Calcining method for belt sintering machine

A belt-type sintering machine and roasting technology, which is applied in the field of lead smelting, can solve problems such as the influence of sintering and roasting effects, difficulty in price and procurement, and heavy oil pollution, and achieve the effects of improved technical indicators, low cost, and good fire control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

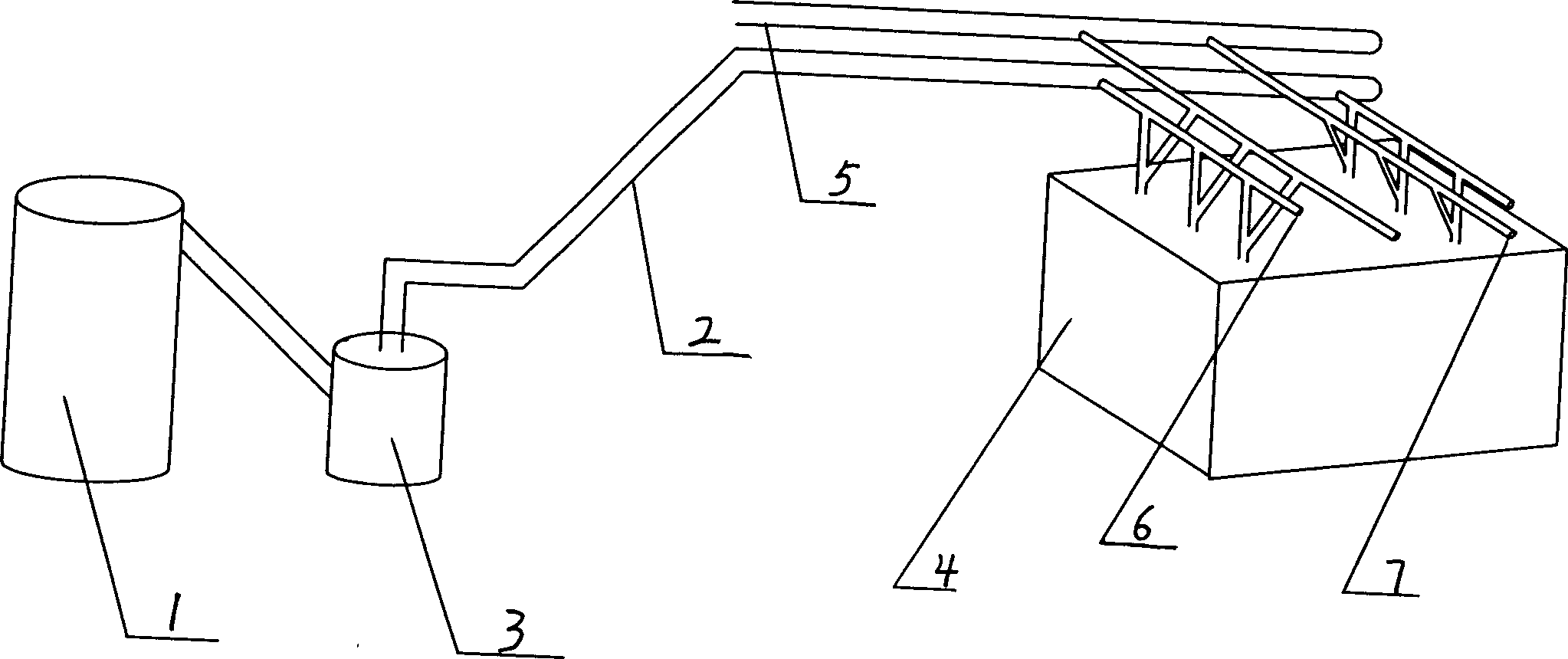

[0008] Such as figure 1 As shown, the present invention selects coal gas to ignite and burn the materials on the lead sintering machine, and keeps the gas supply continuous and stable. Coal gas is produced by the gas generator 1, and the gas produced by the gas generator 1 is sent to the cyclone dust collector 3 through the gas pipeline 2. After the dust is removed by the cyclone dust collector 3, the gas is sent to the gas branch pipe 6 through the gas pipeline 2, and the combustion-supporting air Enter the combustion-supporting air branch pipe 7 through the combustion-supporting air pipe 5, the gas branch pipe 6 and the combustion-supporting air branch pipe 7 pass through, and then connect to the furnace of the ignition furnace 4 through the gas burner, and the combustion-supporting air and the gas are fully mixed and enter the point through the gas burner Furnace hearth for combustion. The volume ratio of the combustion-supporting air and the gas is 1:1. The gas and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com