Prestressed reinforcement reinforcing system used for dome ring beam and construction method of prestressed reinforcement reinforcing system

A technology of prestressed steel bars and prestressed tendons, which is applied to building reinforcements, processing of building materials, structural elements, etc., can solve the problems of easy deformation of the connection between dome ring beams and walls, and reduce stress and deformation, reduce Structural damage, convenient effect of making prestressed steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0032]The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0033]The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

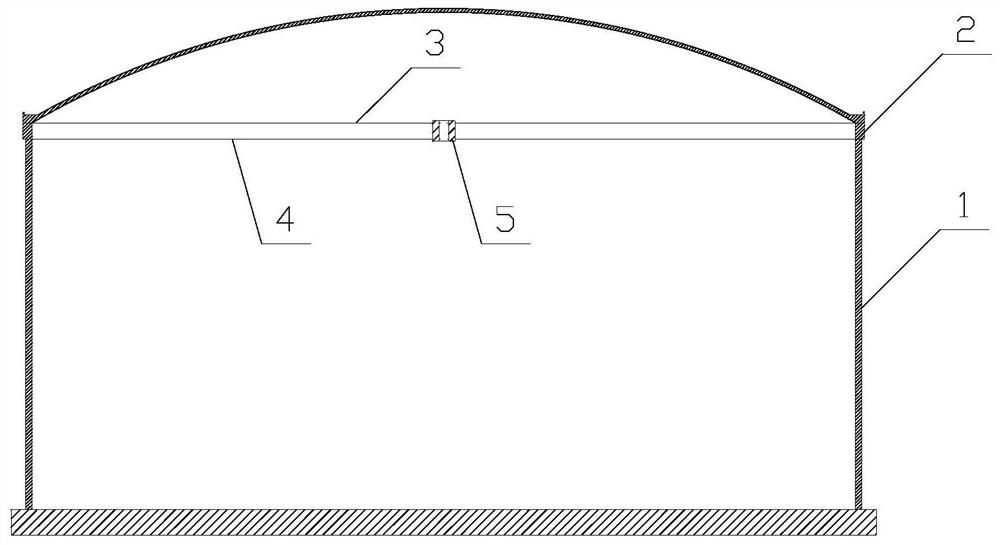

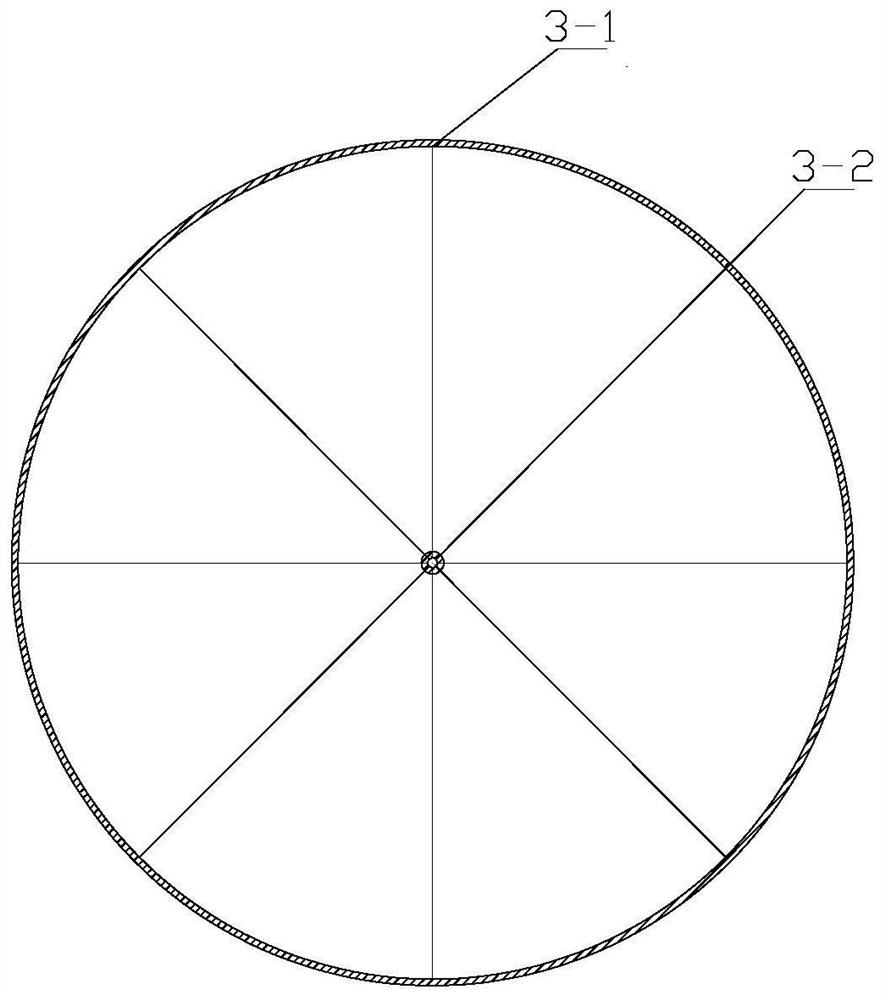

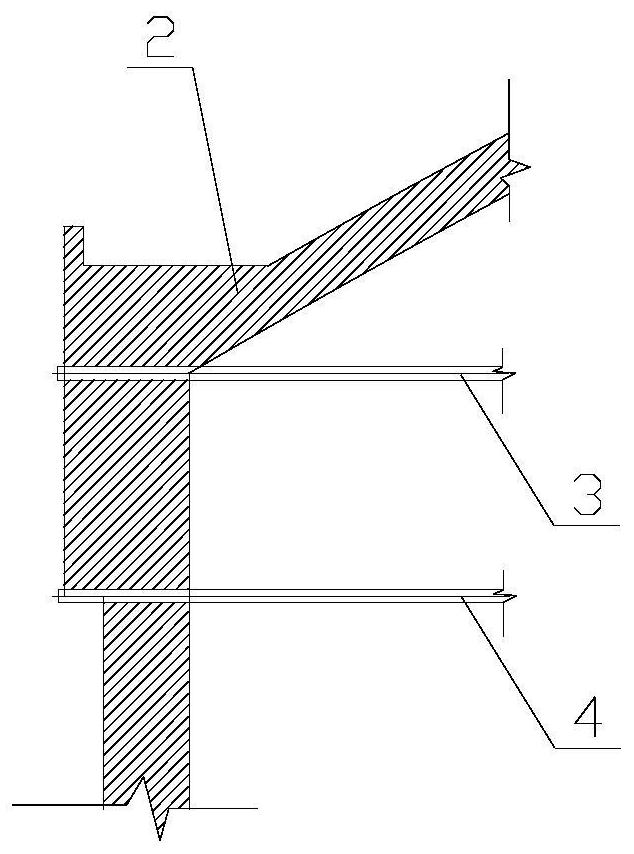

[0034]Such asfigure 1 withfigure 2 Shown is a structural schematic diagram of the prestressed steel reinforcement system for dome ring beams provided by the present invention, which is applied to the dome ring beam 2 of the outer tank of LNG storage tank, and solves the problem of the dome ring beam 2 and the wall in the outer tank of LNG storage tank. The connection of the body 1 is prone to deformation, which reduces the occurrence of concrete cracks at the connection between the dome ring beam 2 and the wall 1, thereby improving the bearing capacity of the outer tank of the LNG storage tank.

[0035]The wall 1 of the outer tank of the LNG storage tank is a closed annular wall, the wall 1 is fixed on the bearing platform, and the dome ring bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com