Catalytic method for methane dry reforming

A methane dry reforming, methane technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of limited conversion rate and product selectivity of methane and carbon dioxide , side reaction products and other problems, to achieve excellent thermal stability, improve selectivity, improve selectivity and yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

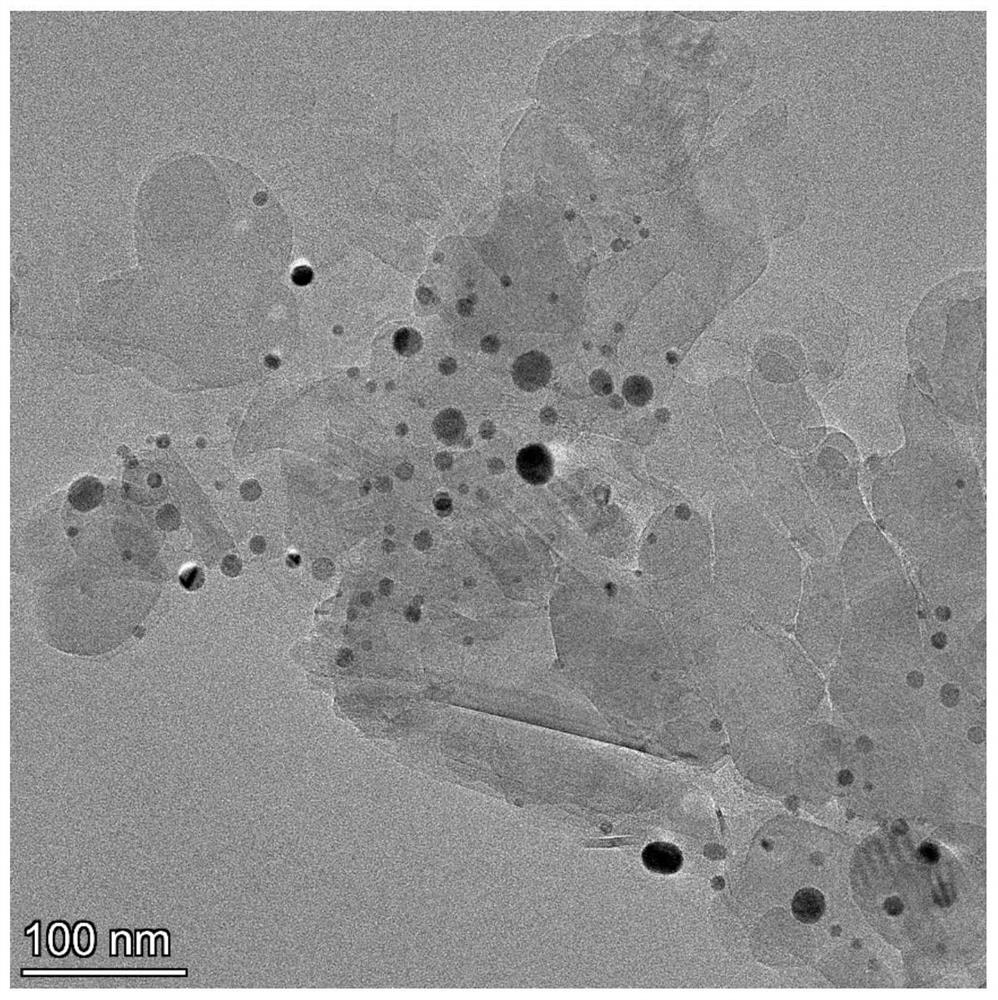

[0031] The preparation method of described nickel-based boron nitride catalyst comprises the steps:

[0032] 1) putting boron nitride into isopropanol for ultrasonication, and then drying it to obtain a thin boron nitride carrier;

[0033] 2) mixing the metallic nickel salt solution with the dried flake boron nitride, and then drying it to obtain the dried mixture;

[0034] 3) Calcining the dried mixture in air to obtain the nickel-based boron nitride catalyst.

[0035] In step 1), the mixing method is to put boron nitride in the isopropanol solution; the mass volume ratio of the boron nitride to the isopropanol solution is 1: (50-1000), and the ultrasonic time is 12h-36h,

[0036] In step 2), the mixing method is to drop the metal nickel salt solution onto the boron nitride carrier; the mass ratio of nickel nitrate and boron nitride carrier in the metal nickel salt solution is (0.002-0.04): 1 , the drying temperature is 80°C-110°C, and the drying time is 8-24h;

[0037] I...

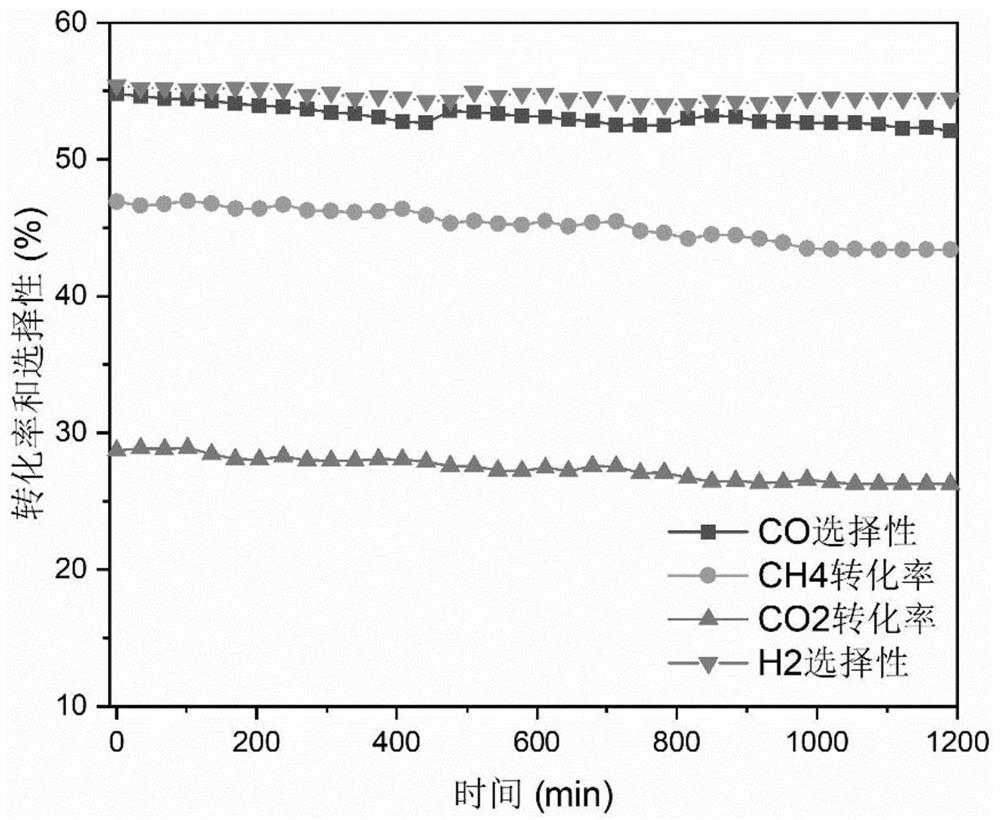

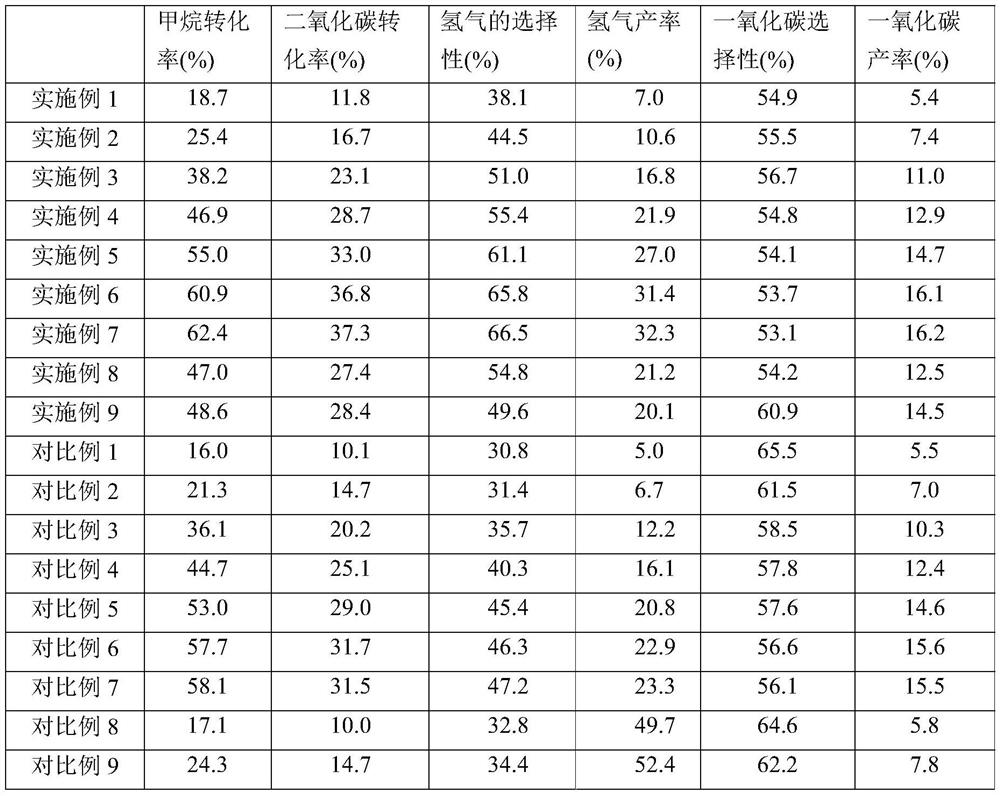

Embodiment 1

[0040] Mix methane, carbon dioxide and argon to obtain a mixed raw material gas (the volume ratio of methane, carbon dioxide and argon in the mixed raw material gas is 1:1:1), and mix the mixed raw material gas for 720h -1The volume space velocity passes into DBD low-temperature plasma reactor (the discharge area of described DBD low-temperature plasma reactor is equipped with 1g nickel-based boron nitride catalyst, and the active component of described nickel-base boron nitride catalyst is metallic nickel, The carrier is boron nitride, and the metal nickel in the nickel-based boron nitride catalyst is 4% by mass in the catalyst) for catalytic reaction, the reaction temperature is 25°C, the reaction pressure is normal pressure, and the mixing The feed gas passes through the dielectric barrier discharge region at a flow rate of 60ml / min. The power of the DBD low-temperature plasma reactor is 21.8w, and the discharge frequency is 7.4kHz to prepare the product synthesis gas (hyd...

Embodiment 2

[0048] Mix methane, carbon dioxide and argon to obtain a mixed raw material gas (the volume ratio of methane, carbon dioxide and argon in the mixed raw material gas is 1:1:1), and mix the mixed raw material gas for 720h -1 The volume space velocity passes into DBD low-temperature plasma reactor (the discharge area of described DBD low-temperature plasma reactor is equipped with 1g nickel-based boron nitride catalyst, and the active component of described nickel-base boron nitride catalyst is metallic nickel, The carrier is boron nitride, and the nickel-based boron nitride catalyst (heavy metal nickel in the catalyst is 4% by mass) carries out a catalytic reaction, the reaction temperature is 35° C., and the reaction pressure is 0.1 MPa. The reaction raw material The residence time of gas in the dielectric barrier discharge area is 8.5s, the power of the DBD low-temperature plasma reactor is 29.4w, the discharge frequency is 7.4kHz, and the prepared catalytic products synthesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com