Synchronous tensioning and releasing control system for pre-tensioned track boards

A technology of synchronous stretching and control system, which is applied in the direction of manufacturing tools and ceramic molding machines, can solve the problems of low production efficiency, low yield rate, and inability to synchronously stretch track plates, etc., and achieve the goal of improving the qualified rate of finished products and increasing productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

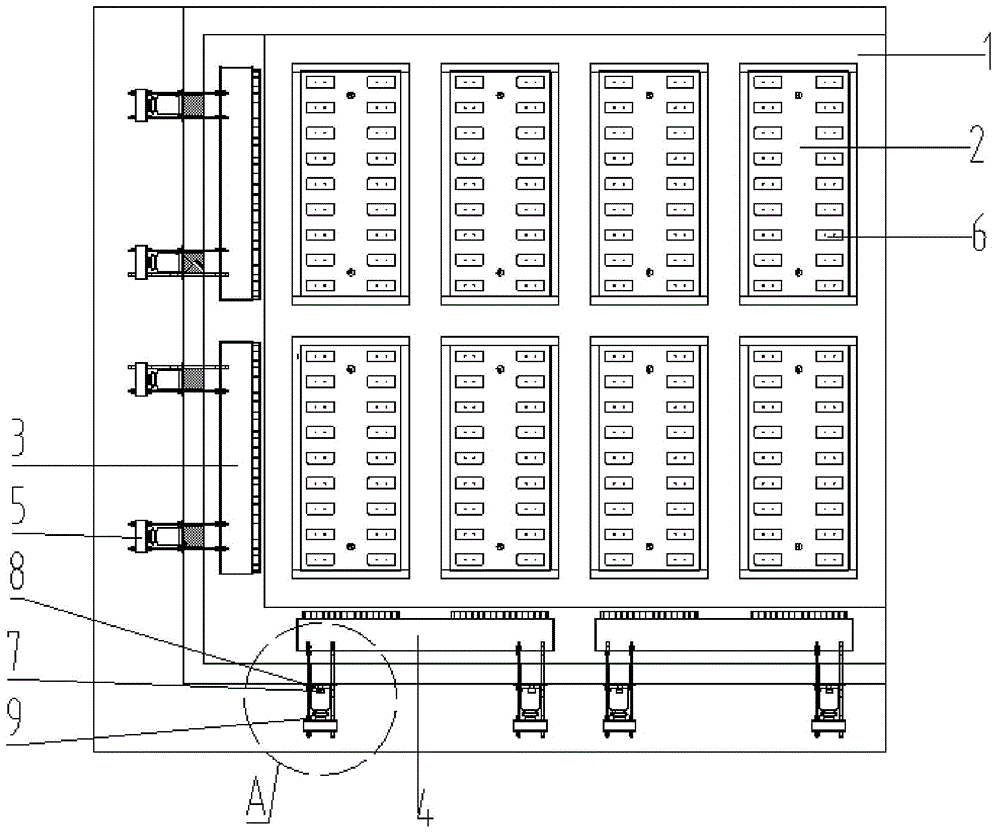

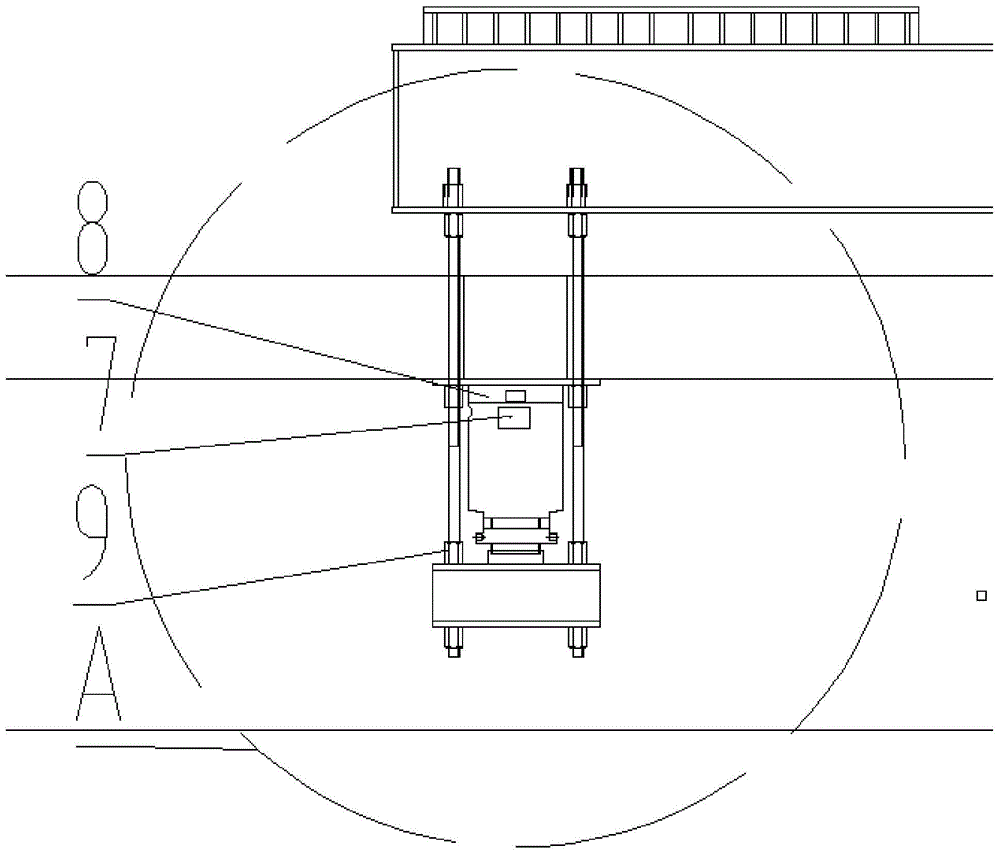

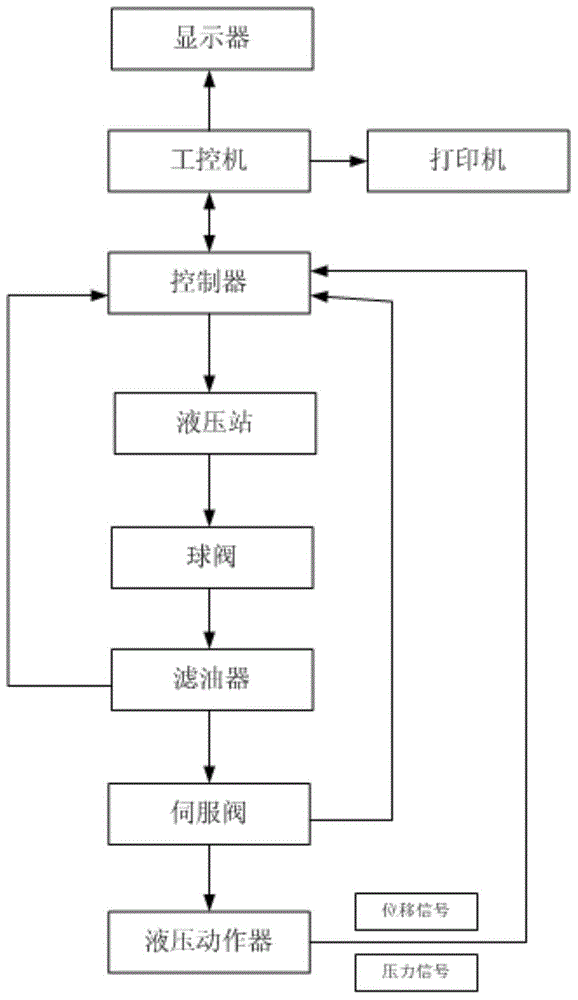

[0018] Such as figure 1 , 2 The best embodiment shown is the synchronous stretching and releasing control system for pre-tensioning track slabs, including a pedestal 1, a plurality of molds 2 on which track slabs are placed, a transverse tension beam 3, a longitudinal tension beam 4 and a hydraulic actuator 5 , the hydraulic actuator 5 is located on the inner wall of the tunnel wall outside the pedestal 1, the transverse tension beam 3 and the longitudinal tension beam 4 are respectively connected to the corresponding hydraulic actuator 5, and the pedestal 1 There are several molds 2 arranged vertically and horizontally, so that a plurality of evenly distributed longitudinal mold rows and horizontal mold rows are formed on the pedestal 1, and the track plate 6 placed on the mold 2 on each longitudinal mold row The longitudinal prestressed steel bars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com