Treatment method of household garbage incineration fly ash

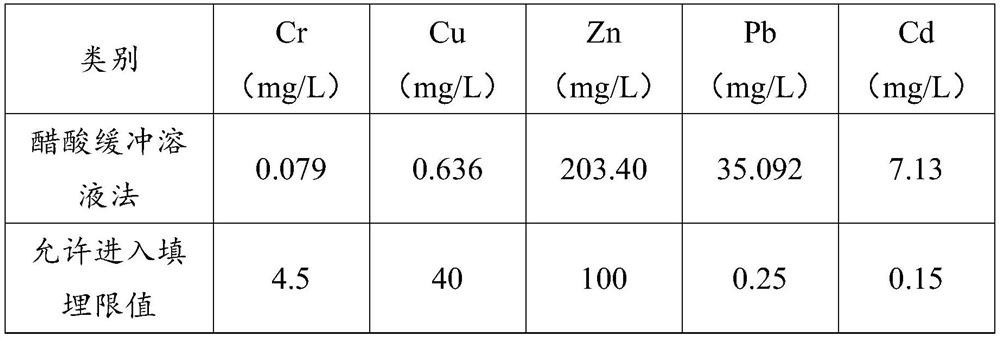

A technology of domestic waste incineration and treatment method, which is applied in the treatment field of domestic waste incineration fly ash, and can solve the problems of domestic waste incineration fly ash and danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

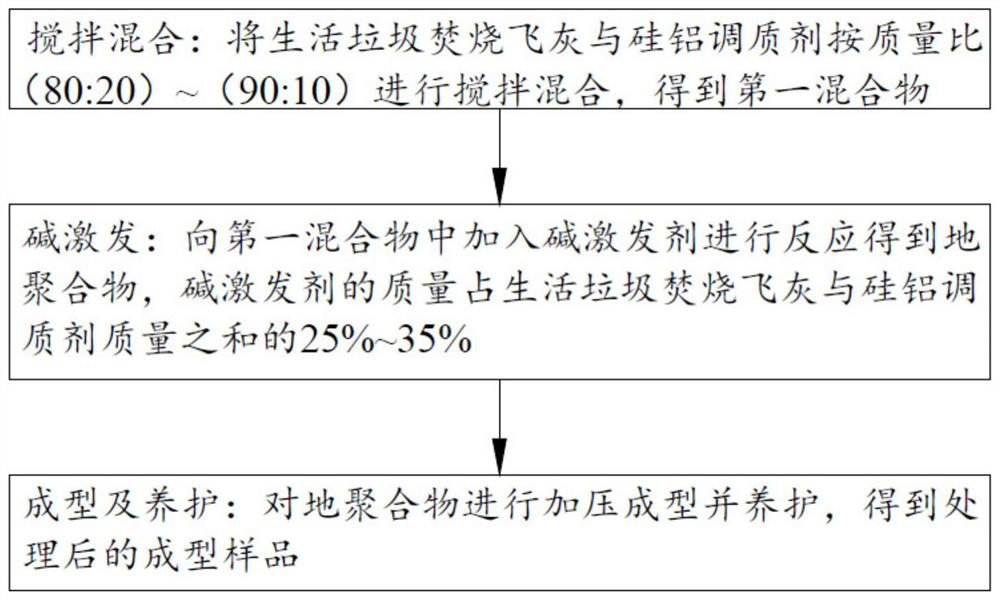

[0042] The present embodiment provides a processing method for domestic waste incineration fly ash, comprising the following steps:

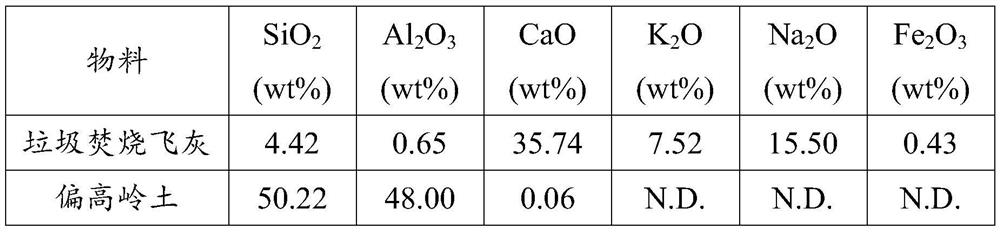

[0043] Stirring and mixing: Weigh 90 g of domestic waste incineration fly ash and 10 g of silicon-aluminum conditioner, and perform full grinding, stirring, and mixing to obtain the first mixture. Wherein, the mass ratio of the abrasive used for grinding to the sum of the domestic waste incineration fly ash and the silicon-aluminum conditioner is 2:1, the grinding speed is 300-400 rpm, and the grinding time is 30 minutes to obtain the first mixture. Among them, the silicon-aluminum conditioner is metakaolin.

[0044] Alkali excitation: 30 g of an alkali activator was added to the first mixture, and the stirring was continued for 30 minutes to obtain a geopolymer. Among them, the alkali activator is prepared from sodium hydroxide and water glass solution (mass ratio: 12:100).

[0045] Molding and curing: Put the geopolymer into a stainless stee...

Embodiment 2

[0047] The present embodiment provides a processing method for domestic waste incineration fly ash, comprising the following steps:

[0048] Stirring and mixing: Weighing 90 g of domestic waste incineration fly ash and 10 g of metakaolin, fully grinding, stirring, and mixing to obtain the first mixture. Wherein, the mass ratio of the abrasive used for grinding to the sum of the domestic waste incineration fly ash and the silicon-aluminum conditioner is 2:1, the grinding speed is 300-400 rpm, and the grinding time is 30 minutes to obtain the first mixture. Among them, the silicon-aluminum conditioner is metakaolin.

[0049] Alkali excitation: 25 g of an alkali activator was added to the first mixture, and the stirring was continued for 30 minutes to obtain a geopolymer. Among them, the alkali activator is prepared from sodium hydroxide and water glass solution (mass ratio: 12:100).

[0050] Molding and maintenance: Put the geopolymer into a stainless steel mold, place it on a...

Embodiment 3

[0052] The present embodiment provides a processing method for domestic waste incineration fly ash, comprising the following steps:

[0053] Stirring and mixing: Weighing 90 g of domestic waste incineration fly ash and 10 g of metakaolin, fully grinding, stirring, and mixing to obtain the first mixture. Wherein, the mass ratio of the abrasive used for grinding to the sum of the domestic waste incineration fly ash and the silicon-aluminum conditioner is 2:1, the grinding speed is 300-400 rpm, and the grinding time is 30 minutes to obtain the first mixture. Among them, the silicon-aluminum conditioner is metakaolin.

[0054] Alkali excitation: 25 g of an alkali activator was added to the first mixture, and the stirring was continued for 30 minutes to obtain a geopolymer. Among them, the alkali activator is prepared from sodium hydroxide and water glass solution (mass ratio: 12:100).

[0055] Molding and maintenance: Put the geopolymer into a stainless steel mold, place it on a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com