Method for extracting molybdenum from waste nickel-molybdenum catalyst

A waste catalyst and catalyst technology, applied in the direction of improving process efficiency, can solve the problems of high aluminum content, difficult separation of molybdenum and aluminum, etc., and achieve the effects of high recovery rate, easy crushing, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

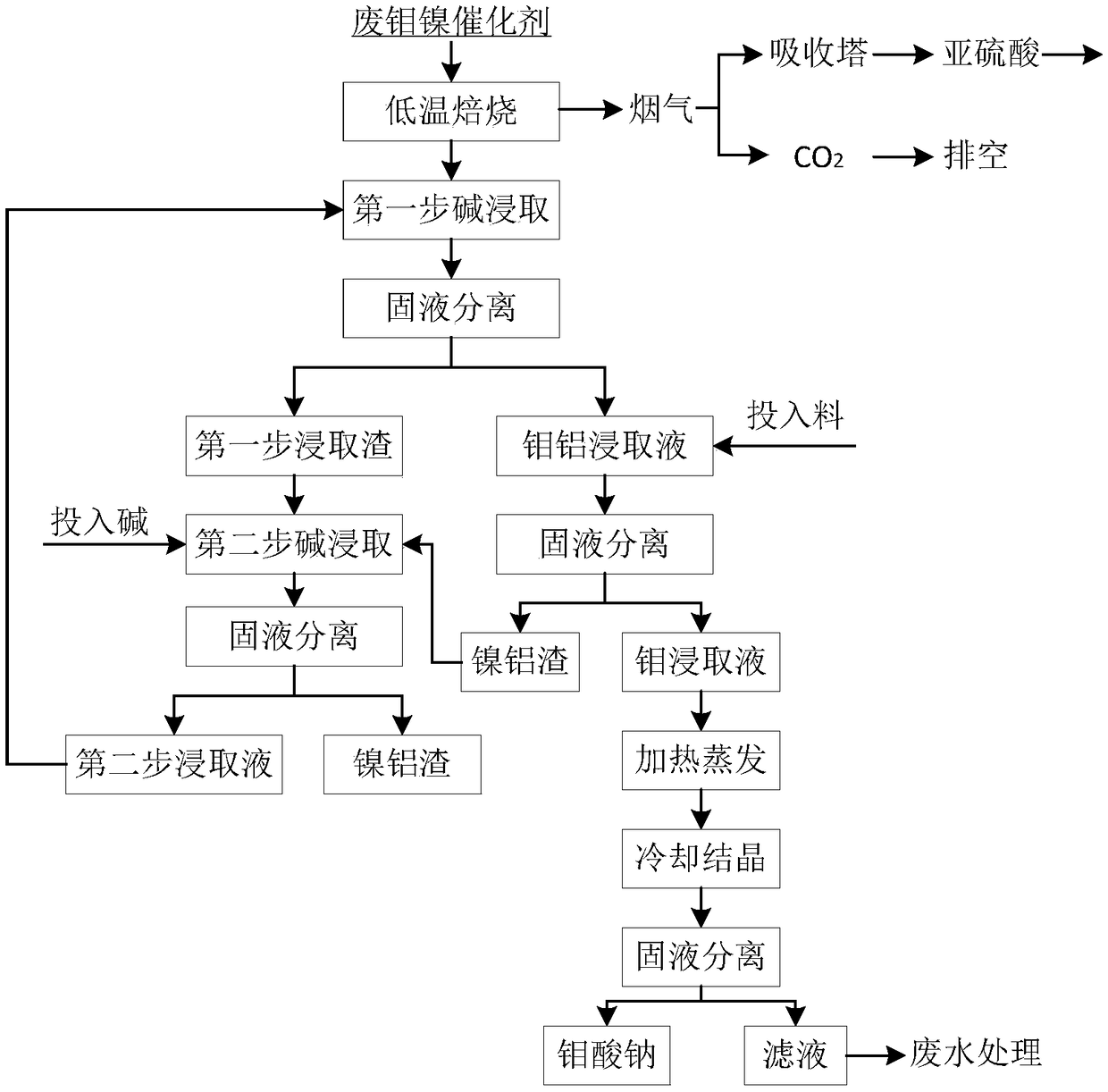

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Put the waste nickel-molybdenum catalyst to be treated into an electric heating type roaster for a period of low-temperature oxidation roasting, the roasting temperature is 600°C, and the roasting time is 2h, and the carbon and sulfur deposits on the spent catalyst are burned, and at the same time, the The valuable metal sulfides in the spent catalyst are converted into valuable metal oxides; the flue gas is introduced into the spray alkali scrubber through the fan to remove SO 2 smoke.

Embodiment 2~ Embodiment 4

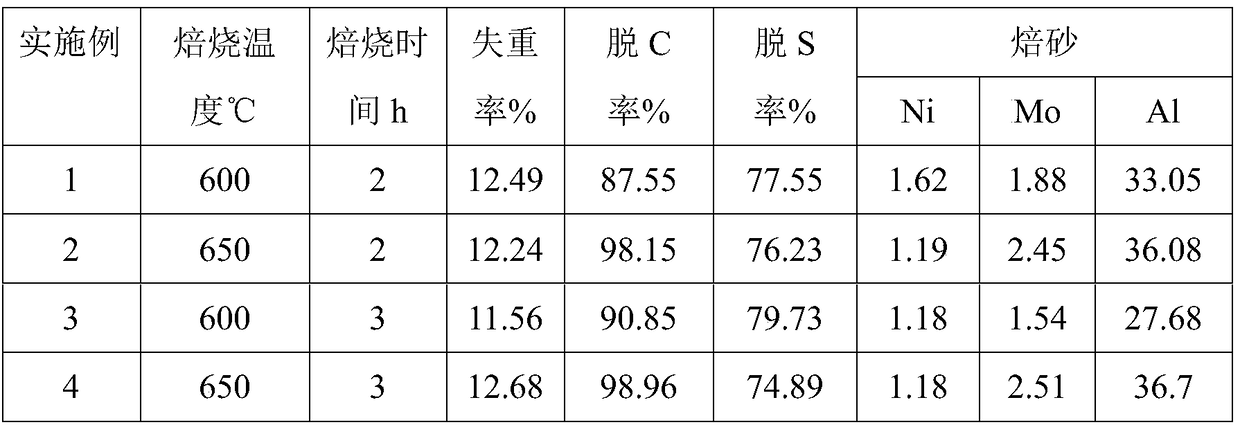

[0032] Examples 2 to 4: According to the calcination process of Example 1, different calcination results were obtained by changing the calcination temperature and calcination time, see Table 3.

[0033] The roasting result of table 3 embodiment 1~embodiment 4

[0034]

Embodiment 5

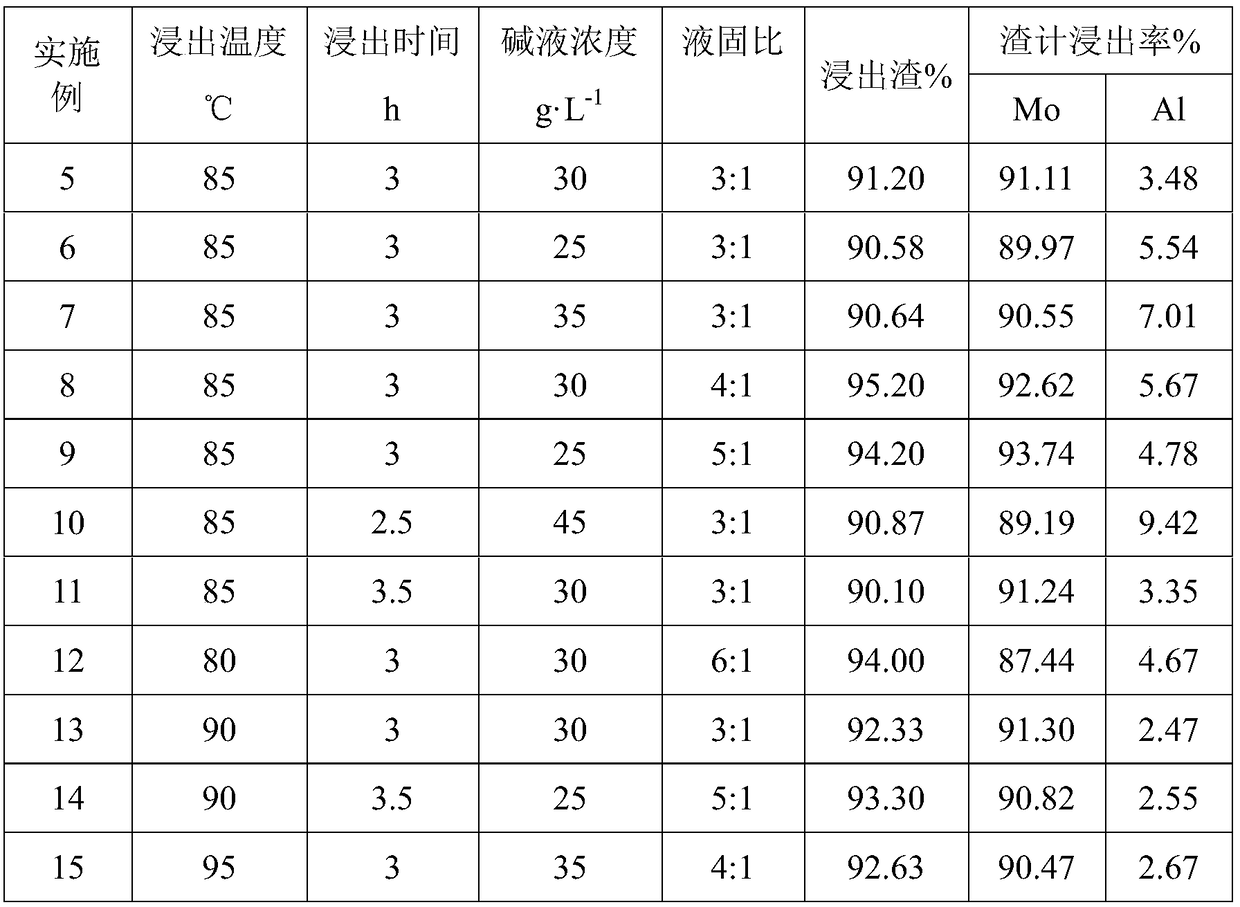

[0037] (1) Under normal pressure, dissolve part of the roasted material obtained in Example 2 in sodium carbonate solution for the first step of leaching, and leaching for 3 hours at 85°C and a stirring speed of 800rpm, the first step of leaching the concentration of lye 30g·L -1 , the liquid-solid ratio is 3:1, after leaching, the ore slurry is filtered to obtain the first step leaching slag and the leaching solution containing molybdenum and aluminum;

[0038] (2) Under normal pressure, dissolve the leaching slag obtained in step (1) in the first step in alkaline solution again for the second step of leaching, leaching at 85°C and a stirring speed of 800rpm for 3 hours, and the second step of leaching Take the lye concentration as 15g L -1 , the liquid-solid ratio is 3:1, after leaching, the ore slurry is filtered to obtain nickel-aluminum slag and the second step leaching solution;

[0039] (3) Under normal pressure, add part of the roasted material obtained in Example 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com