Microencapsulated catalyst

A technology of microencapsulation and catalyst, applied in microcapsule preparation, catalyst protection, physical/chemical process catalyst, etc., can solve problems such as the difficulty of catalytic materials, and achieve the effect of reducing deactivation paths, prolonging service life, and being easy to handle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0086] The encapsulation of embodiment 1-1Kg scale nickel-aluminum alloy

[0087] For a theoretical 1.33 kg batch, the following raw materials are required, which yield approximately 2.8 kg of beads under 50% wet water conditions.

[0088] raw material

the form

weight

volume

Stabilizer Reax TM 100M

840g

n / a

Surfactant Tergitol TM XD 100%

solid

105g

n / a

Surfactant Polyvinyl Alcohol 100%

solid

420g

n / a

Deionized water for aqueous phase

the liquid

n / a

9135ml

Chloroform stabilized with pentene

the liquid

2880g

2009ml

Polymethylpolyphenylisocyanate

the liquid

1350g

1125ml

DispersantSolsperse TM 32000

solid

27.34g

n / a

nickel-aluminum alloy

solid

270g

n / a

deionized water for decantation

the liquid

20000g

20000ml

Deionized water for washing

the liq...

Embodiment 2-250

[0105] Preparation of activated Ni EnCat under the scale of embodiment 2-250g

[0106] 1 L of deionized water was added to a 2 L screw cap jar, followed by 50 g of sodium hydroxide pellets in aliquots every 5 minutes while stirring, for a total of 240 g. Once all the sodium hydroxide had been added, the solution was cooled to room temperature and sparged with nitrogen continuously.

[0107] To a device equipped with a mechanical stirrer, thermocouple, condenser and N 2 Add 400ml of the caustic alkali solution prepared above into the 3L jacketed-flange reactor at the inlet, and inject nitrogen into the reactor. Weigh 200 g of wet water Ni EnCat beads and add to the reactor in 50 g portions while stirring. Rapid bubbling was observed, then the resulting hydrogen was vented through a dehydrator. After 10 minutes, the reaction had subsided, and then another 50 g of beads were added to the reactor. This process was repeated until all beads had been added to the reactor. The re...

Embodiment 3-4

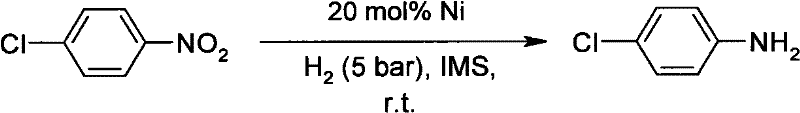

[0110] The reduction of embodiment 3-4-chloronitrobenzene

[0111]

[0112] Activated Ni EnCat (0.26 g, wet water, 20 mol% Ni on substrate) was washed three times with IMS to remove water and added to IMS (4 ml) containing 4-chloronitrobenzene (0.157 g, 1 mmol) solution in a pressure vessel. The vessel was sealed and flushed twice with hydrogen, then pressurized to 5-6 bar with hydrogen and the contents stirred magnetically at room temperature. The progress of the reaction was analyzed by GCMS. After 24 hours, the hydrogen was vented and the Ni EnCat beads were removed by filtration. The filtrate was concentrated on a rotary evaporator to give 4-chloroaniline (0.12 g, 95%). GCMS purity 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com