Method for stabilizing heavy metals in waste incineration fly ash through combination of coal gangue and calcium oxide

A waste incineration fly ash and domestic waste incineration technology, which is applied in the field of domestic waste incineration fly ash disposal, can solve the problems of low solidification efficiency of heavy metals, low cost, high energy consumption of high-temperature calcination, etc., and achieves good industrial application prospects and capacity reduction Good effect and high curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

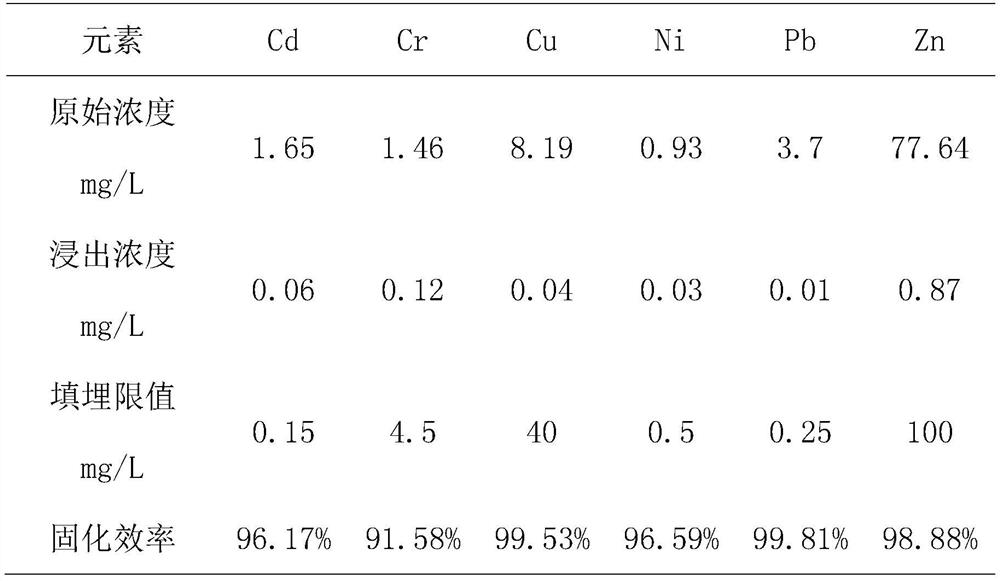

[0045] Raw material: domestic waste incineration fly ash to be treated, the original leaching concentration of excessive heavy metals in the fly ash is as follows: Cd1.65mg / L, Cr1.46mg / L, Cu8.19mg / L, Ni0.93mg / L, Pb3.70mg / L, Zn77.64mg / L.

[0046] Approach:

[0047] Step 1, according to domestic waste incineration fly ash: coal gangue: the ratio of calcium oxide=6:1:3 is fully mixed to obtain 100g material one;

[0048] Step 2, the NaOH of 50mL10% mass fraction and NaOH 2 SiO 3 Compound alkali solution (NaOH:Na 2 SiO 3 =1:2) was added to material 1, stirred for 0.5 hours to make it fully react, and obtained homogeneous slurry material 2;

[0049] Step 3: Inject material 2 into a 40*40*40mm mold with constant temperature and humidity (80°C, 80% relative humidity) for 1 day of curing, and after demoulding, indoor curing for 7 days to obtain fly ash-coal gangue-calcium oxide polymerization cured body.

[0050] The solid waste leaching toxic leaching method-acetic acid buffe...

Embodiment 2

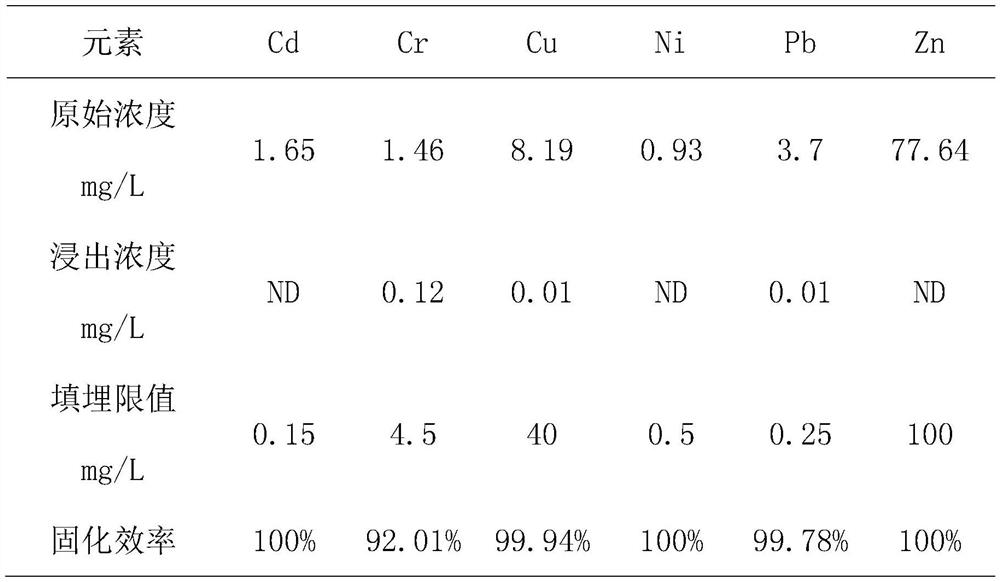

[0056] Raw material: domestic waste incineration fly ash to be treated, the original leaching concentration of excessive heavy metals in the fly ash is as follows: Cd1.65mg / L, Cr1.46mg / L, Cu8.19mg / L, Ni0.93mg / L, Pb3.70mg / L, Zn77.64mg / L.

[0057] Approach:

[0058] Step 1, according to domestic waste incineration fly ash: coal gangue: the ratio of calcium oxide=6:1:3 is fully mixed to obtain 100g material one;

[0059] Step 2, 75mL15% mass fraction NaOH and NaOH 2 SiO 3 Compound alkali solution (NaOH:Na 2 SiO 3 =1:2.5) was added to material 1, stirred for 0.5 hours to make it fully react, and obtained homogeneous slurry material 2;

[0060] Step 3: Inject material 2 into a 40*40*40mm mold with constant temperature and humidity (85°C, 90% relative humidity) for 1 day of curing, and after demoulding, indoor curing for 14 days to obtain fly ash-coal gangue-calcium oxide polymerization cured body.

[0061] The solid waste leaching toxic leaching method-acetic acid buffer so...

Embodiment 3

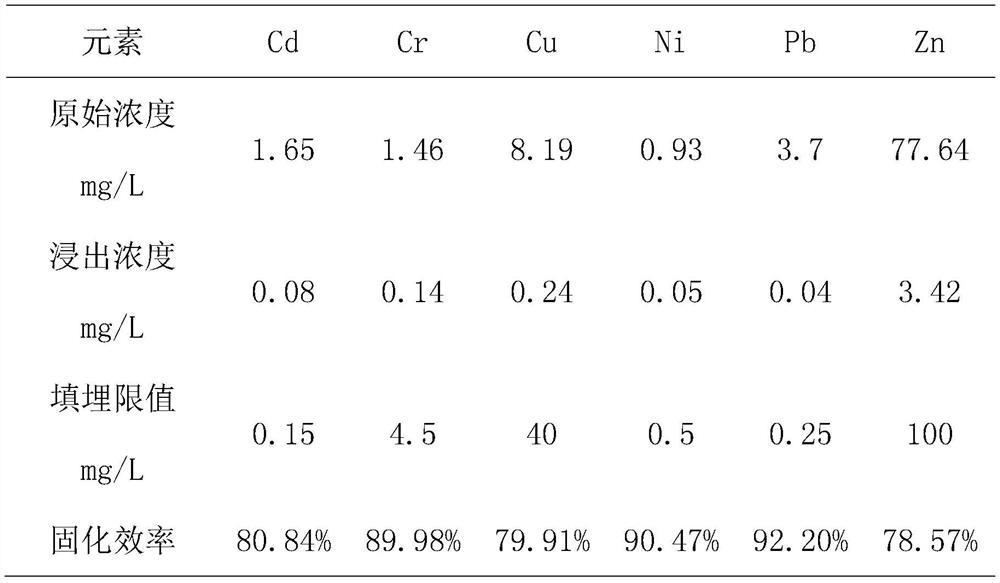

[0067] Raw materials: domestic waste incineration fly ash to be treated, the original leaching concentration of excessive heavy metals in the fly ash is as follows: Cd1.65mg / L, Cr1.46mg / L, Cu8.19mg / L, Ni0.93mg / L, Pb3.70mg / L L, Zn77.64mg / L.

[0068] Approach:

[0069] Step 1, according to domestic waste incineration fly ash: coal gangue: the ratio of calcium oxide=6:2:2 is fully mixed to obtain 100g material one;

[0070] Step 2, 50mL10% mass fraction NaOH and NaOH 2 SiO 3 Compound alkali solution (NaOH:Na 2 SiO 3 =1:2) was added to material 1, stirred for 0.5 hours to fully react among them, and obtained homogeneous slurry material 2;

[0071] Step 3: Inject material 2 into a 40*40*40mm mold with constant temperature and humidity (90°C, 95% relative humidity) for 1 day of curing, and after demoulding, indoor curing for 28 days to obtain fly ash-coal gangue-calcium oxide polymerization cured body.

[0072] The solid waste leaching toxic leaching method-acetic acid buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com