Method for removing phenolic substances in phenol aqueous solution by tyrosinase-metal organic framework compound

A metal-organic framework, tyrosinase technology, applied in the direction of immobilization on/in organic carriers, biochemical equipment and methods, chemical instruments and methods, etc., can solve the problem of low efficiency of phenolic substances, phenol removal technology Complex and other problems, to achieve the effect of efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

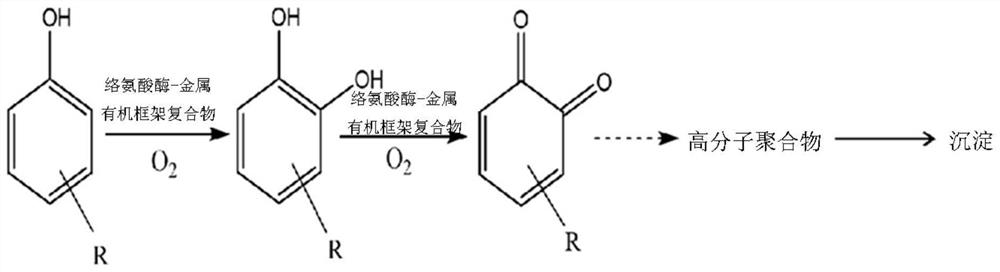

Method used

Image

Examples

Embodiment 1

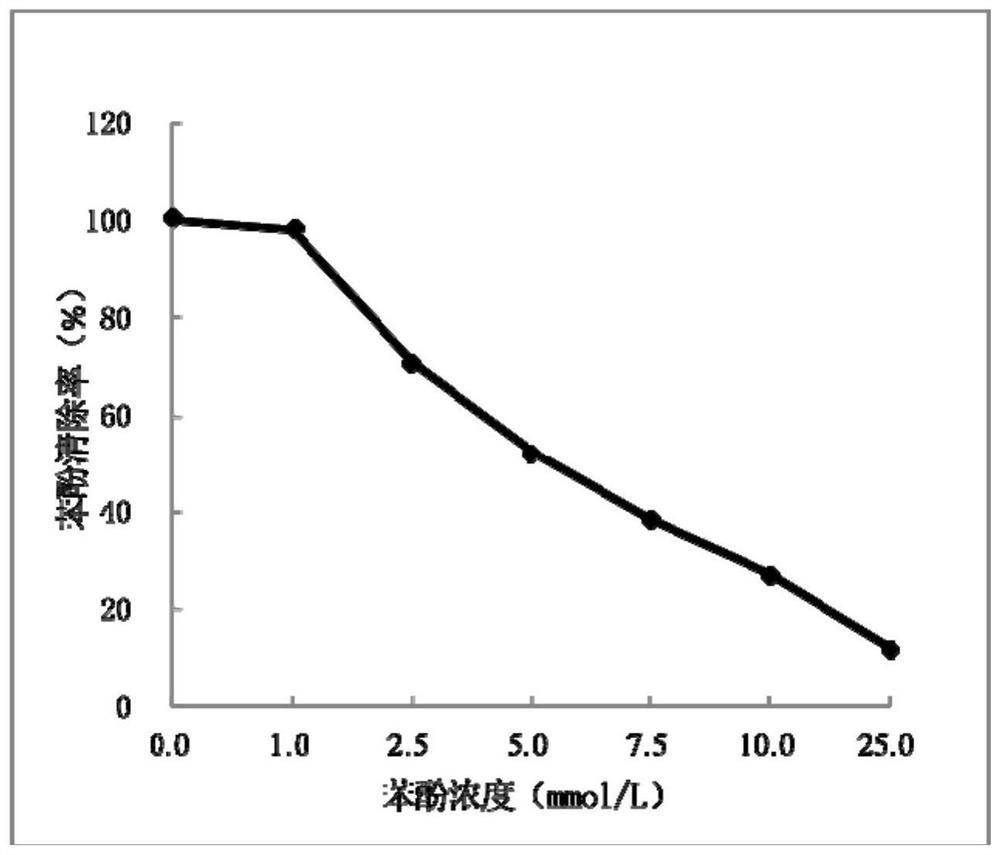

[0059] Exploring the effect of tyrosinase-metal-organic framework complex on the scavenging effect of different concentrations of phenol

[0060] Weigh 15 mg of tyrosinase-metal-organic framework complex into a 50 mL centrifuge tube, and then mix with the 10mL of phenol solution was reacted, reacted in a constant temperature shaker (30°C, 250rpm) for 2h, then sampled, analyzed by HPLC and calculated the clearance rate of different phenol concentrations, and each concentration made 3 parallel groups. The result is as figure 2 shown.

[0061] It can be seen from the results that the scavenging effect of tyrosinase-MOF complex on phenol solution decreases with the increase of phenol concentration, and the scavenging effect is better at low phenol concentration, but the scavenging effect is limited at high phenol concentration.

Embodiment 2

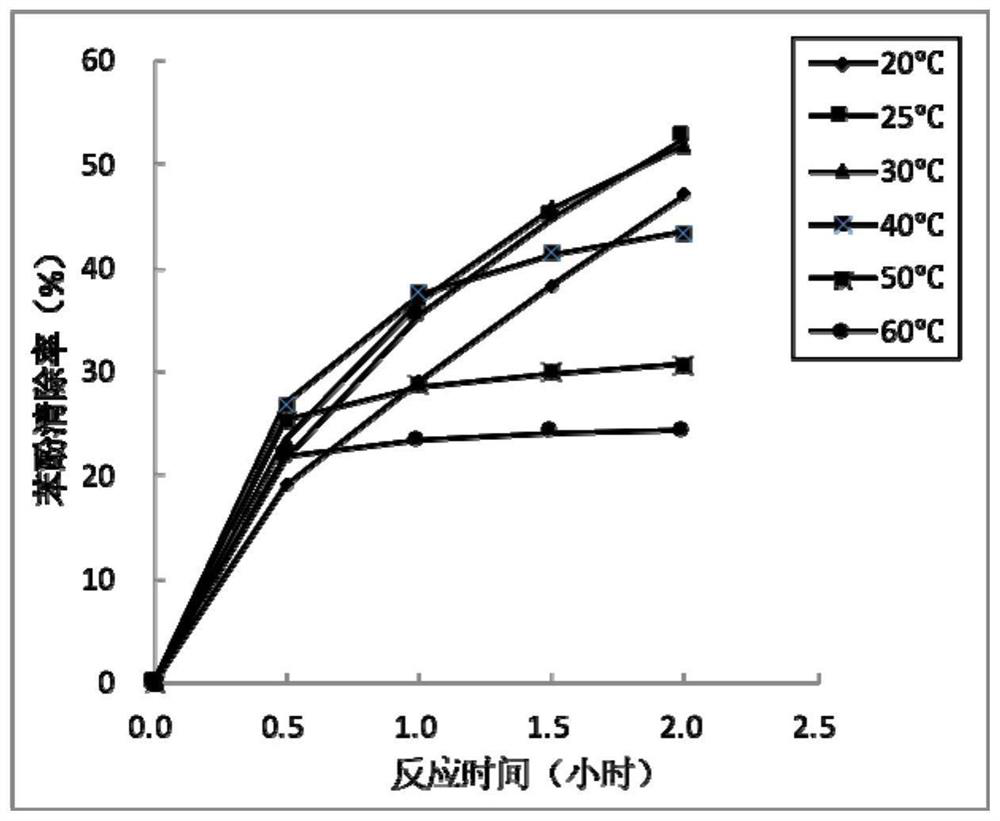

[0063] Exploring the effect of different temperatures on phenol scavenging by tyrosinase-metal-organic framework complexes

[0064] Weigh 30mg of tyrosinase-metal organic framework complex into a 50mL centrifuge tube, add 20mL, 2.5mmol / L phenol solution, and then ℃) constant temperature shaker (250rpm) co-reaction for 2h, sampling every 0.5h, using HPLC detection and analysis and calculation of phenol removal rate at different temperatures, each temperature made a total of 3 parallel groups. The result is as image 3 shown.

[0065] From the results, it can be seen that the effect of 20°C to 60°C on the removal of phenol by the tyrosinase-metal organic framework complex shows that the removal efficiency is the best in the range of 25°C to 30°C, and when it is higher than 40°C, high temperature leads to enzyme inactivation , the scavenging efficiency becomes lower, and 30°C is selected as the optimum temperature for tyrosinase-MOF complex to scavenge phenol.

Embodiment 3

[0067]Exploring the effect of different pH on phenol scavenging by tyrosinase-metal-organic framework complex

[0068] Weigh 35mg of tyrosinase-metal organic framework complex into a 50mL centrifuge tube, add 20mL, 2.5mmol / L phenol solution configured with different pH (5.0, 5.5, 6.0, 6.5, 7.0, 7.5, 8.0), and then The co-reaction was carried out on a constant temperature shaker (30°C, 250rpm) for 2 hours, and samples were taken every 0.5 hours. The clearance rate of phenol at different pH was calculated by HPLC, and 3 parallel groups were made for each pH. The result is as Figure 4 shown.

[0069] From the results, it can be seen that pH 5.0-8.0 has little effect on phenol scavenging effect of tyrosinase-metal-organic framework complex. The scavenging efficiency decreased slightly, and pH 6.0 was chosen as the optimum pH for tyrosinase-MOF complex to scavenge phenol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com