Insulating paint of semi-inorganic environmental non-oriented silicon steel insulating paint and application thereof

A technology of oriented silicon steel and insulating coatings, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of unsatisfactory properties such as heat resistance and weldability, and achieve good water vapor absorption resistance and good surface resistivity , Excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

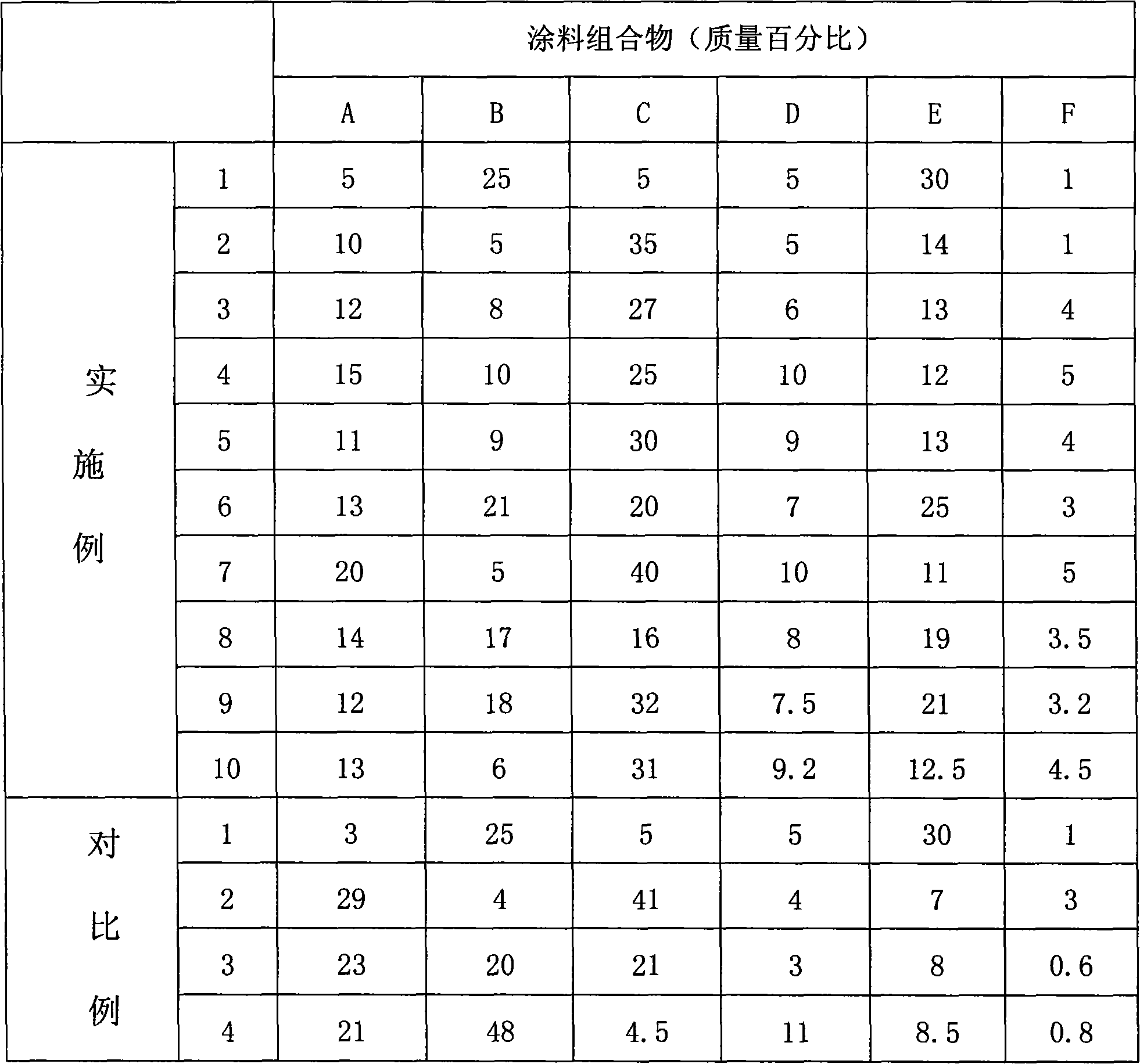

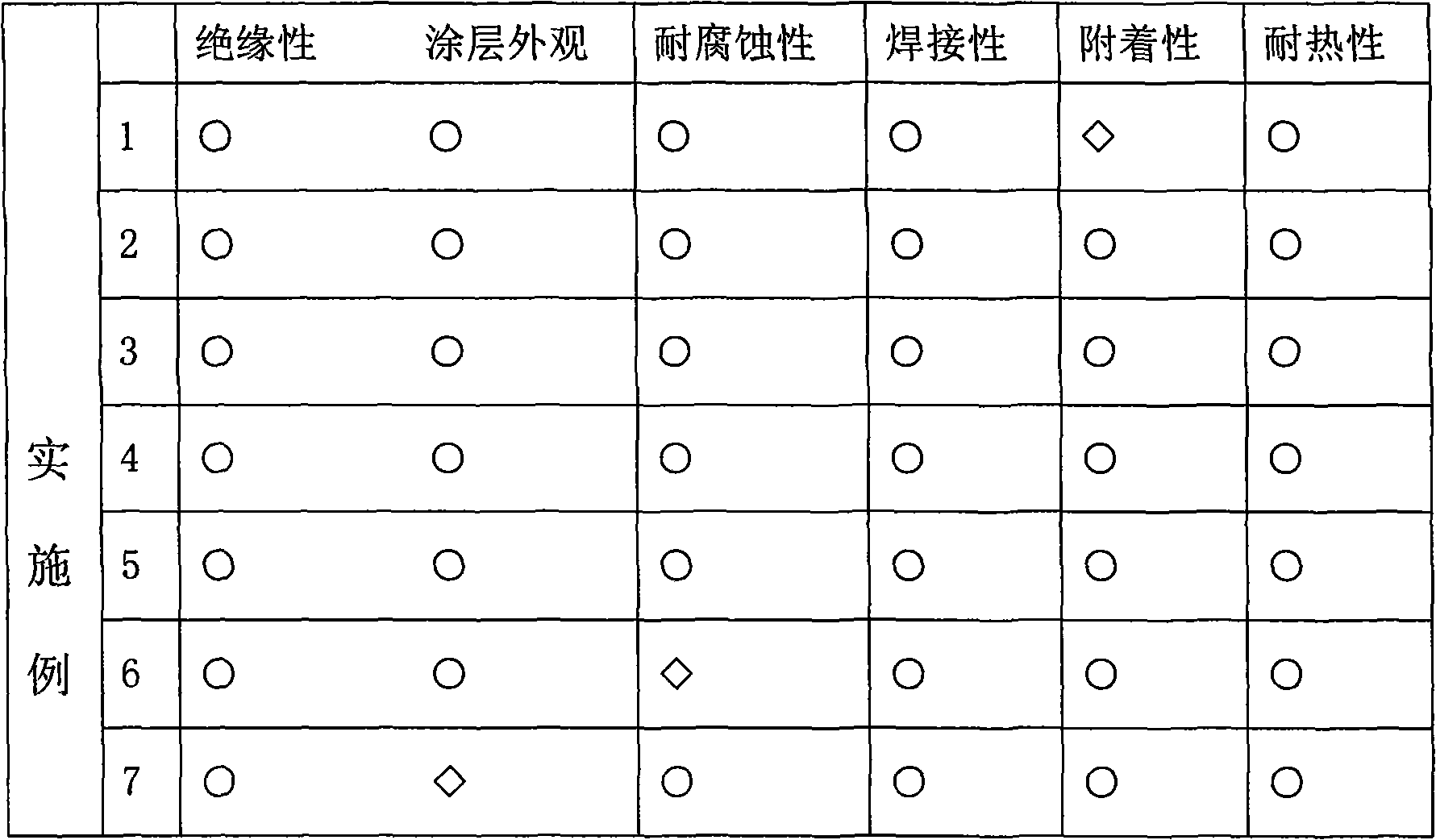

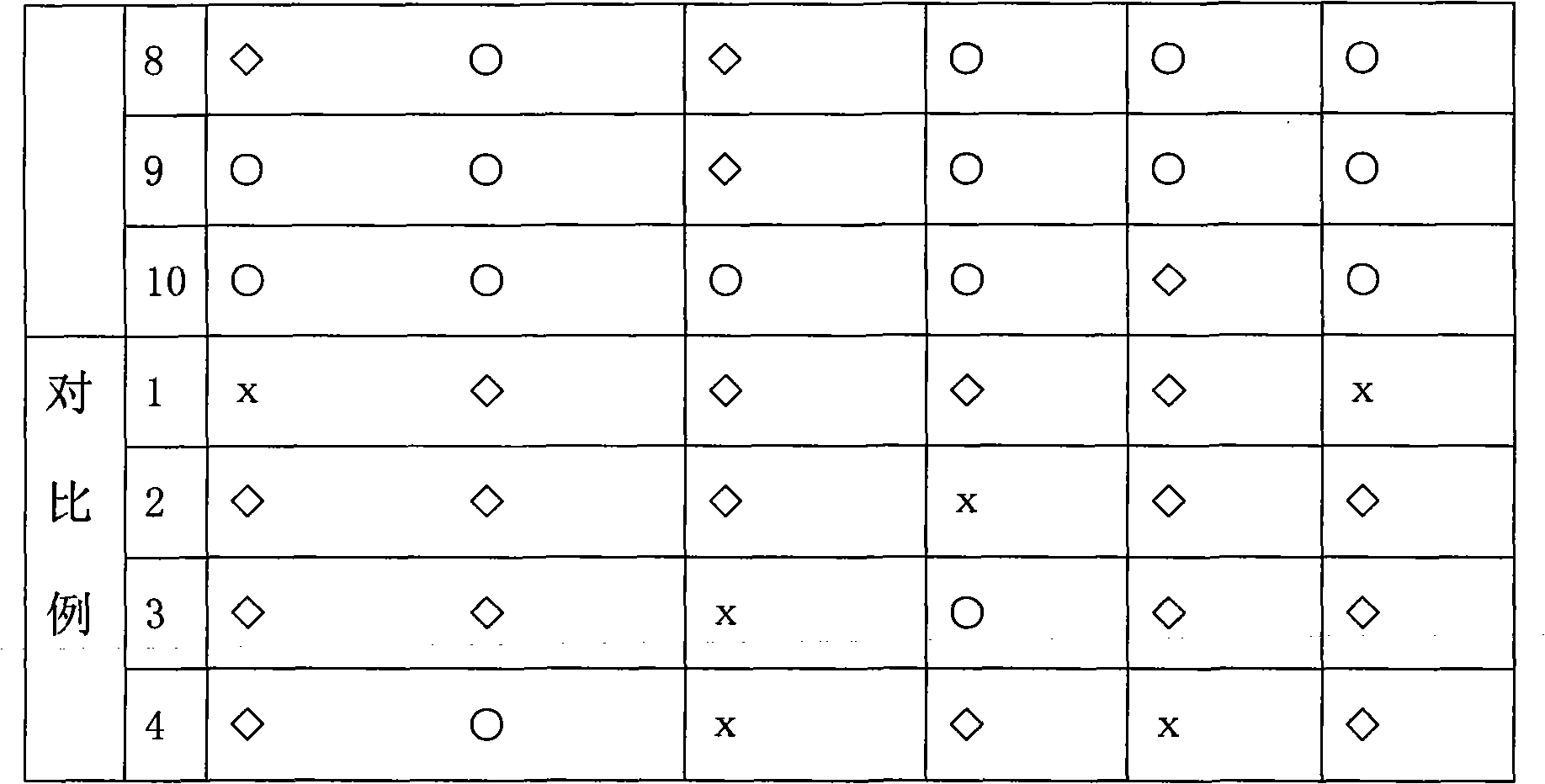

[0026] The insulating coating prepared according to the formula shown in Table 1 was coated on the non-oriented steel plate, and heat-treated at 650° C. for 30 seconds to obtain a silicon steel plate with an insulating coating film with a thickness of 1.5 μm.

[0027] The specific preparation steps are as follows: according to the formula ratio in Table 1, the corresponding amount of polyurethane-acrylate-ethylene oxide resin and deionized water are added to the reaction vessel, and then the corresponding amount of aluminum dihydrogen phosphate, isopropyl Magnesium alkoxide, zinc acetate, colloidal silicon dioxide and nonionic surfactant are stirred evenly to prepare the coating.

[0028] The formula of each composition is as shown in table 1 (surplus is deionized water):

[0029] Table 1 Composition of paint components

[0030]

[0031] (Note: A is magnesium isopropoxide, B polyurethane-acrylate-ethylene oxide resin, C is aluminum dihydrogen phosphate, D is zinc acetate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com