ZIF@TU-POP composite catalyst, and preparation method and application thereof

A composite catalyst and reaction technology, applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of expensive metal catalysts, secondary pollution, and easy poisoning of catalysts and other issues, to achieve the effect of improving reusability, easy recycling, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 Preparation of ZIF shell material

[0028] Preparation of ZIF-8: Zn(NO 3 ) 2 ·6H 2 O 1.68g was dissolved in 80ml of methanol to obtain solution A, 3.7g of 2-methylimidazole was dissolved in 80ml of methanol to obtain solution B, solution A and solution B were mixed and stirred for 24h, filtered and washed with methanol, and vacuum-dried at 60°C for 12h Get ZIF-8.

[0029] Preparation of ZIF-67: Co(NO 3 ) 2 ·6H 2 O 1.69g was dissolved in 80ml of methanol to obtain solution A, 3.7g of 2-methylimidazole was dissolved in 80ml of methanol to obtain solution B, solution A and solution B were mixed and stirred for 24 hours, filtered and vacuum-dried to obtain ZIF-67.

Embodiment 2

[0030] Example 2 ZIF-8@TU-POP composite catalyst

[0031] 1. Synthetic route of ZIF-8@TU-POP composite catalyst

[0032]

[0033] 2. Preparation of ZIF-8@TU-POP composite catalyst

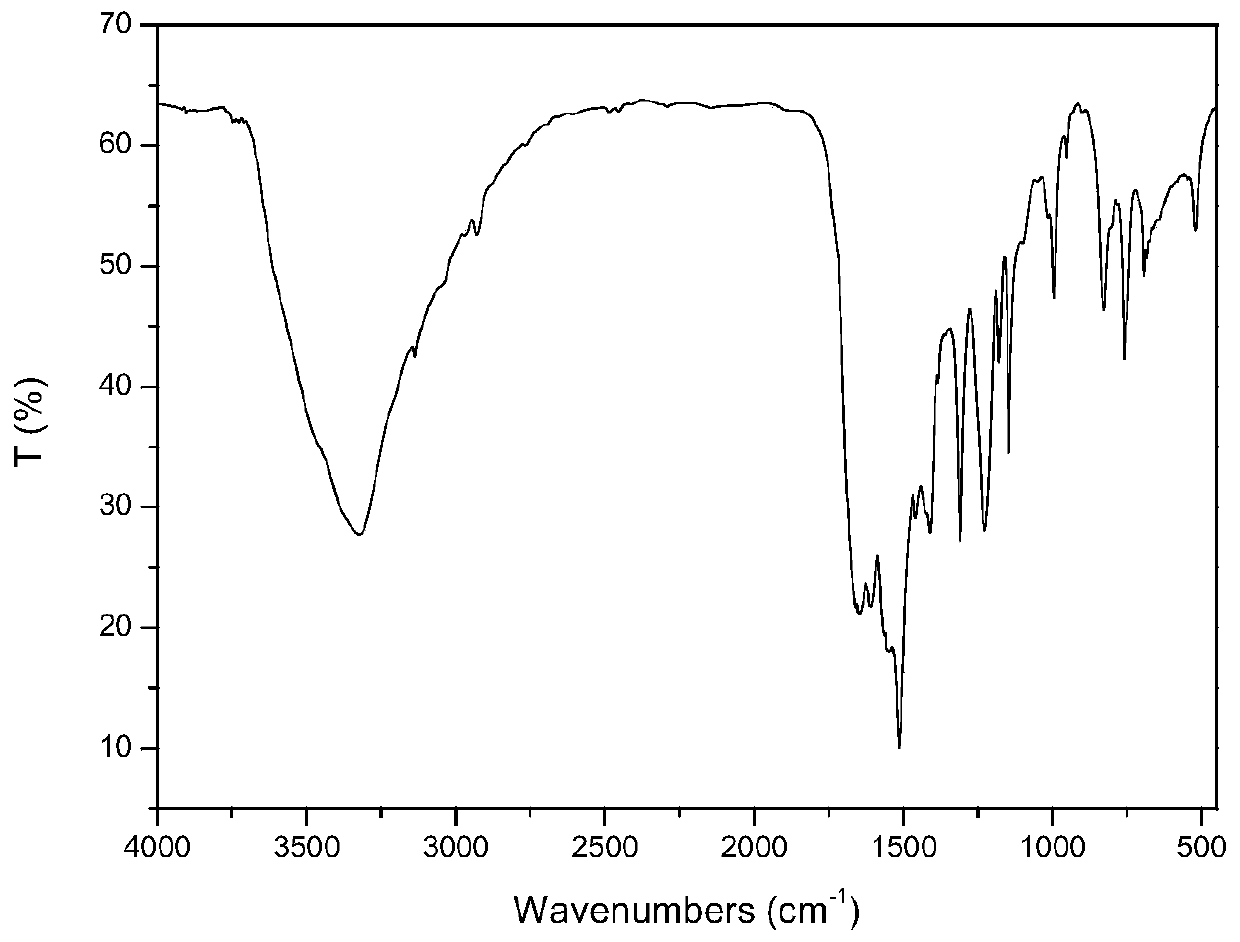

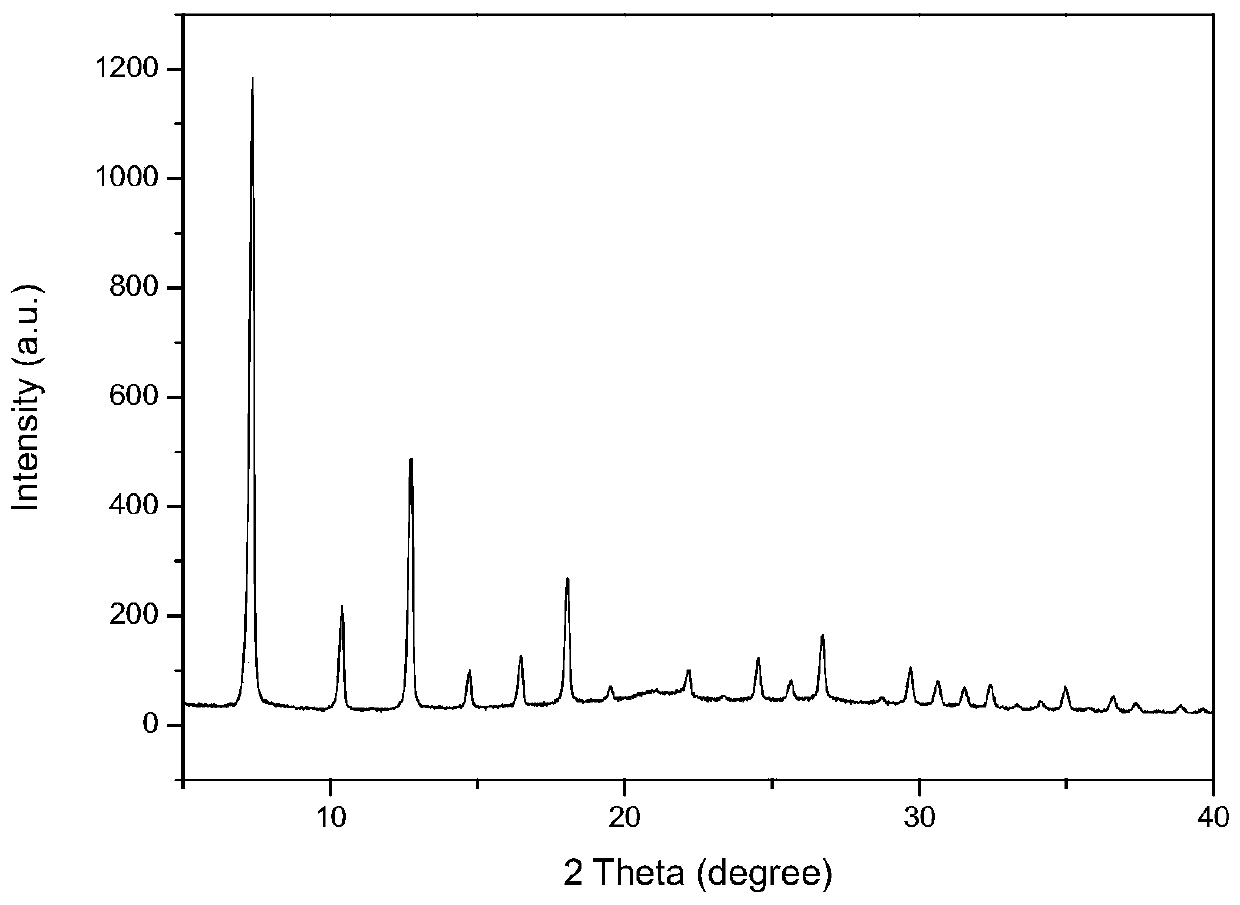

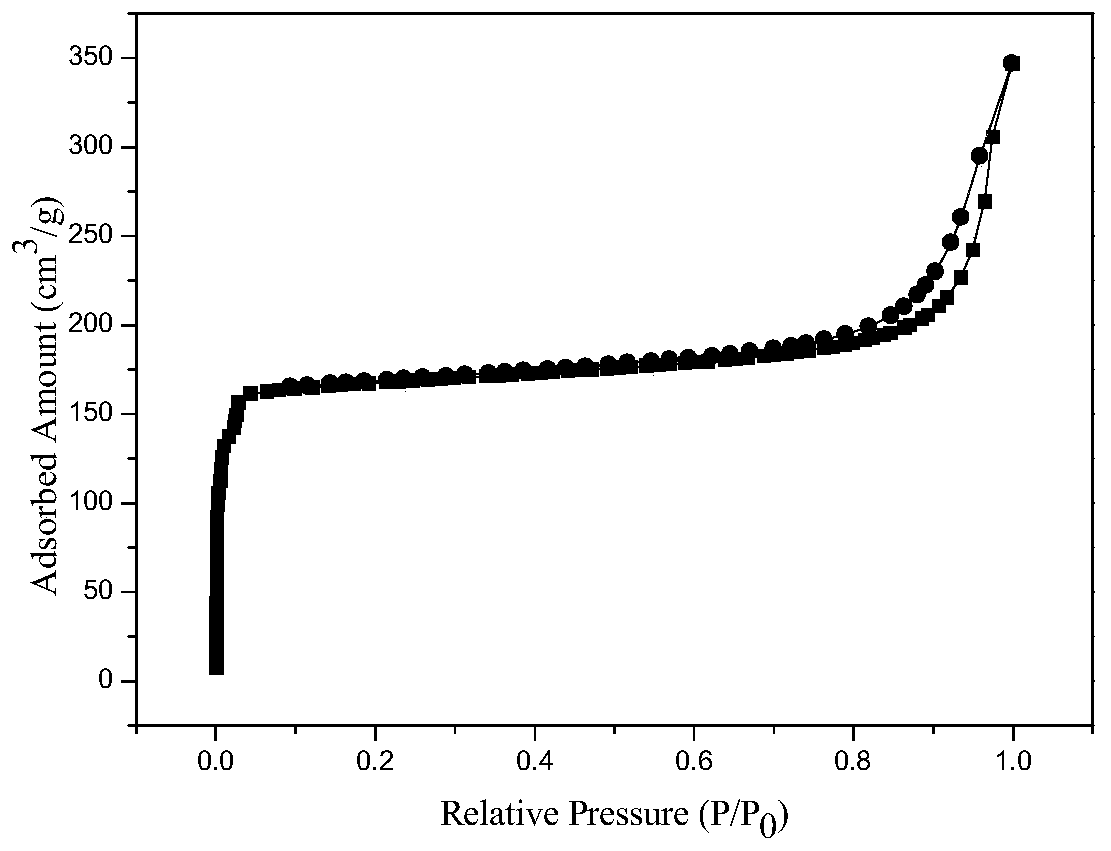

[0034] Add 3 g of urea, 2 ml of 39% sodium bisulfite solution and 2 ml of acetic acid into 50 ml of deionized water containing 4 g of p-phenylenediamine, and stir the mixture at 90° C. for 24 h, then filter and wash with a large amount of hot water, and then vacuum Drying gives the product 1,3-bis(4-aminophenyl)urea. Add 1g of 1,3-bis(4-aminophenyl)urea, 1.5g of cyanuric chloride, and 500mg of ZIF-8 into 10ml of dry dimethyl sulfoxide, keep the reaction temperature at 15°C, and add N , N-diisopropylethylamine 2ml, stirred for 24 hours, after the reaction was completed, the crude product was added to ice to form a solid, which was then filtered and washed with dichloromethane, tetrahydrofuran, and ethyl acetate to obtain ZIF-8@TU - POP composite catalyst. And did FT-IR on the catalyst ( figu...

Embodiment 3

[0039] Example 3 ZIF-67@TU-POP composite catalyst

[0040] 1. Synthetic route of ZIF-67@TU-POP composite catalyst

[0041]

[0042]2. Preparation of ZIF-67@TU-POP composite catalyst

[0043] Add 3 g of urea, 2 ml of 39% sodium bisulfite solution and 2 ml of acetic acid into 50 ml of deionized water containing 4 g of p-phenylenediamine, and stir the mixture at 90° C. for 24 h, then filter and wash with a large amount of hot water, and then vacuum Drying gives the product 1,3-bis(4-aminophenyl)urea. Add 1g of 1,3-bis(4-aminophenyl)urea, 1.4g of cyanuric chloride, and 400mg of ZIF-67 into 10ml of dry dimethyl sulfoxide, keep the reaction temperature at 15°C, and add N , N-diisopropylethylamine 2ml, stirred for 24 hours, after the reaction was completed, the crude product was added to ice to form a solid, and then it was filtered and washed with dichloromethane, tetrahydrofuran, and ethyl acetate to obtain ZIF-67@TU - POP composite catalyst.

[0044] 3. Application of ZIF-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com