Method for preparing multifunctional composite material from caragana korshinskii and graphite tailings

A technology of Caragana caragana and graphite tailings, applied in chemical instruments and methods, soil conditioning materials, applications, etc., can solve the problems of preparing multi-functional composite water-saving materials, no precedents for applications, etc., and reduce equipment requirements , fast water absorption and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

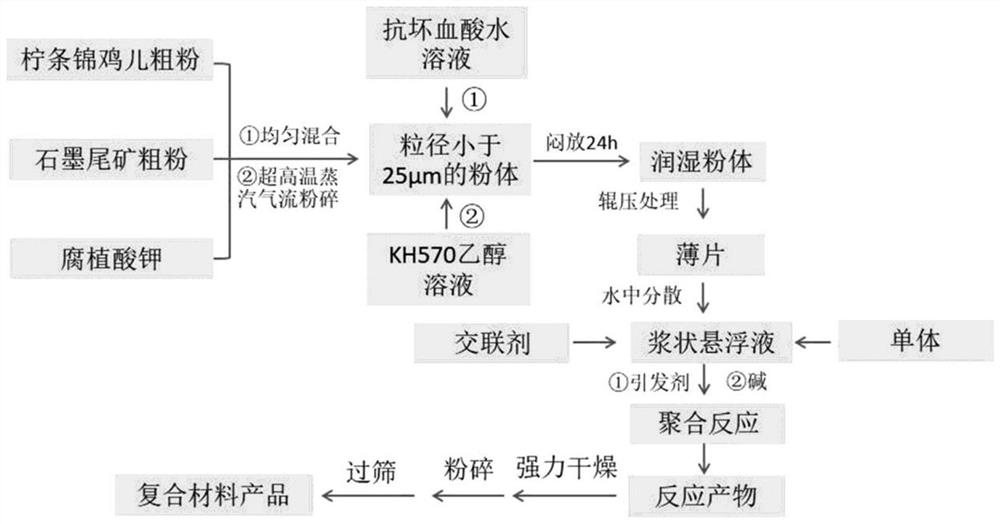

[0037] figure 1 A flow chart of the technical process of the method for preparing multifunctional composite materials using Caragana caragana and graphite tailings provided in the embodiment of the present application. see figure 1 , the preparation method comprises the steps of:

[0038] (1) Caragana caragana twig coarse powder, graphite tailings coarse powder and potassium humate are uniformly mixed in a certain proportion, and then ultra-high temperature steam jet crushing is carried out to obtain a surface-active powder with a particle size of less than 25 μm;

[0039] (2) Spray an aqueous solution containing ascorbic acid into the powder obtained in step (1), then spray into an ethanol solution containing KH570, control the total water content of the powder to be 30-45%, mix well and place in a closed container 24h;

[0040] (3) Rolling the mixture obtained in step (2) for 3 to 5 times to obtain a sheet with a thickness of 0.5 to 2 mm;

[0041] (4) Disperse the flakes...

Embodiment 1

[0057] After fully mixing 20kg of caragana twig coarse powder, 30kg of graphite tailings coarse powder and 50kg of potassium humate, ultra-high temperature steam jet crushing treatment is carried out to obtain a surface-active powder with a particle size of less than 25 μm. Then, spray 42.8L of aqueous solution containing 2kg of ascorbic acid evenly into the powder, then spray 10L of ethanol solution containing 2kg of KH570, mix well to obtain a powder with a total water content of 30%, and then transfer it to an airtight container for 24 hours . The semi-wet powder that is fully infiltrated after standing is rolled for 3 to 5 times to obtain a thin sheet with a thickness of 1 mm. Disperse the obtained flakes into 500kg of water under mechanical stirring, then add 185kg of acrylic acid and 2kg of N,N'-methylenebisacrylamide, and fully stir to form a uniform slurry suspension. Transfer the suspension into a reaction tank, bubble with nitrogen for 1 h, then add 3.7 kg of initia...

Embodiment 2

[0059] After fully mixing 40kg of caragana twig coarse powder, 10kg of graphite tailings coarse powder and 50kg of potassium humate, ultra-high temperature steam jet crushing treatment is performed to obtain a surface-active powder with a particle size of less than 25 μm. Then, spray 81.8L of aqueous solution containing 5kg of ascorbic acid evenly into the powder, then spray 10L of ethanol solution containing 5kg of KH570, mix well to obtain a powder with a total water content of 45%, and then transfer it to an airtight container for 24 hours . Roll the semi-wet powder that is fully infiltrated after standing for 3 to 5 times to obtain a thin sheet with a thickness of 0.5 mm. Disperse the obtained flakes into 1500kg of water under mechanical stirring, then add 100kg of acrylamide and 6kg of N,N'-methylenebisacrylamide, and fully stir to form a uniform slurry suspension. Transfer the suspension into a reaction tank, bubble with nitrogen for 1 hour, then add 5kg of initiator am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com