Preparation method for MOFs heavy metal collecting agent

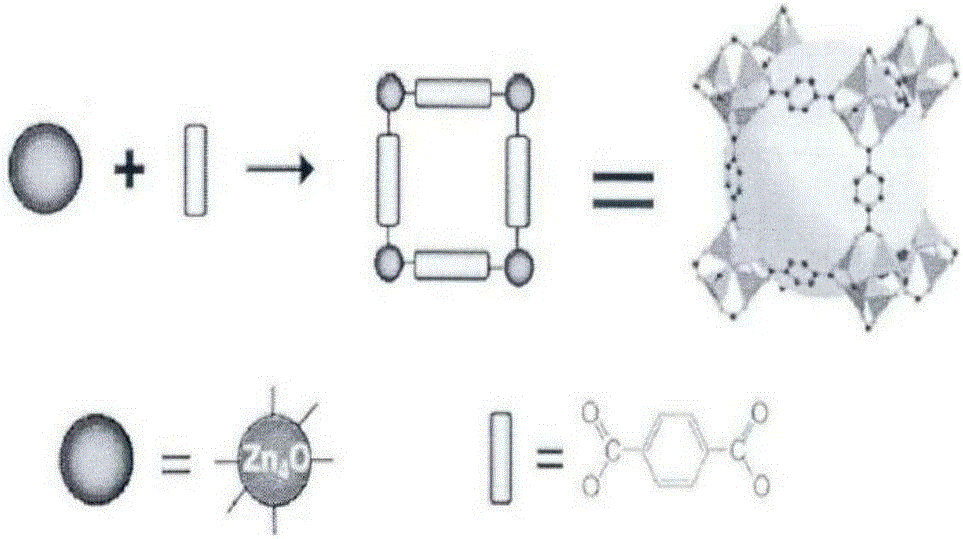

A heavy metal trapping agent and metal salt technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of difficult recycling of heavy metals, difficult regeneration of adsorbents, and small adsorption capacity etc. to achieve excellent adsorption capacity, stable properties, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

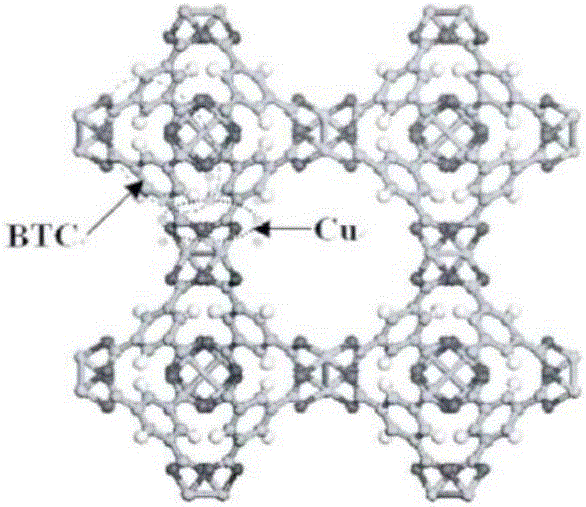

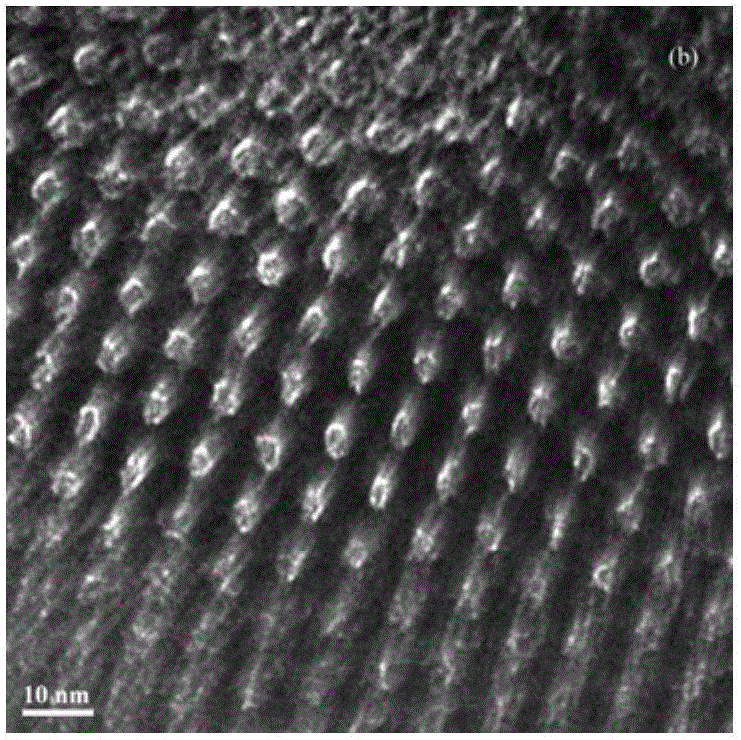

[0031] Take 1 part of trimerbenzoic acid (BTC), 1.5 parts of zinc nitrate and 5 parts of dimethylformamide (DMF) and mix them to fully dissolve them. Then add 0.6 parts of sodium thiocyanate, continue to stir and dissolve. Move the above mixture into a stainless steel high-pressure hydrothermal reaction kettle, and control the temperature rise rate to 10-15°C / min; when the temperature rises to 150°C, stop the temperature rise, and keep warm at this temperature for 2 hours. After the reaction, the temperature was naturally lowered to below 80°C, and the materials in the reactor were taken out, washed with pure water for more than 3 times, dried at 100°C, and then activated at 210°C, ready for use after activation.

[0032] Put 0.2g of mercapto-containing MOFs prepared above into a copper sulfate solution containing 25ppm. After shaking for 10 minutes, the typical blue color of copper sulfate can be seen to disappear. After ICP-MS detection, Cu 2+ The concentration is lower tha...

Embodiment 2

[0035] Take 1 part of trimerbenzoic acid (BTC), 1.5 parts of zinc nitrate and 5 parts of dimethylformamide (DMF) and mix them to fully dissolve them. Then add 0.3 part of sodium thiocyanate, continue to stir and dissolve. Move the above mixture into a stainless steel high-pressure hydrothermal reaction kettle, and control the temperature rise rate to 10-15°C / min; when the temperature rises to 150°C, stop the temperature rise, and keep warm at this temperature for 2 hours. After the reaction, the temperature was naturally lowered to below 80°C, and the materials in the reactor were taken out, washed with pure water for more than 3 times, dried at 100°C, and then activated at 210°C, ready for use after activation.

[0036] Put 0.2g of mercapto-containing MOFs prepared above into a copper sulfate solution containing 25ppm. After shaking for 10 minutes, the typical blue color of copper sulfate can be seen to disappear. After ICP-MS detection, Cu 2+ The concentration is lower than...

Embodiment 3

[0038]Take 1 part of trimerbenzoic acid (BTC), 1.8 parts of zinc nitrate and 5 parts of dimethylformamide (DMF) and mix them to fully dissolve them. Then add 0.4 part of sodium thiocyanate, continue to stir and dissolve. Move the above mixture into a stainless steel high-pressure hydrothermal reaction kettle, and control the temperature rise rate to 10-15°C / min; when the temperature rises to 150°C, stop the temperature rise, and keep warm at this temperature for 2 hours. After the reaction, the temperature was naturally lowered to below 80°C, and the materials in the reactor were taken out, washed with pure water for more than 3 times, dried at 100°C, and then activated at 210°C, ready for use after activation.

[0039] Put 0.2g of mercapto-containing MOFs prepared above into a copper sulfate solution containing 25ppm. After shaking for 10 minutes, the typical blue color of copper sulfate can be seen to disappear. After ICP-MS detection, Cu 2+ The concentration is lower than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com