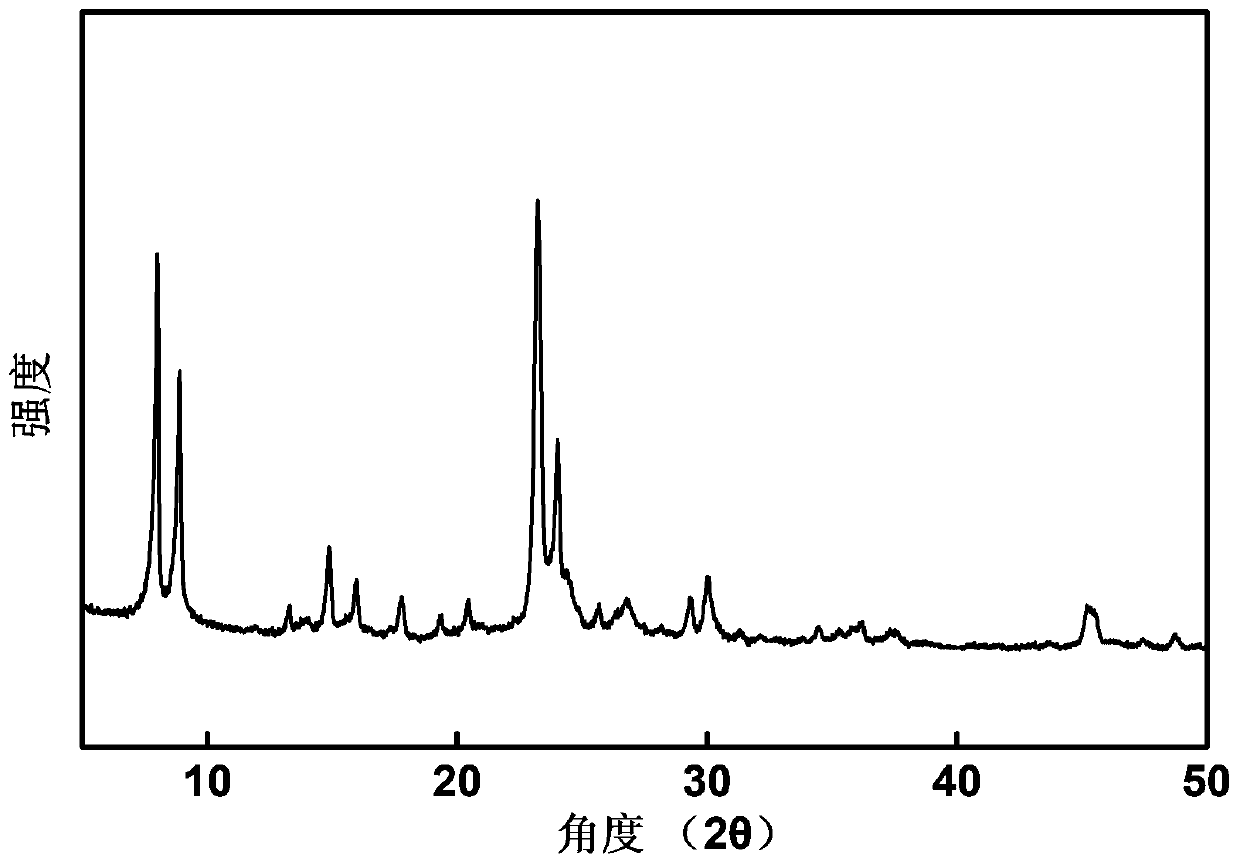

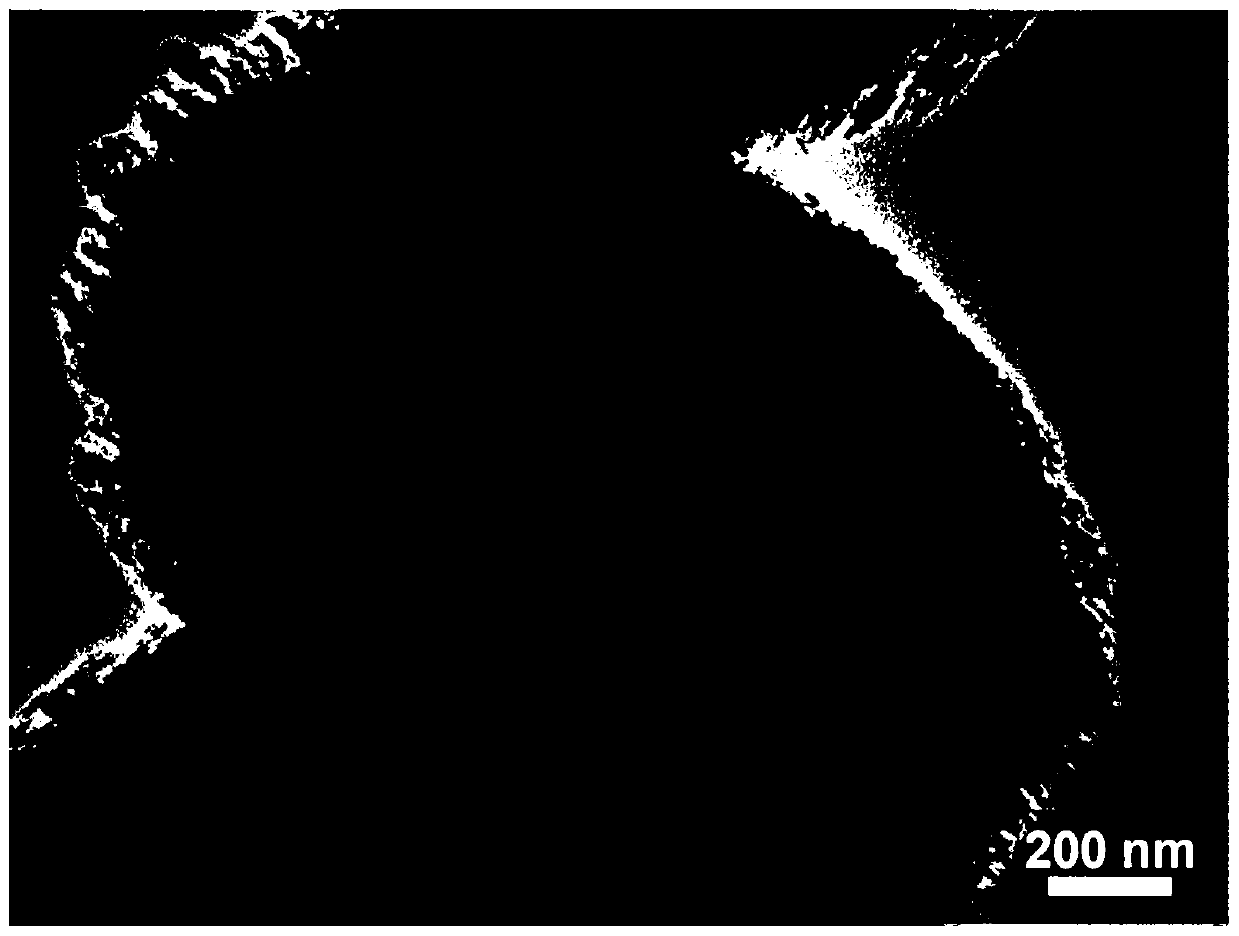

Bimetallic MEL molecular sieve as well as preparation method and application thereof

A bimetallic and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of active and selective catalyst design and application, and achieve excellent catalytic performance, activity and selectivity Good, the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present embodiment carries out the preparation of bimetallic MEL molecular sieve, comprises the following steps:

[0047] Weigh 16.22g of tetrabutylammonium hydroxide and place it in deionized water to obtain a 40wt% aqueous solution, slowly add 21.47g of tetrabutylammonium hydroxide under magnetic stirring, and add 38.87mL of deionized water after the solution is clarified to obtain a mixed solution; magnetic stirring After 6 hours, add 0.12 g of ferric citrate and 0.54 g of copper acetylacetonate to obtain the first product; after 8 hours of magnetic stirring, place the first product in a reaction kettle for hydrothermal crystallization at 170° C. for 72 hours; filter the crystallized product and use Repeated washing with deionized water and drying in a drying oven at 100°C for 12 hours to obtain the second product, namely all-silicon P-MEL@Cu / Fe molecular sieve; 0.015mol / L aluminum isopropoxide and 0.1mol / L tetrabutyl hydroxide were oxidized Ammonium is prepared ...

Embodiment 2

[0055] The present embodiment carries out the preparation of bimetallic MEL molecular sieve, comprises the following steps:

[0056] Weigh 16.22g of tetrabutylammonium hydroxide and place it in deionized water to obtain a 40wt% aqueous solution, slowly add 21.47g of tetrabutylammonium hydroxide under magnetic stirring, and add 38.87mL of deionized water after the solution is clarified to obtain a mixed solution; magnetic stirring After 6 hours, add 0.25 g of ferric citrate and 0.54 g of copper acetylacetonate to obtain the first product; after 8 hours of magnetic stirring, place the first product in a reaction kettle for hydrothermal crystallization at 170° C. for 72 hours; filter the crystallized product and use Repeated washing with deionized water and drying in a drying oven at 100°C for 12 hours to obtain the second product, namely all-silicon P-MEL@Cu / Fe molecular sieve; 0.015mol / L aluminum isopropoxide and 0.1mol / L tetrabutyl hydroxide were oxidized Ammonium is prepared ...

Embodiment 4

[0067] In this example, the catalytic performances of the bimetallic MEL molecular sieves of Examples 1-2, Fe metal MEL molecular sieves of Comparative Example 1 and bimetallic MEL molecular sieves of Comparative Example 2 were evaluated by Friedel-Crafts alkylation of trimethylbenzene and benzyl alcohol.

[0068] A three-neck round bottom flask equipped with a reflux condenser was tested for catalytic performance in a temperature-controlled oil bath. First, 40 mmol of mesitylene and 0.1 g of MEL molecular sieves were mixed and kept stirring at 100 ° C for 0.5 h, and then added 4mmol benzyl alcohol, with the addition time as the initial reaction time. Finally, the reaction solution was taken out to analyze the product by gas chromatography. The conversion ratio of benzyl alcohol and the selectivity of alkylation product are shown in Table 1, and Table 1 shows that the bimetallic MEL molecular sieve catalyst activity of the present invention and selectivity are better than only...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com