Hygroscopic antibacterial hydrocolloid dressing and preparation method thereof

A hydrocolloid and preparation technology, applied in medical science, bandages, etc., can solve the problems of skin barrier loss of integrity, fluid leakage, etc., and achieve the effects of improving mechanical properties, reducing cold flow, and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

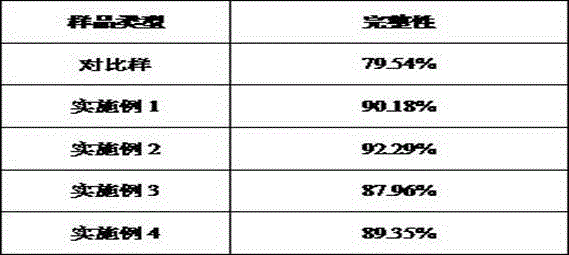

Examples

Embodiment 1

[0025] A preparation method of a hygroscopic antibacterial hydrocolloid dressing, the specific preparation process steps of the preparation method are:

[0026] (1) Ingredients: 10 parts by weight of styrene-isoprene-styrene block copolymer elastomer, 5 parts of vitamin C antioxidant, 50 parts of water-soluble hydrocolloid, 20 parts of Dioctyl dioate plasticizer, 10 parts of tackifier and 5 parts of liquid paraffin softener are mixed and added to the extruder in turn; the water-soluble hydrocolloid is carboxymethyl chitosan quaternary The mixture of ammonium salt, sodium alginate, sodium carboxymethyl cellulose, grafted acrylamide and cross-linked hydroxyethyl cellulose grafted acrylamide polymer in a mass ratio of 1:1:1:1:1, said The tackifier is a mixture of disproportionated rosin ester and terpene resin in a mass ratio of 1:1;

[0027] (2) Extrusion: heat and extrude the material prepared in step (1) in the extruder. The extrusion conditions are: the heating range of the ...

Embodiment 2

[0032] A preparation method of a hygroscopic antibacterial hydrocolloid dressing, the specific preparation process steps of the preparation method are:

[0033] (1) Ingredients: 30 parts by weight of polyurethane rubber elastomer, 1 part of vitamin C antioxidant, 10 parts of water-soluble hydrocolloid, 30 parts of tributyl citrate plasticizer, 25 parts of C9 Petroleum resin tackifier and 4 parts of softener are mixed and added to the extruder in turn; the water-soluble hydrocolloids are carboxymethyl chitosan quaternary ammonium salt, sodium alginate, carboxymethyl cellulose A mixture of sodium, grafted acrylamide, and cross-linked hydroxyethyl cellulose grafted acrylamide polymer in a mass ratio of 4:4:2:1:1, and the softener is vegetable oil and white vaseline in a mass ratio of 2 : a mixture of 1;

[0034] (2) Extrusion: heat and extrude the material prepared in step (1) in the extruder. The extrusion conditions are: the heating range of the extrusion area is 150°C, the he...

Embodiment 3

[0039] A preparation method of a hygroscopic antibacterial hydrocolloid dressing, the specific preparation process steps of the preparation method are:

[0040] (1) Ingredients: 15 parts by weight of polyacrylate elastomer, 10 parts of vitamin C antioxidant, 30 parts of water-soluble hydrocolloid, 5 parts of polyisobutyl ester plasticizer, 40 parts of terpene The olefin resin tackifier is mixed and added to the extruder in turn; the water-soluble hydrocolloid is carboxymethyl chitosan quaternary ammonium salt, sodium alginate, sodium carboxymethyl cellulose, grafted acrylamide , a mixture of cross-linked hydroxyethyl cellulose grafted acrylamide polymer in a mass ratio of 2:2:1:1:1;

[0041] (2) Extrusion: heat and extrude the material prepared in step (1) in the extruder. The extrusion conditions are: the heating range of the extrusion area is 120°C, the head temperature is 110°C, and the main engine speed is 50rpm. The feeding speed is 20rpm, and it becomes a block or strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com