A kind of method for preparing complex surfactant/la-ni-mo-w co-deposition coating on copper substrate

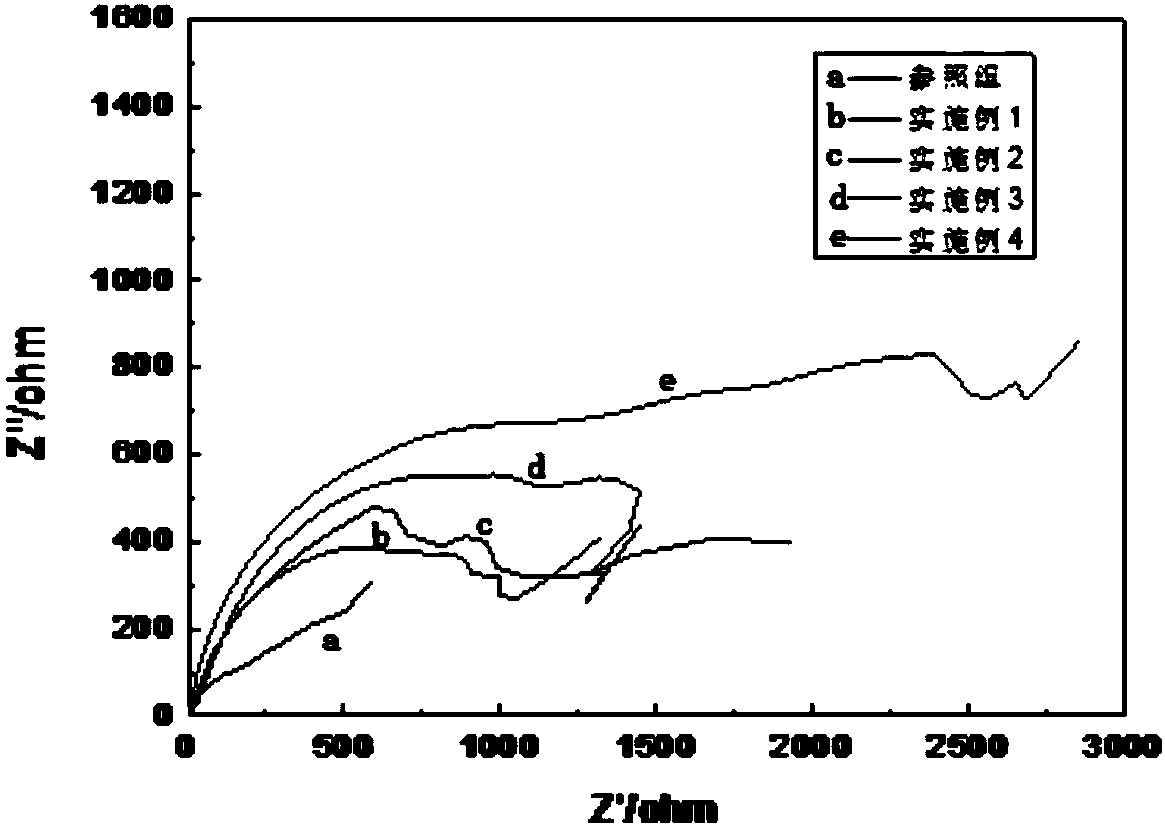

A technology of surfactant and copper matrix is applied in the field of preparing compound surfactant/La-Ni-Mo-W co-deposition coating, which can solve the problem of no introduction of rare earth elements and surfactants, poor coating stability and chemical activity , low hydrogen evolution overpotential and other problems, to achieve the effect of simple preparation method, high corrosion resistance and high chemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

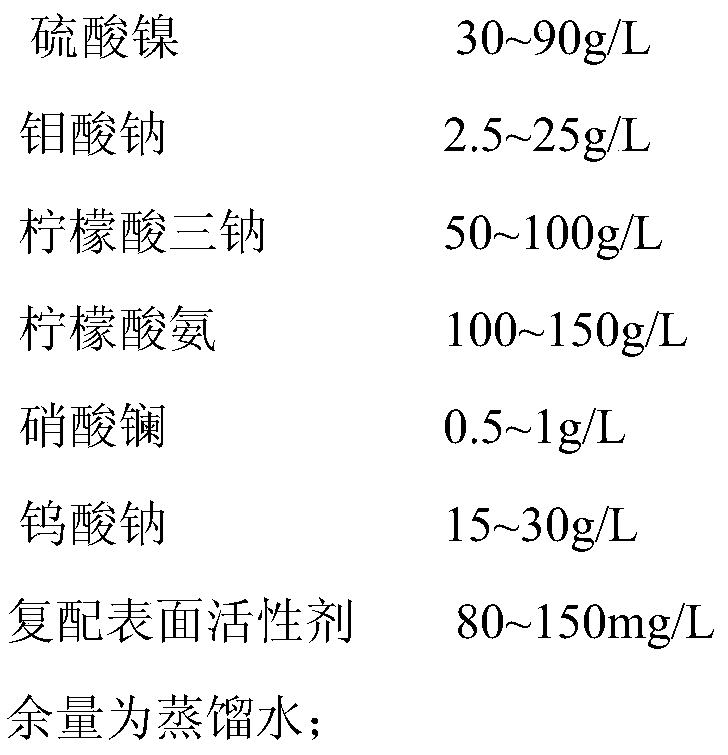

Embodiment 1

[0023] The specification of the copper substrate is: 50mm×20mm×3mm.

[0024] ①Polishing of copper sheet: Use 400#, 800#, 1200#, 2000# metallographic sandpaper to polish the copper sheet in turn to remove the oxide layer on the surface of the copper sheet. Then rinse with deionized water and set aside.

[0025] ② Degreasing of copper sheet: put the copper sheet into 100ml sodium hydroxide solution with a concentration of 20wt%, and ultrasonically treat it at 55°C for 15 minutes to remove oil. Then rinse with deionized water and set aside.

[0026] ③ Etching of the copper sheet: Put the copper sheet into 100ml of nitric acid solution with a concentration of 30wt%, treat it at 30°C for 4 minutes, then rinse it repeatedly with deionized water, and set it aside.

[0027] ④ Copper sheet activation: Put the copper sheet into 100ml hydrochloric acid solution with a concentration of 10wt%, treat it at 20°C for 7 minutes, then rinse it repeatedly with deionized water, and set it aside...

Embodiment 2

[0034] The specification of the copper substrate is: 50mm×20mm×3mm.

[0035] ①Polishing of copper sheet: Use 400#, 800#, 1200#, 2000# metallographic sandpaper to polish the copper sheet in turn to remove the oxide layer on the surface of the copper sheet. Then rinse with deionized water and set aside.

[0036] ② Degreasing of copper sheet: put the copper sheet into 100ml sodium hydroxide solution with a concentration of 20wt%, and ultrasonically treat it at 55°C for 15 minutes to remove oil. Then rinse with deionized water and set aside.

[0037] ③ Etching of the copper sheet: Put the copper sheet into 100ml of nitric acid solution with a concentration of 30wt%, treat it at 30°C for 4 minutes, then rinse it repeatedly with deionized water, and set it aside.

[0038] ④ Copper sheet activation: Put the copper sheet into 100ml hydrochloric acid solution with a concentration of 10wt%, treat it at 20°C for 7 minutes, then rinse it repeatedly with deionized water, and set it aside...

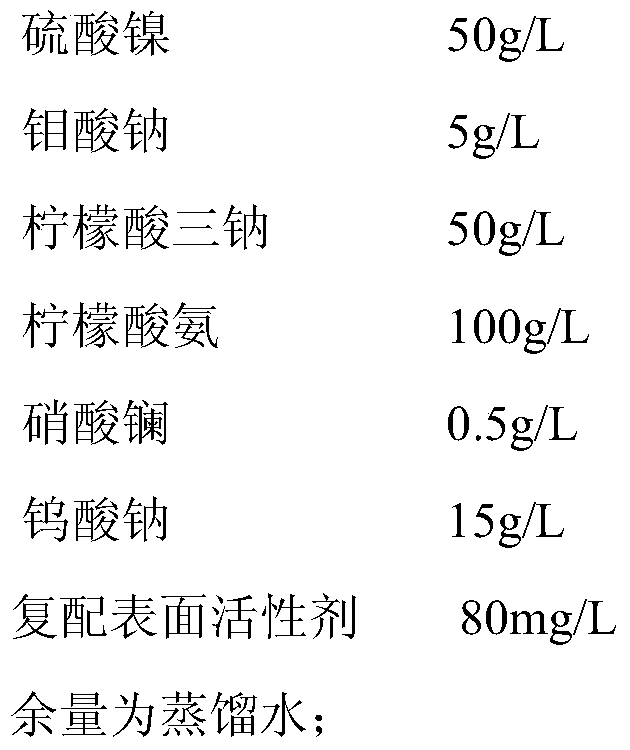

Embodiment 3

[0045] The specification of the copper substrate is: 50mm×20mm×3mm.

[0046] ①Polishing of copper sheet: Use 400#, 800#, 1200#, 2000# metallographic sandpaper to polish the copper sheet in turn to remove the oxide layer on the surface of the copper sheet. Then rinse with deionized water and set aside.

[0047] ② Degreasing of copper sheet: put the copper sheet into 100ml sodium hydroxide solution with a concentration of 20wt%, and ultrasonically treat it at 55°C for 15 minutes to remove oil. Then rinse with deionized water and set aside.

[0048] ③ Etching of the copper sheet: Put the copper sheet into 100ml of nitric acid solution with a concentration of 30wt%, treat it at 30°C for 4 minutes, then rinse it repeatedly with deionized water, and set it aside.

[0049] ④ Copper sheet activation: Put the copper sheet into 100ml hydrochloric acid solution with a concentration of 15wt%, treat it at 20°C for 7 minutes, then rinse it repeatedly with deionized water, and set it aside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com