Production method of bilayer structure pellet and production equipment thereof

A technology with a double-layer structure and a manufacturing method is applied in the field of pellet production methods and equipment, and can solve the problems of less iron ore resources, poor particle size uniformity, difficulty in beneficiation, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

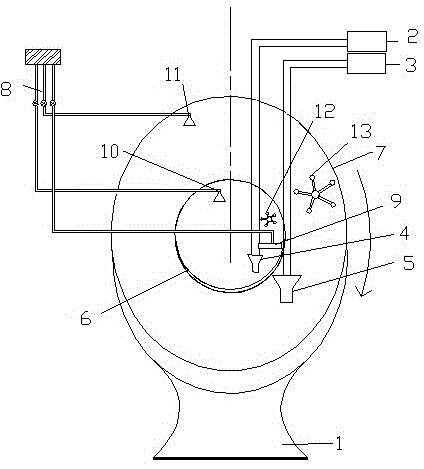

[0026] The manufacture method of double-layer structure pellet of the present invention is divided into following five steps and finishes:

[0027] A: Test raw material preparation:

[0028] Application purpose: resource recovery and utilization, adding part of gas ash to the pellets to produce magnesium-containing pellets.

[0029] Mineral powder characteristics: refer to the physical and chemical properties of the mineral powder used in Table 1. Ukrainian and domestic fine powders are high in grade, fine in particle size, and have a high spherical index; high magnesium powder contains MgO, CaO, and SiO 2 The composition is high, slag phase is easy to be produced, and high temperature is required for roasting; gas ash has high carbon content, is not easy to form balls, and is easy to stick when roasted, which will aggravate the ring formation of the rotary kiln. The raw material composition is shown in Table 1.

[0030]

[0031] Table 1 Physical and chemical properties of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com