Method for roasting and preheating aluminum electrolysis cell using direct currents

An aluminum electrolytic cell and electrolytic cell technology, applied in the field of electrolysis, can solve the problems of unsuitable opening of the cell, high risk of electric shock, complicated operation, etc., and achieve the effects of reducing the start-up cost of roasting, good roasting effect, and uniform roasting temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

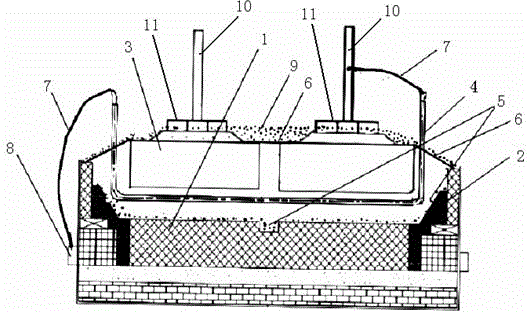

[0028] The electrolytic heat roasting preheating method for the electrolytic cell provided by the invention comprises the steps of filling the tank, energizing roasting and removing the metal resistance device, specifically through the following steps (such as figure 1 shown):

[0029] A. Clean the furnace, and lay a layer of cryolite on the surface of cathode carbon block 1 and artificial leg 2, with a thickness of 1±0.2mm;

[0030] B. Install the anode carbon block 3. When installing the anode carbon block, pay special attention to re-tightening the small box fixture to prevent the anode carbon block from sliding down;

[0031] C. Install the radiation heating tube 4, check the anode 3 and then lift the anode to install the radiation heating tube 4, and install a thermocouple probe in the tank to detect the heating temperature;

[0032] D. After installing the radiation heating tube 4, spread a layer of high temperature resistant asbestos board 6 with a thickness of 1.0cm o...

Embodiment 2

[0040] The electrolytic heat roasting preheating method for the electrolytic cell provided by the invention comprises the steps of filling the tank, energizing roasting and removing the metal resistance device, specifically through the following steps (such as figure 1 shown):

[0041] A. Clean the furnace, and lay a layer of cryolite on the surface of cathode carbon block 1 and artificial leg 2, with a thickness of 1±0.2mm;

[0042] B. Install the anode carbon block 3. When installing the anode carbon block, pay special attention to re-tightening the small box fixture to prevent the anode carbon block from sliding down;

[0043] C. Install the radiation heating tube 4, check the anode 3 and then lift the anode to install the radiation heating tube 4, and install a thermocouple probe in the tank to detect the heating temperature;

[0044] D. Lay a layer of high temperature resistant asbestos board 6 with a thickness of 1.5cm on the anode seam, middle seam and edge after the r...

Embodiment 3

[0050] The electrolytic heat roasting preheating method for the electrolytic cell provided by the invention comprises the steps of filling the tank, energizing roasting and removing the metal resistance device, specifically through the following steps (such as figure 1 shown):

[0051] A. Clean the furnace, and lay a layer of cryolite on the surface of cathode carbon block 1 and artificial leg 2, with a thickness of 1±0.2mm;

[0052] B. Install the anode carbon block 3. When installing the anode carbon block, pay special attention to re-tightening the small box fixture to prevent the anode carbon block from sliding down;

[0053] C. Install the radiation heating tube 4, check the anode 3 and then lift the anode to install the radiation heating tube 4, and install a thermocouple probe in the tank to detect the heating temperature;

[0054] D. Lay a layer of high temperature resistant asbestos board 6 with a thickness of 1.3cm on the anode seam, middle seam and edge after the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com