Automatic stacking system and method

An automatic stacking and stacking technology, applied in the field of stacking control, can solve the problems of stacking cranes that cannot be sorted and stacked, too many manual operations, and poor stacking quality. neat stacking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

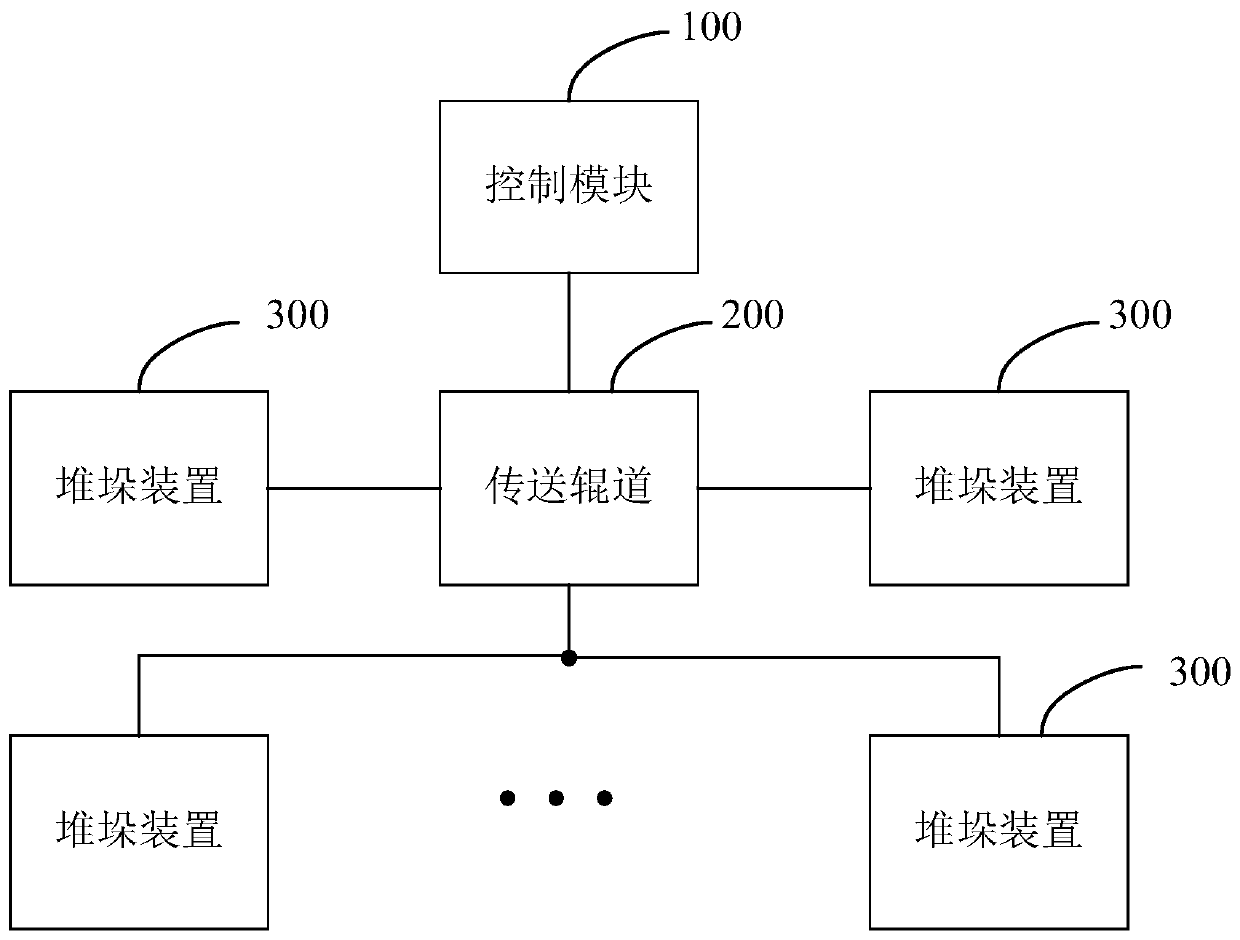

[0055] figure 1 A schematic structural view of an automatic stacking system of this embodiment is shown, and for convenience of description, only parts related to this embodiment are shown.

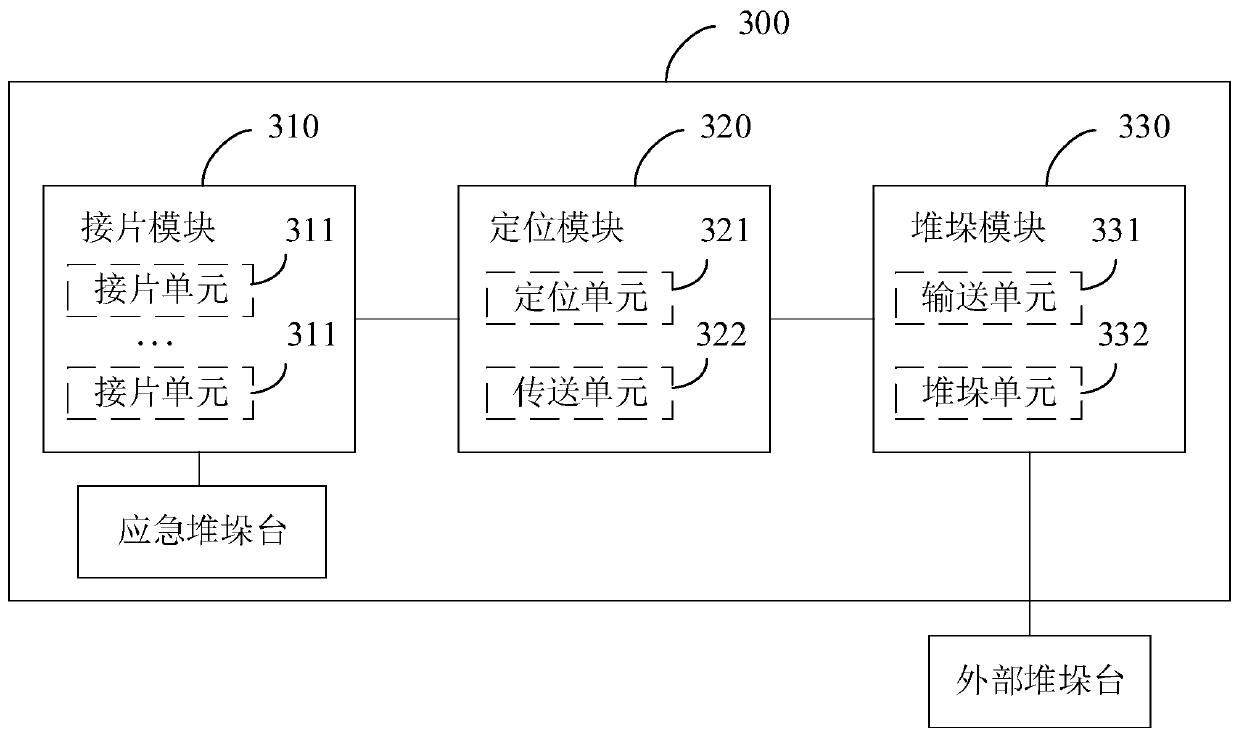

[0056] see figure 1 , the automatic stacking system includes: a control module 100 , a conveying roller table 200 and at least two sets of stacking devices 300 .

[0057]Wherein, the control module 100 is connected with the conveying roller table 200; the control module 100 classifies the materials on the conveying roller table 200 according to the data information of the materials, and conveys each type of material to the corresponding stacking device 300 through the conveying roller table 200 . Each group of stacking devices 300 receives the material conveyed by the conveying roller table 200, and obtains the status signal of the current material, and sends the status signal to the control module 100; then the control module stacks to each group according to the status signal The dev...

Embodiment 2

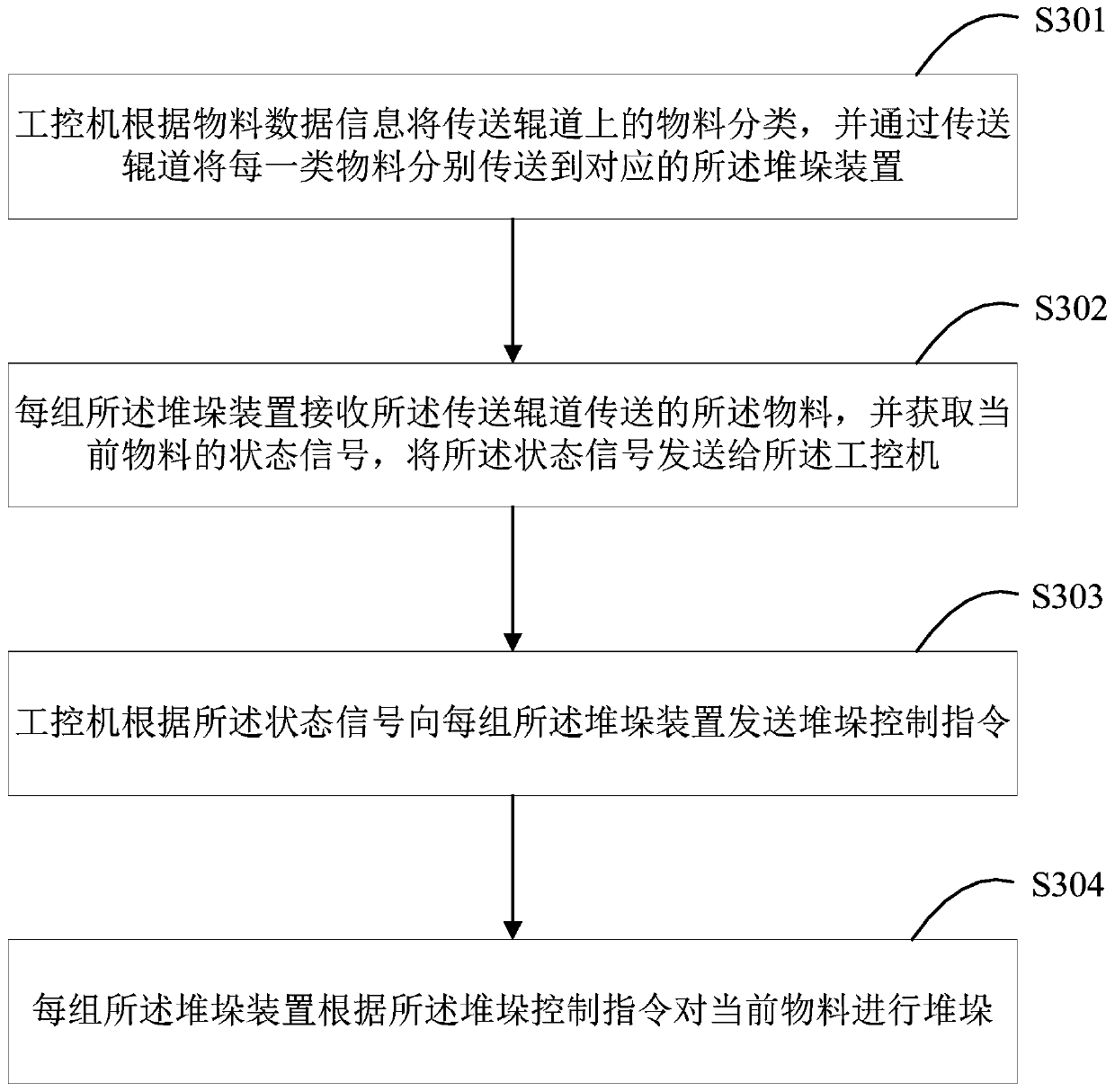

[0110] Corresponding to the automatic stacking system in Embodiment 1, this embodiment provides an automatic stacking method, which is suitable for an automatic stacking system including a control module, a conveying roller table and at least two sets of stacking devices. see image 3 , provides a schematic diagram of the implementation process of an embodiment of the automatic stacking method, detailed as follows:

[0111] S301, the control module classifies the materials on the conveying roller table according to the material data information, and conveys each type of material to the corresponding stacking device through the conveying roller table.

[0112] Optionally, when there is only one type of material, the control module can control at least one group of stacking devices in at least two groups of stacking devices to stack materials according to user input, or can control at least one group of stacking devices in at least two groups of stacking devices according to use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com