Composite remediation agent for heavy metal contaminated soil and application method

A technology for composite remediation and contaminated soil, applied in the field of remediation of heavy metal-contaminated soil, can solve the problems of unsuitable resource reuse, high treatment cost, and difficulty in mud-water separation, so as to change the oxidation-reduction potential and heavy metal valence state, and promote oxidation reduction. Effect of precipitation and reduction of heavy metal toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

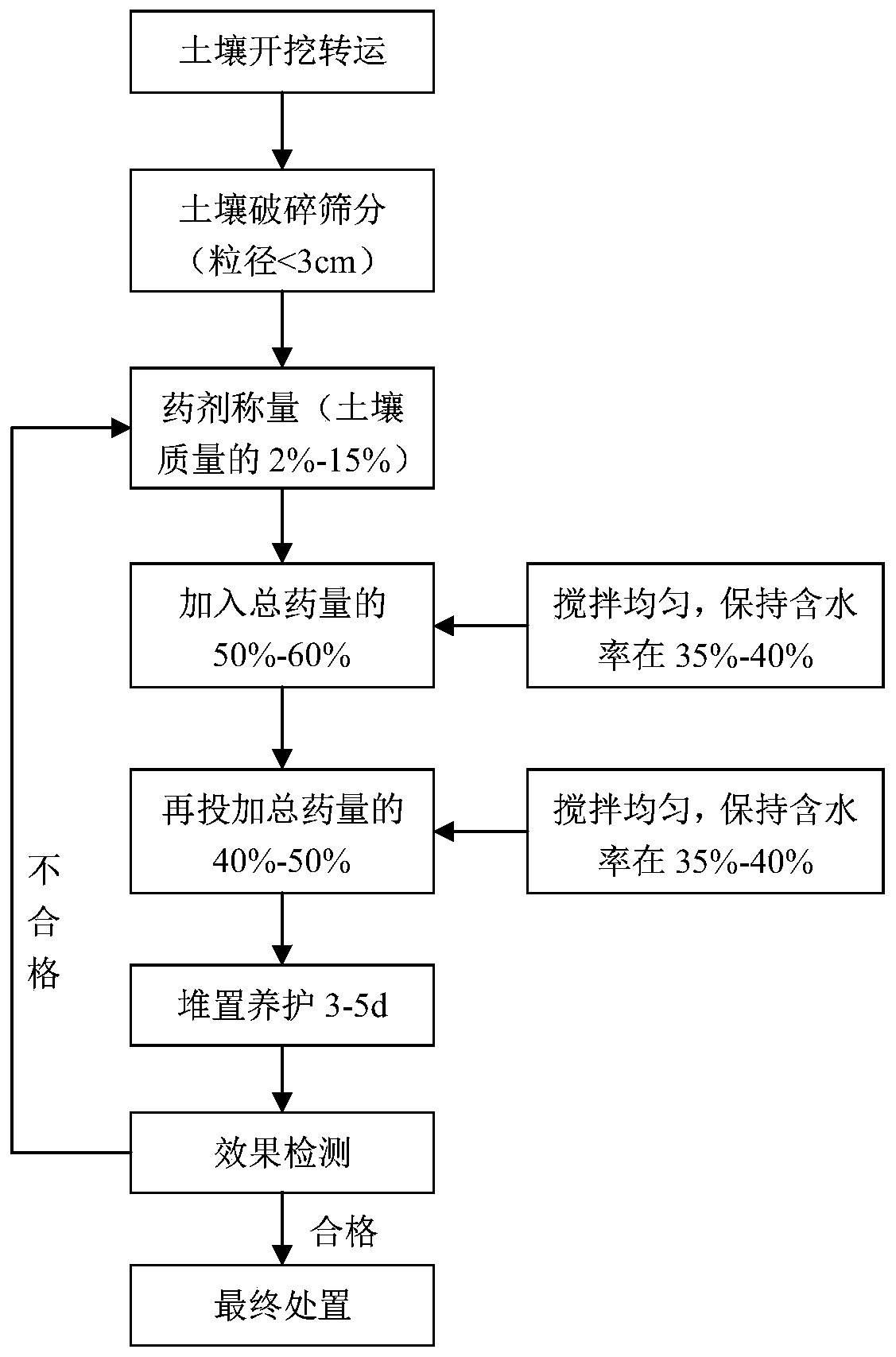

Method used

Image

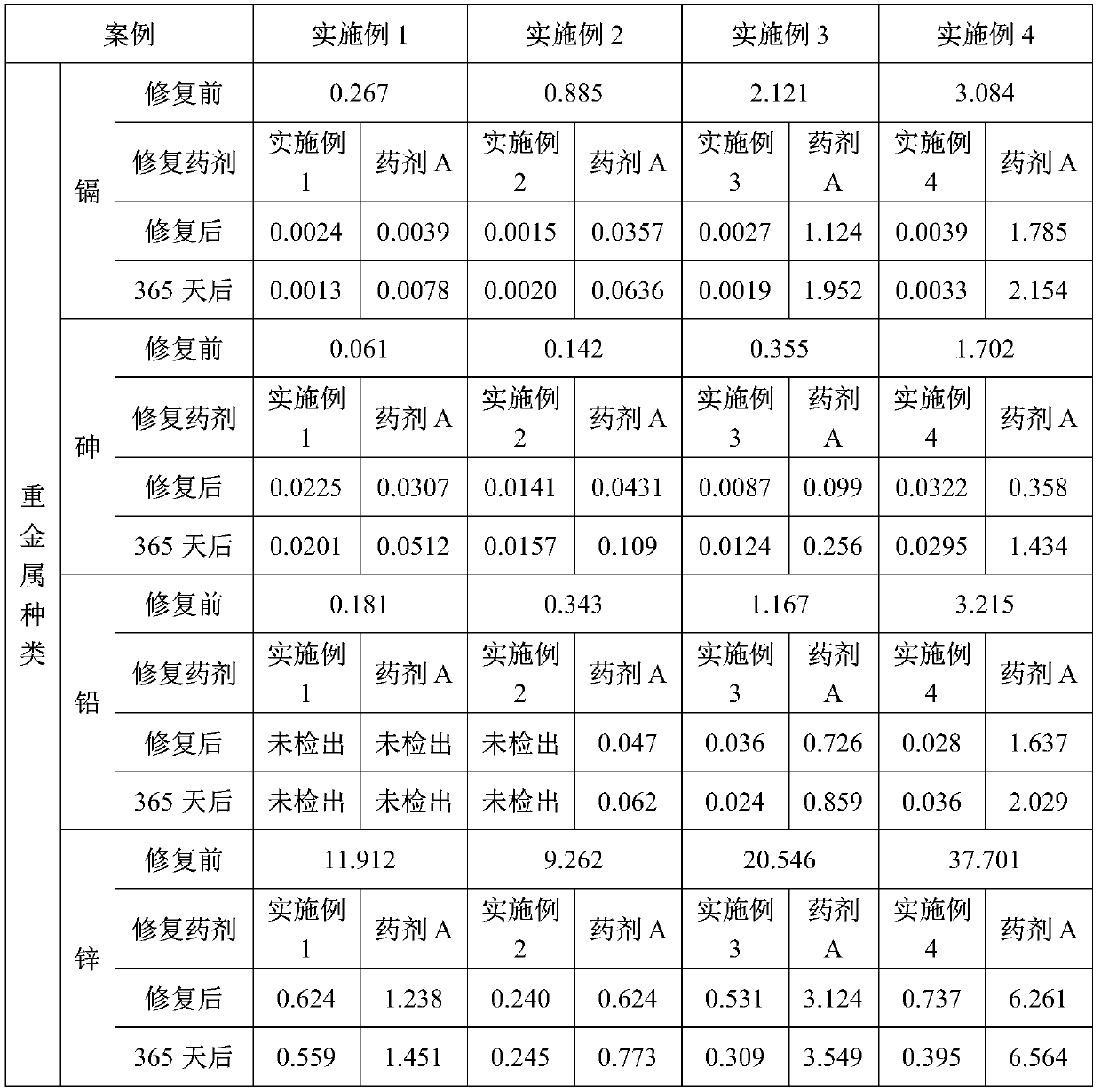

Examples

Embodiment 1

[0037] The composition of the soil composite restoration agent is as follows in parts by mass: 30 parts of ferrous sulfate; 5 parts of calcium sulfide; 40 parts of lime; 19 parts of dolomite, 3 parts of black humic acid and 3 parts of fulvic acid.

[0038] Dry the iron-based agents, sulfur-based agents and calcium-based agents separately, grind them through a 150-mesh sieve, activate them at 105°C for 1.5 hours, mix them, add organic matter, and mix them evenly to obtain a composite repair agent .

Embodiment 2

[0040] The composition of the soil composite restoration agent is as follows in parts by mass: 25 parts of polyferric sulfate; 4 parts of sodium polysulfide; 4 parts of sodium sulfide; 20 parts of calcium carbonate; 28 parts of Portland cement; acid 3 parts.

[0041] Dry the iron-based agents, sulfur-based agents and calcium-based agents separately, grind them through a 150-mesh sieve, activate them at 105°C for 1.5 hours, mix them, add organic matter, and mix them evenly to obtain a composite repair agent .

Embodiment 3

[0043] The composition of the soil composite restoration agent is calculated in parts by mass: 30 parts of ferric oxide; 8 parts of ferrous sulfide; 2 parts of calcium sulfide; 25 parts of calcium hydroxide; 30 parts of lime; 2.5 servings.

[0044]Dry the iron-based agents, sulfur-based agents, and calcium-based agents, grind them through a 100-mesh sieve, activate them at 150°C for 2 hours, mix them, add organic matter, and mix them evenly to obtain a composite restoration agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com