A method for preparing silicon nanowires on a single crystal silicon substrate

A technology of silicon nanowires and single crystal silicon is applied in the field of preparing silicon nanowires on a single crystal silicon substrate, which can solve the problem of high cost and achieve the effects of easy production, low cost and wide application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

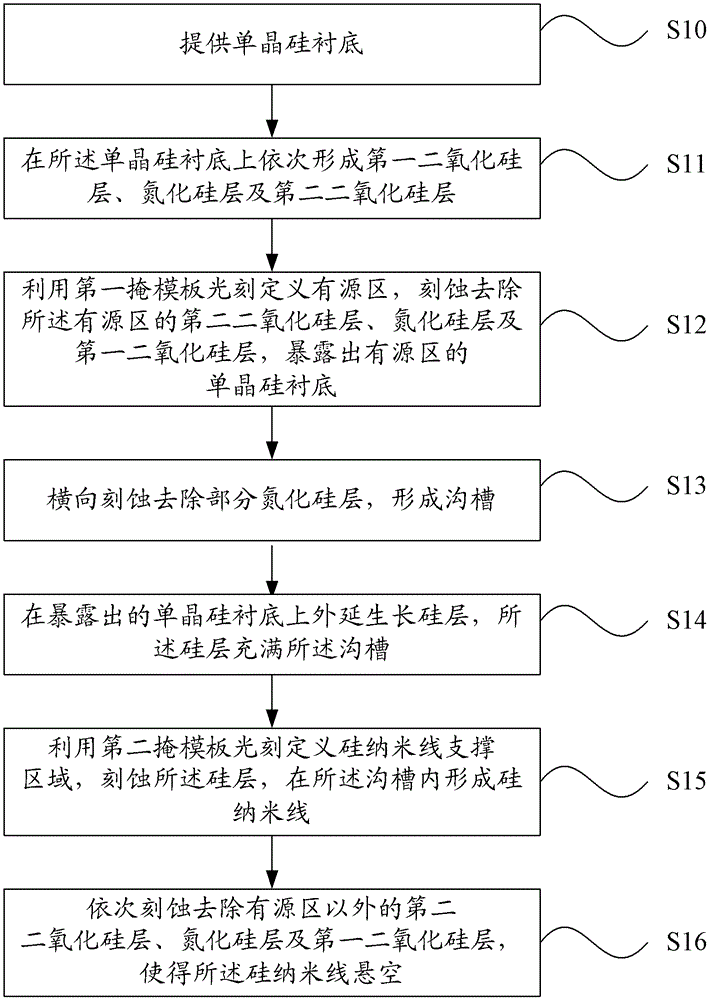

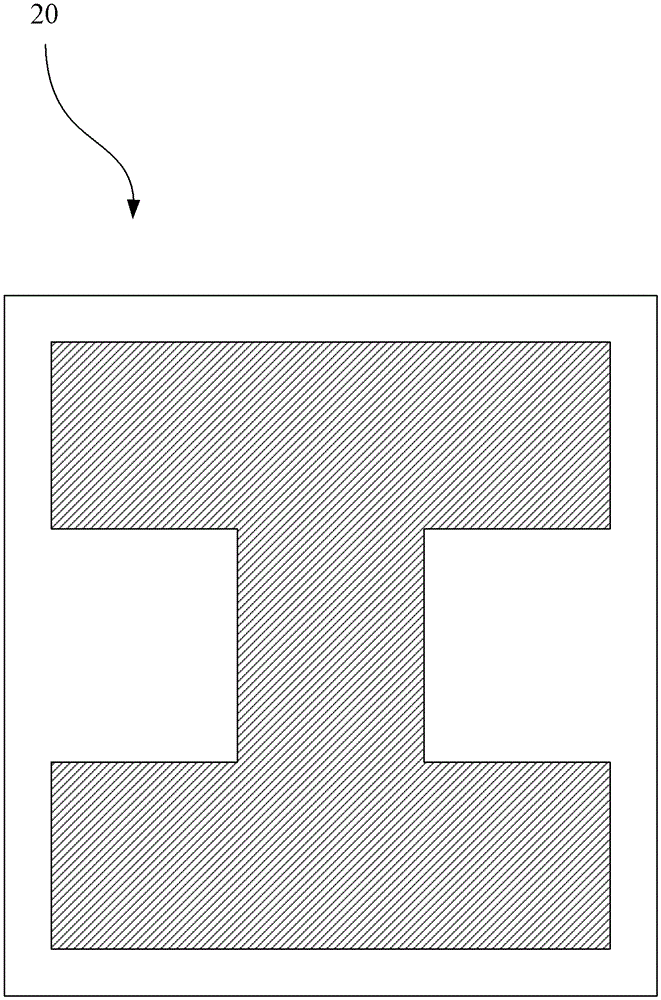

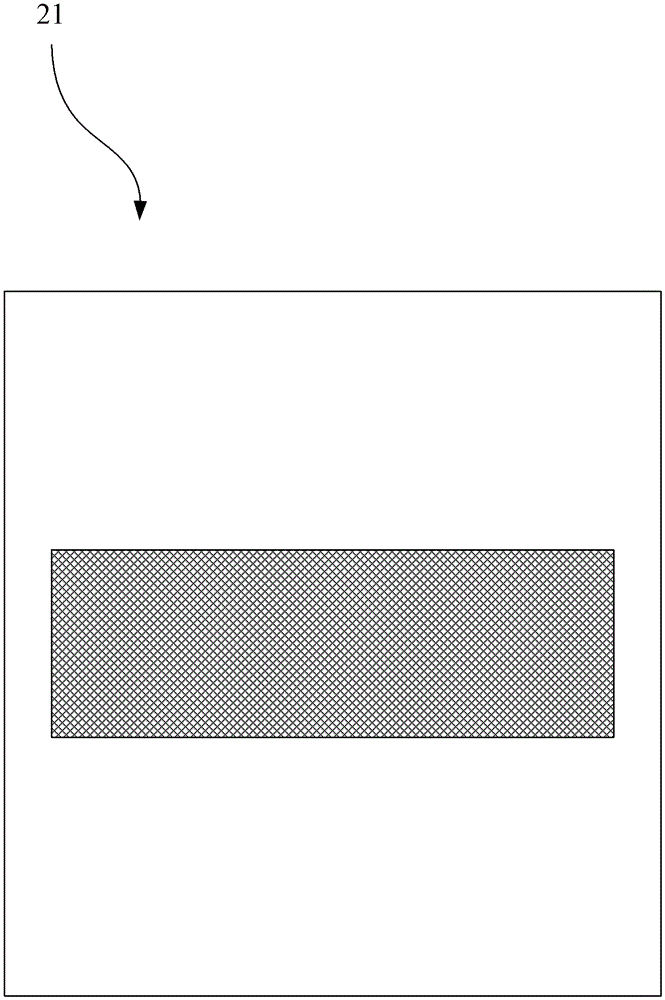

[0052] Please refer to Figure 2a-2c , Figure 3a-3g and Figure 4 ,in, Figure 2a is a schematic top view of the first mask used in the method for preparing silicon nanowires on a single crystal silicon substrate according to Embodiment 1 of the present invention; Figure 2b is a schematic top view of the second mask used in the method for preparing silicon nanowires on a single crystal silicon substrate according to Embodiment 1 of the present invention; Figure 2c It is a schematic diagram of registration with the first mask when the second mask is used in the method for preparing silicon nanowires on a single crystal silicon substrate according to Embodiment 1 of the present invention; Figure 3a-3g It is the method for preparing silicon nanowires on a single crystal silicon substrate according to Embodiment 1 of the present invention. Figure 2c Schematic diagram of the cross-sectional process in the direction indicated by AA' in the middle; Figure 4 It is the metho...

Embodiment 2

[0065] Please refer to Figures 5a-5c and Image 6 ,in, Figure 5a is a schematic top view of the first mask used in the method for preparing silicon nanowires on a single crystal silicon substrate according to Embodiment 2 of the present invention; Figure 5b is a schematic top view of the second mask used in the method for preparing silicon nanowires on a single crystal silicon substrate according to Embodiment 2 of the present invention; Figure 5c It is a schematic diagram of registration with the first mask when the second mask is used in the method for preparing silicon nanowires on a single crystal silicon substrate according to Embodiment 2 of the present invention; Image 6 It is the method for preparing silicon nanowires on a single crystal silicon substrate according to the second embodiment of the present invention. Figure 5c The schematic cross-sectional view in the direction indicated by AA'.

[0066] The difference between this embodiment and Embodiment 1 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com