A Tension Control Mechanism for Printing Machine Cloth

A tension control mechanism and printing machine technology, applied in printing machines, rotary printing machines, printing, etc., can solve problems affecting printing effects, etc., and achieve the effect of adjusting the tension and solving the tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

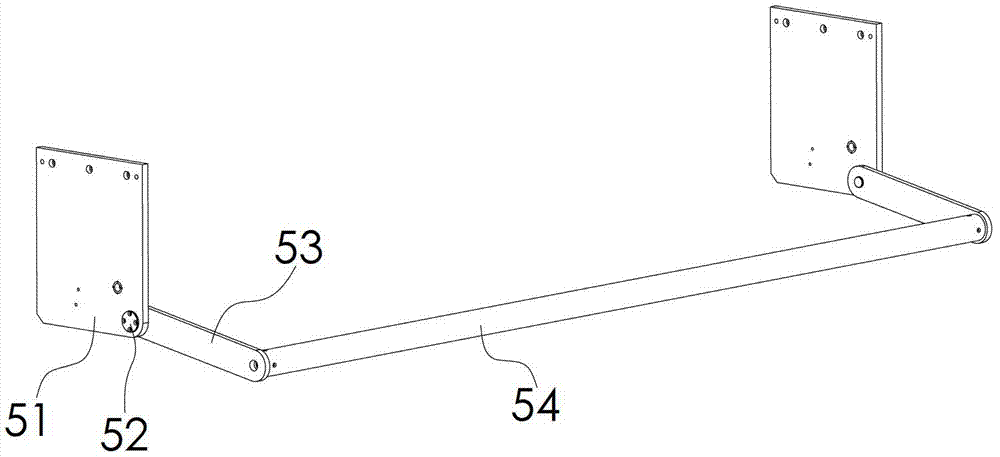

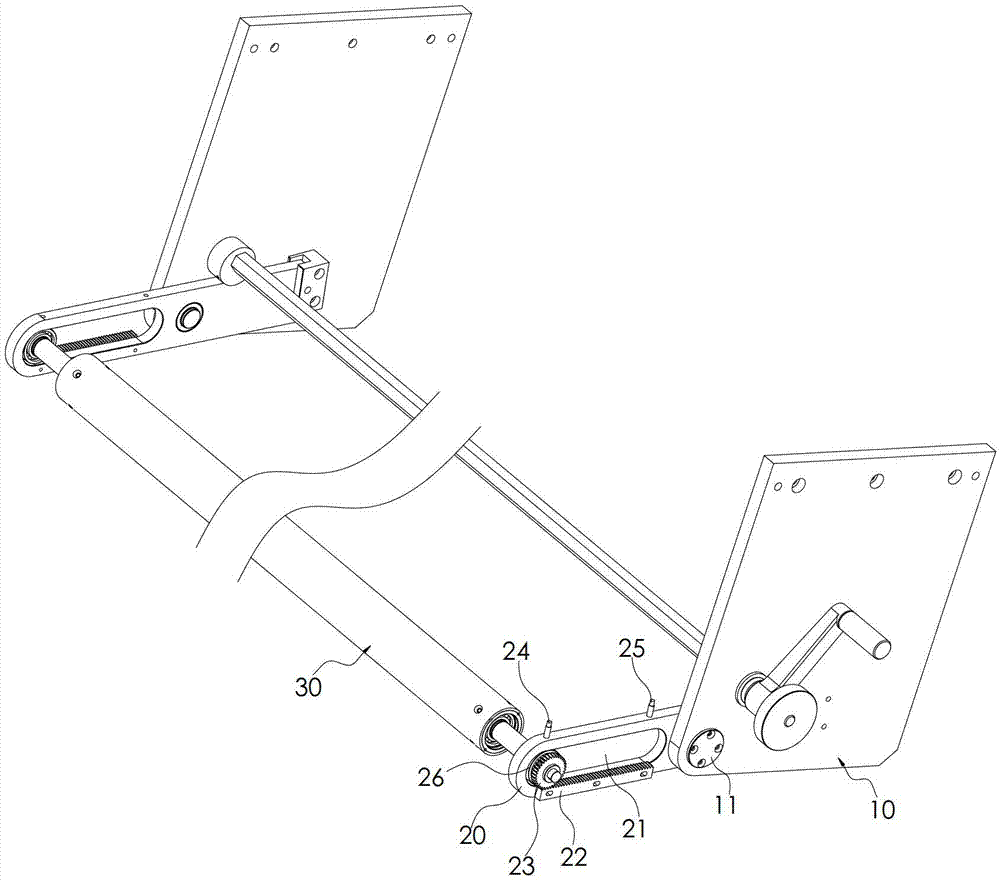

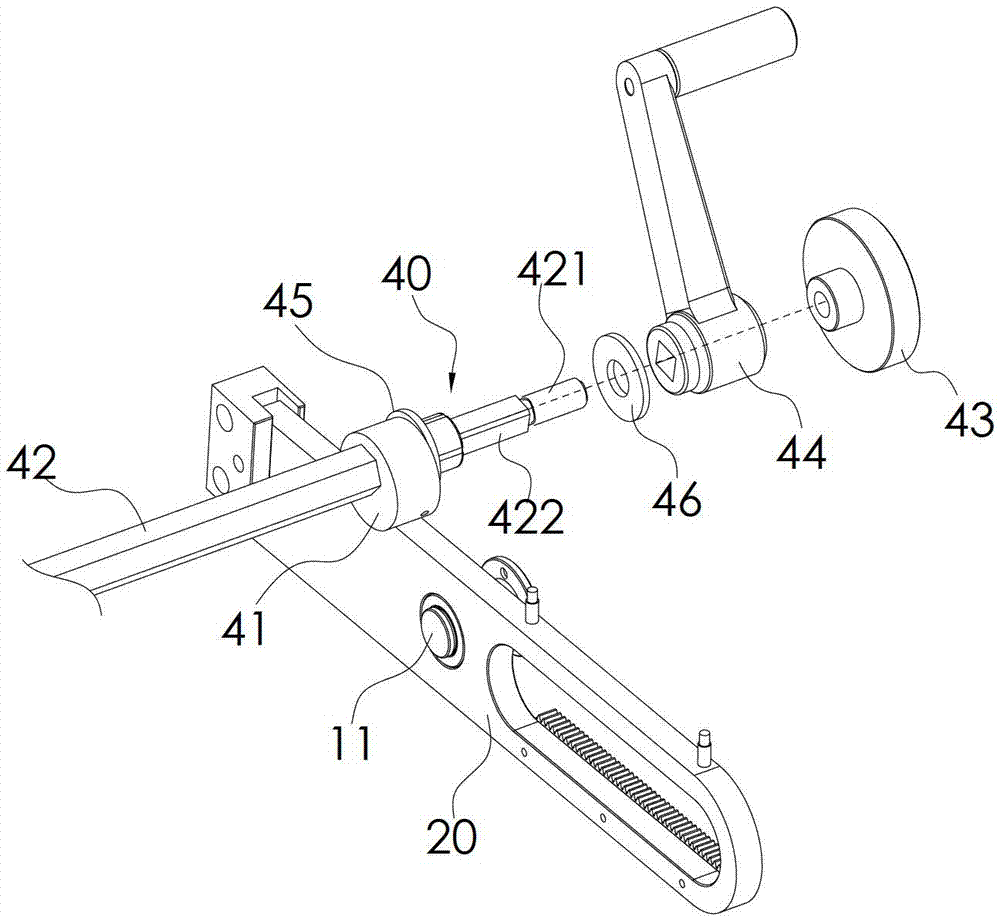

[0024] see figure 2 , 3 , 4, is the tension control mechanism of a kind of printing machine cloth of the present invention, comprises fixed plate 10, swing arm 20, tension roller assembly 30 and angle adjustment assembly 40, and fixed plate 10 is used as the installation basis of the whole mechanism, and swing arm 20 passes through A pivot 11 is pivotally connected to the fixed plate 10, and the swing arm 20 is provided with a chute 21 extending along its length direction and positioned outside the pivot 11. The chute 21 has a built-in chute 21 that can move along the length direction of the chute 21. Bearing 26, the diameter of the outer ring of the bearing 26 is equivalent to the width of the chute 21, which is limited in the chute 21 and can roll in the chute 21; the upper part of the swing arm 20 is also provided with a first limit switch 24 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com