Horseradish peroxidase @ MOF composite catalyst and preparation method thereof

A technology of horseradish peroxidase and composite catalyst, which is applied to biochemical equipment and methods, oxidoreductases, enzymes and other directions, can solve the problems of high environmental requirements, secondary pollution, low stability and the like, and achieves a simple preparation method. , easy recovery, mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation of horseradish peroxidase@FeBTC composite catalyst

[0036] First, dissolve 0.4167g of dimethyl sulfoxide in 10mL of deionized water, add 0.003g of phthalic anhydride, and mix well; take 0.004g of horseradish catalase and dissolve it in 4mL of deionized water, add 0.3mL of the above Diformic anhydride solution was stirred at 4 °C for 1 h. Centrifuge and wash with water to remove excess modifier. Then, 0.002 g of the pre-prepared FeBTC shell MOF material was added to 4 mL of deionized water to make it uniformly dispersed by ultrasound, and then the modified horseradish peroxidase was added therein, and stirred at 4 °C for 2 h. After the reaction was completed, it was centrifuged and washed three times with deionized water, and then dried at 20° C. to obtain the horseradish peroxidase@FeBTC composite catalyst.

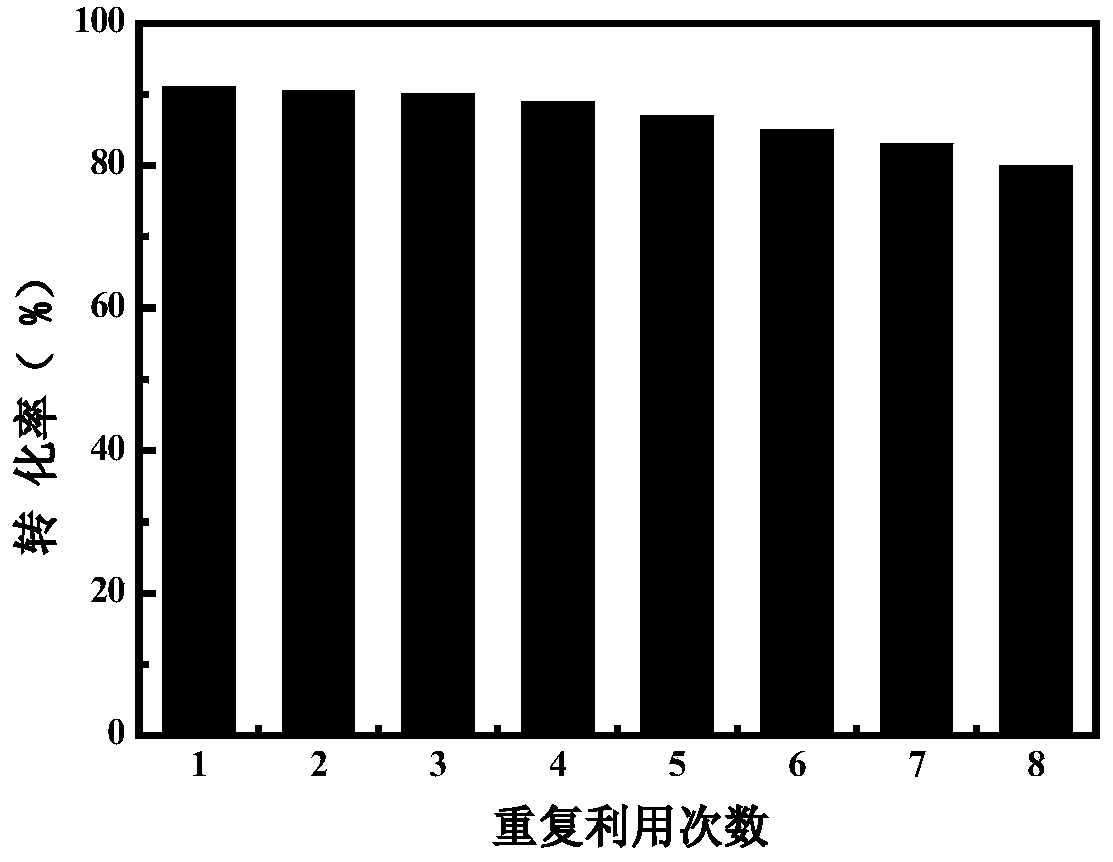

[0037]The horseradish peroxidase@FeBTC composite catalyst was tested for o-phenylenediamine catalysis, and the conversion rate of o-ph...

Embodiment 2

[0038] Example 2: Preparation of horseradish peroxidase@CuBTC composite catalyst

[0039] First, dissolve 0.4167g of dimethyl sulfoxide in 10mL of deionized water, add 0.003g of phthalic anhydride, and mix well; take 0.004g of horseradish catalase and dissolve it in 4mL of deionized water, add 0.3mL of the above Diformic anhydride solution was stirred at 4 °C for 1 h. Centrifuge and wash with water to remove excess modifier. Then, 0.002 g of the pre-prepared CuBTC shell MOF material was added to 4 mL of deionized water to make it uniformly dispersed by ultrasonic, and then the modified horseradish peroxidase was added, and stirred at 4 °C for 2 h. After the reaction was completed, it was centrifuged and washed three times with deionized water, and then dried at 20° C. to obtain the horseradish peroxidase@CuBTC composite catalyst.

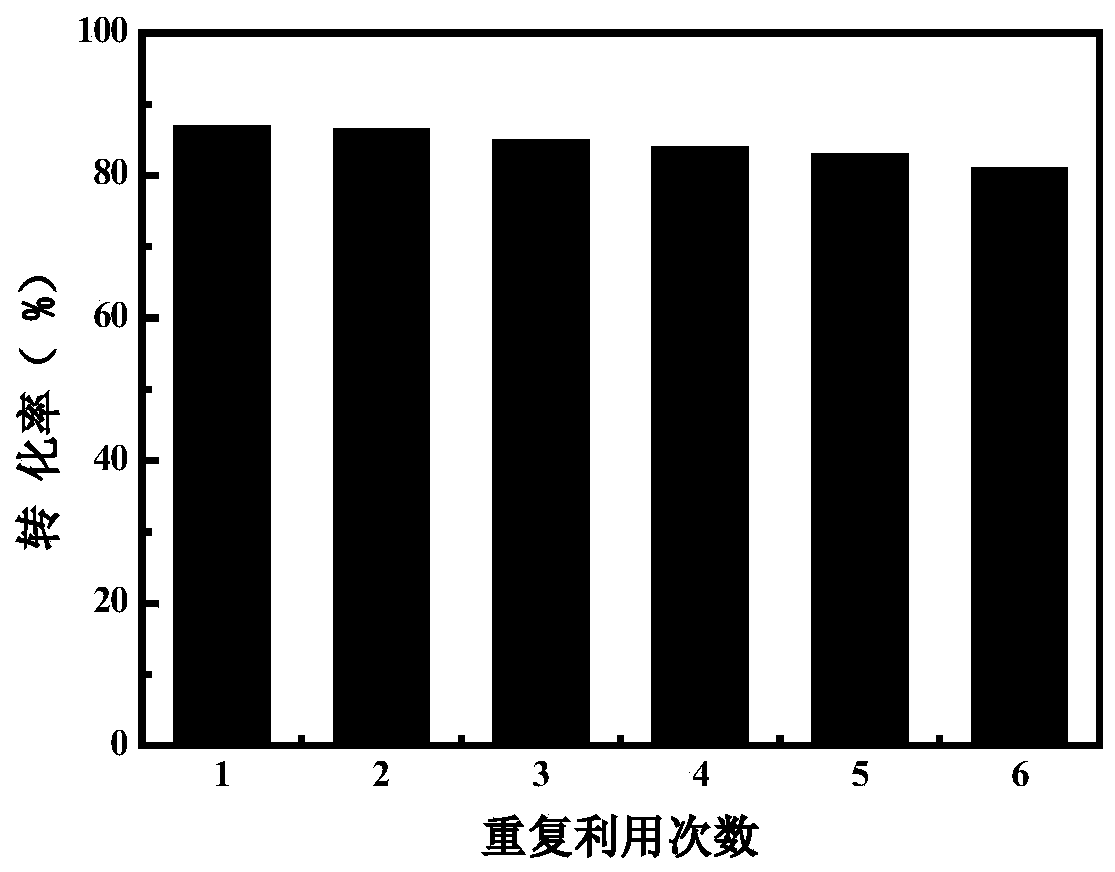

[0040] The horseradish peroxidase@CuBTC composite catalyst was tested for o-phenylenediamine catalysis, and the conversion rate of o-phenylenedia...

Embodiment 3

[0041] Embodiment 3: Preparation of horseradish peroxidase@CuBDC composite catalyst

[0042] First, dissolve 0.4167g of dimethyl sulfoxide in 10mL of deionized water, add 0.003g of phthalic anhydride, and mix well; take 0.004g of horseradish catalase and dissolve it in 4mL of deionized water, add 0.3mL of the above Diformic anhydride solution was stirred at 4 °C for 1 h. Centrifuge and wash with water to remove excess modifier. Then, 0.002 g of the pre-prepared CuBDC shell MOF material was added to 4 mL of deionized water to make it uniformly dispersed by ultrasonic, and then the modified horseradish peroxidase was added, and stirred at 4 °C for 2 h. After the reaction was completed, it was centrifuged and washed three times with deionized water, and then dried at 20° C. to obtain the horseradish peroxidase@CuBDC composite catalyst.

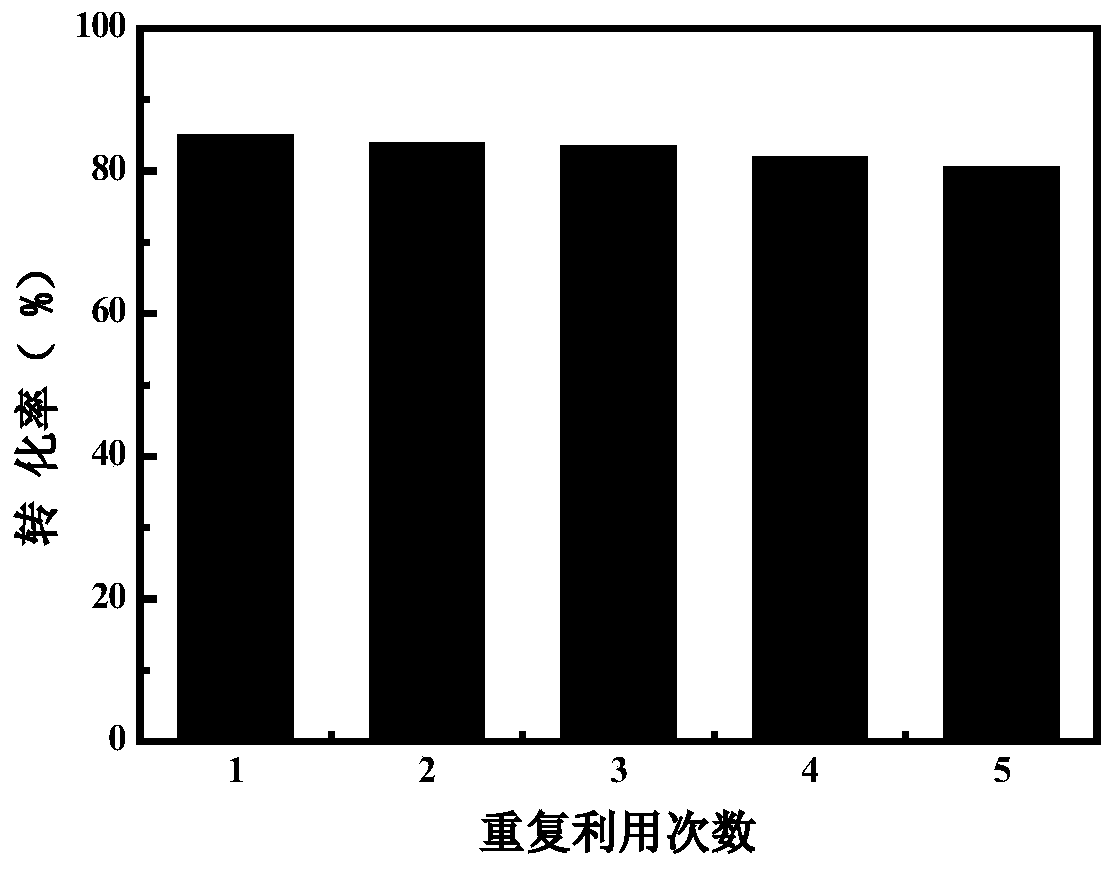

[0043] The horseradish peroxidase@CuBDC composite catalyst was tested and analyzed for o-phenylenediamine catalysis experiments. The conversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com