The solution was added dropwise into the ferric nitrate solution, stirred for 2 hours, placed at room temperature, and left to stand for 72 hours to obtain an iron pillar liquid; prepare 400 mL of bentonite deionized water dispersion with a mass fraction of 2%, and let the bentonite swell in deionized water for 12 hours After the iron pillar solution and the bentonite dispersion after swelling are all prepared, under stirring in a water bath at 80°C, slowly pour the iron pillar solution into the bentonite dispersion and continue to stir for 24 hours, then place the iron pillar product in Centrifuge in a centrifuge, discard the supernatant, continue to wash the bottom material with deionized water, and repeat th...

Embodiment 2

[0052] (1) Preparation of iron-pillared bentonite: same as step (1) of Example 1.

[0053] (2) Preparation of PBAT open-cell foam doped with 30wt% iron pillared bentonite: first 0.822g PBAT was completely dissolved in 5mL chloroform, then slowly added dropwise 4mL n-hexane in the process of rapid stirring, and the solution was When the phase separation occurs when it turns transparent to milky white, add 0.246g iron pillared bentonite, stir well, add sugar to fill the phase separation liquid, let it stand at room temperature for 12 hours, and then replace it with absolute ethanol three times. After the solvent is completely evaporated, use 60 ℃ water for several times to wash away the sugar inside the foam, that is, to obtain a PBAT open-cell foam doped with 30 wt% iron pillared bentonite.

[0054] (3) Surface treatment of PBAT open-cell foam doped with iron-pillared bentonite: same as step (3) of Example 1.

Embodiment 3

[0056] (1) Preparation of iron-pillared bentonite: same as step (1) of Example 1.

[0057] (2) Preparation of PBAT open-cell foam doped with 10wt% iron pillared bentonite: first 0.822g PBAT was completely dissolved in 5mL chloroform, then slowly added dropwise 4mL n-hexane in the process of rapid stirring, and the solution was When the phase separation occurs when it turns transparent to milky white, add 0.082g iron pillared bentonite, stir well, add sugar to fill the phase separation liquid, let it stand at room temperature for 12 hours, and then replace it with absolute ethanol three times. After the solvent is completely evaporated, use 60 ℃ water for several times to wash away the sugar inside the foam, that is, to obtain the PBAT open-cell foam doped with 10 wt% iron pillared bentonite.

[0058] (3) Surface treatment of PBAT open-cell foam doped with iron-pillared bentonite: same as step (3) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com