Preparation device and preparation method of hydrophobic slow-release organic-inorganic compound fertilizer

A technology of compound fertilizer and preparation device, which is applied to fertilization device, fertilizer mixture, ammonium orthophosphate fertilizer and other directions, can solve the problems of low solubility, improve the quality of chemical fertilizer, slow decomposition speed, etc. release effect, the effect of slow decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

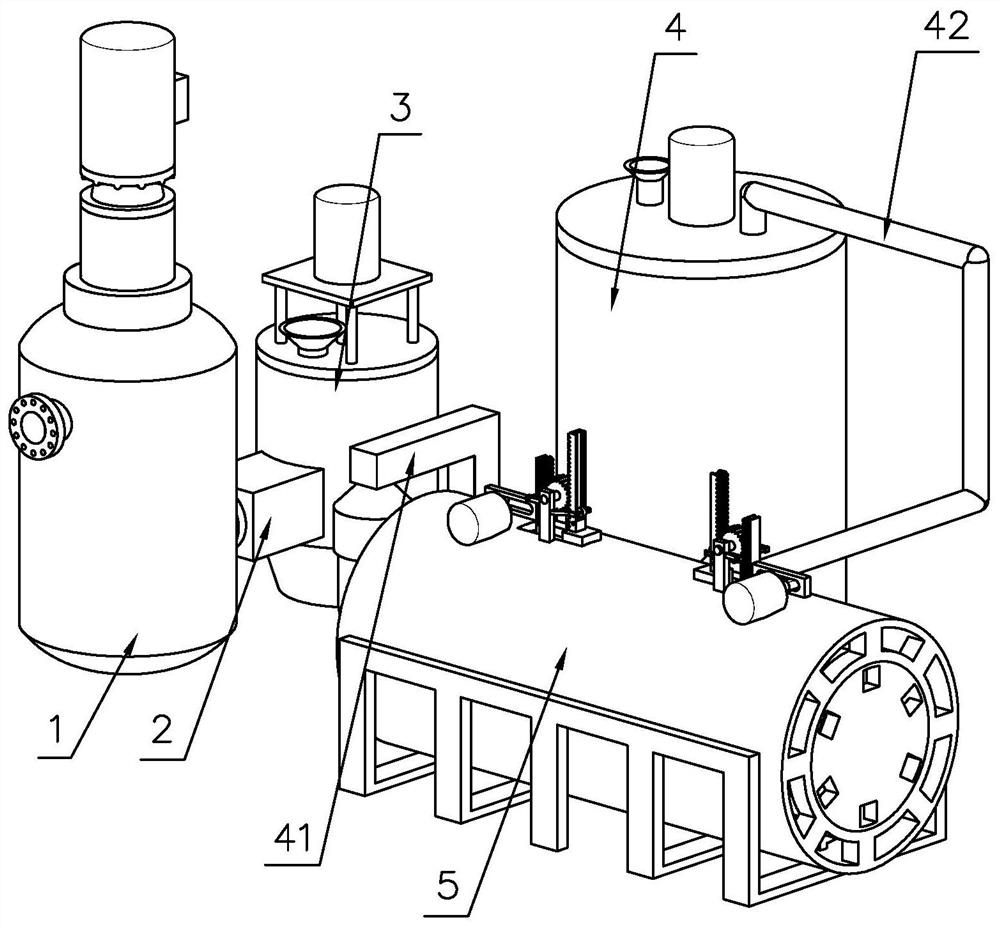

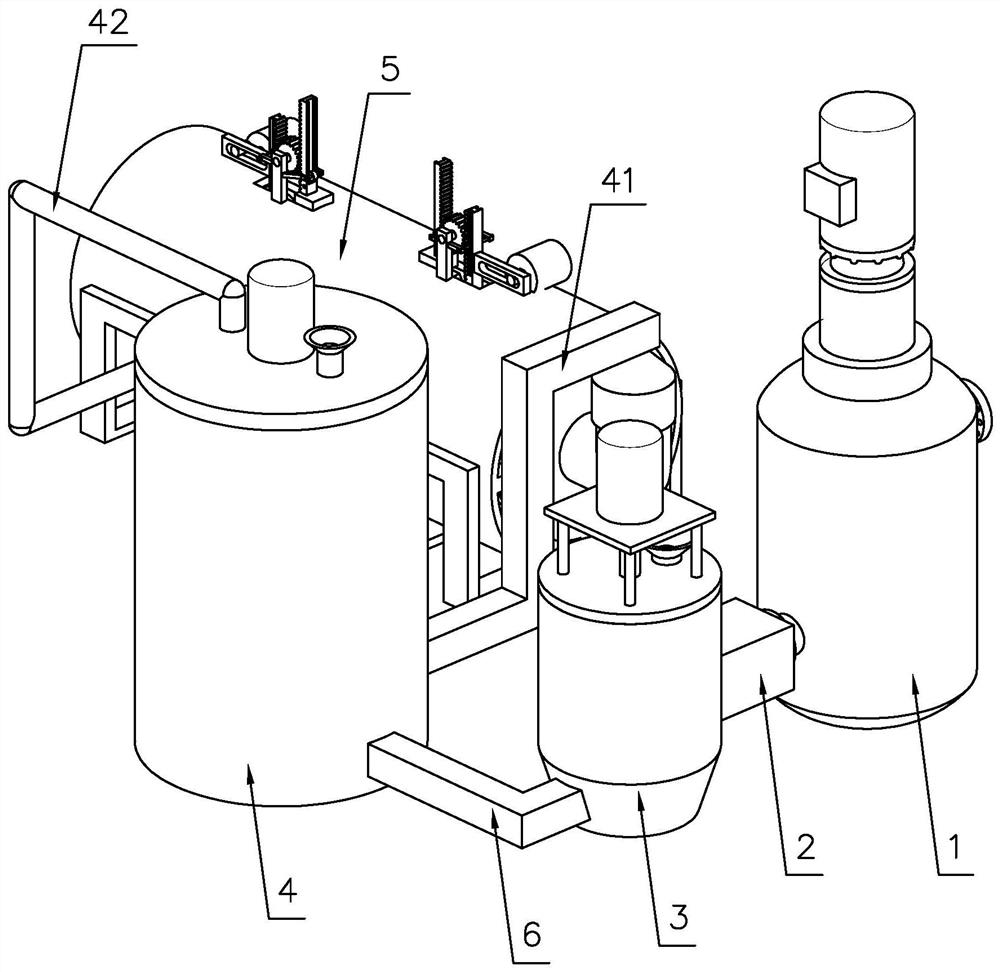

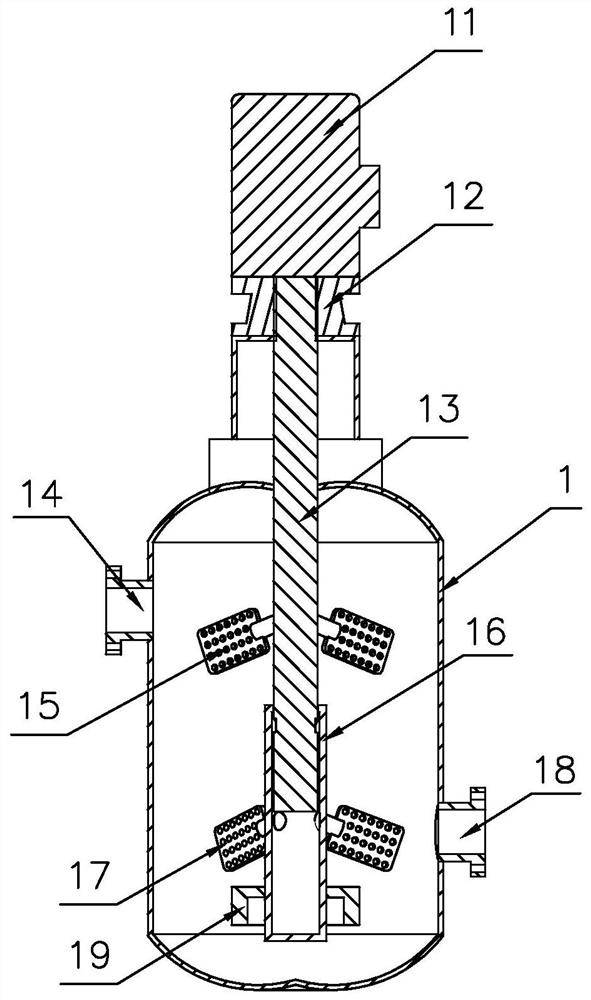

Method used

Image

Examples

Embodiment 1

[0034] A hydrophobic slow-release organic-inorganic compound fertilizer, including inorganic fertilizers, nitrogen fertilizers, phosphate fertilizers, potassium fertilizers, and medium and trace elements, molasses liquid, humic acid, activated by potassium hydroxide, sodium pyrophosphate, and formaldehyde under specific conditions, hydrophobic The sustained release agent is carnauba wax;

[0035] A method for preparing a hydrophobic slow-release organic-inorganic compound fertilizer, comprising the following steps:

[0036] Step 1: In parts by weight, add 150 parts of molasses liquid, 100 parts of humic acid, and 200 parts of water into the humic acid activation reaction kettle, add 10 parts of potassium hydroxide, 4 parts of sodium pyrophosphate, and 1 part of formaldehyde. Constant temperature at 80°C, stir and activate for 60 minutes to prepare activated humic acid slurry, pump the slurry to the compounding tank, add 200 parts of inorganic fertilizer raw materials into the ...

Embodiment 2

[0049] A method for preparing a hydrophobic slow-release organic-inorganic compound fertilizer, comprising the following steps:

[0050] Step 1: In parts by weight, add 170 parts of molasses liquid, 145 parts of humic acid, and 350 parts of water into the humic acid activation reaction kettle, add 14 parts of potassium hydroxide, 7 parts of sodium pyrophosphate, and 3 parts of formaldehyde. Constant temperature at 82°C, stirring and activation for 70 minutes to prepare activated humic acid slurry, pump the slurry to the compounding tank, add 800 parts of inorganic fertilizer raw materials into the compounding tank, add water appropriately according to the dissolution situation, fully stir and dissolve, and make The organic-inorganic compound fertilizer slurry is obtained and pumped to the slurry buffer tank for storage;

[0051] Step 2: In parts by weight, 30 parts of carnauba wax is put into a melting tank, heated to 75°C and fully stirred and melted to prepare a hydrophobic ...

Embodiment 3

[0056] A method for preparing a hydrophobic slow-release organic-inorganic compound fertilizer, comprising the following steps:

[0057] Step 1: In parts by weight, add 200 parts of molasses liquid, 200 parts of humic acid, and 500 parts of water into the humic acid activation reaction kettle, add 20 parts of potassium hydroxide, 10 parts of sodium pyrophosphate, and 5 parts of formaldehyde. Constant temperature at 85°C, stirring and activating for 90 minutes to prepare activated humic acid slurry, pump the slurry to the compounding tank, add 1500 parts of inorganic fertilizer raw materials into the compounding tank, add water appropriately according to the dissolution situation, fully stir and dissolve, and make The organic-inorganic compound fertilizer slurry is obtained and pumped to the slurry buffer tank for storage;

[0058] Step 2: In parts by weight, 50 parts of carnauba wax is put into a melting tank, heated to 80°C and fully stirred and melted to prepare a hydrophobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com