Anti-seismic bracket early warning system and early warning pull rod

A technology of early warning system and anti-vibration support, which is applied to pipeline supports, alarms, instruments, etc., to achieve the effects of less consumables, lower production costs, and simple adjustment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

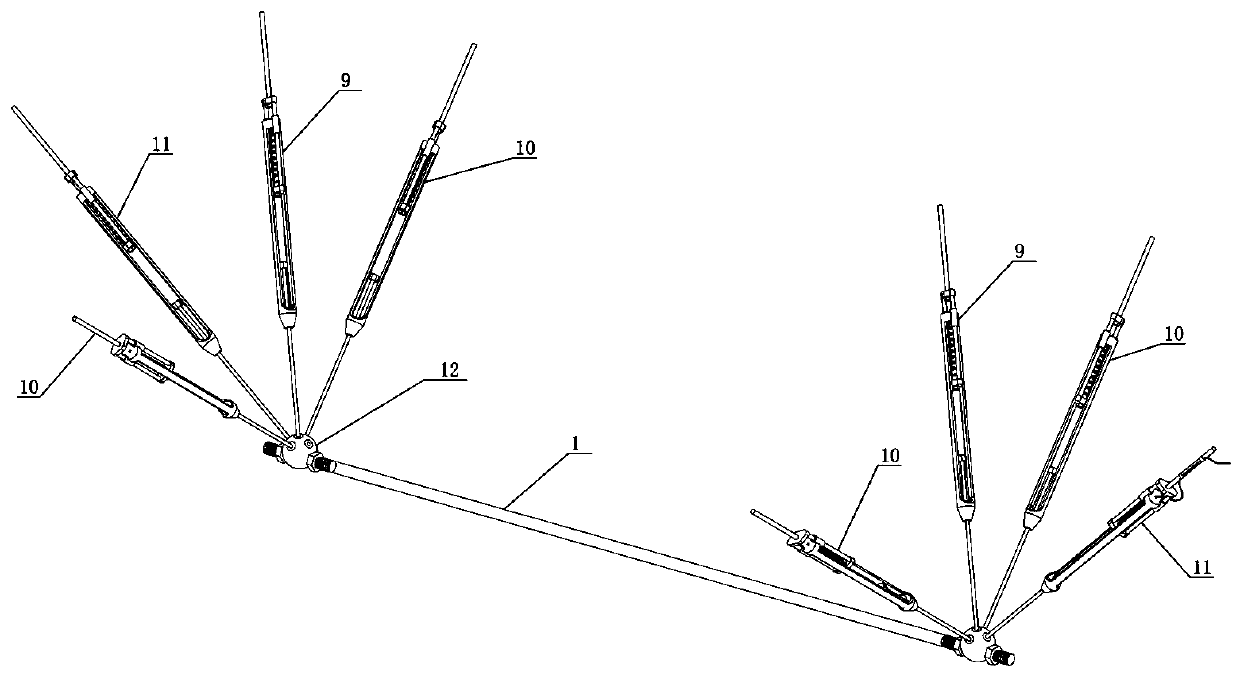

[0031] Embodiment 1: The anti-seismic support is formed by setting a multi-directional traction support on the existing pipeline hanger, and at the same time, the multi-directional traction rods are respectively designed to have axial adjustment function and elastic self-adjustment function, further in such as figure 1 A pressure sensor is added to the end of the strong spring 911 in the shown tie rod to collect the pressure change or displacement change of the key parts of the anti-seismic support, and set the threshold value of the change range, and an alarm will be issued after the threshold value is exceeded, so as to realize the early warning function of the anti-seismic support.

[0032] Such as figure 1 As shown, the traction ends located at both ends of the support beam 1 are combined spheres respectively, and the two ends of the support beam 1 are respectively installed in the threaded mounting holes 5 of the combination sphere, and the combined spheres are used to con...

Embodiment 2

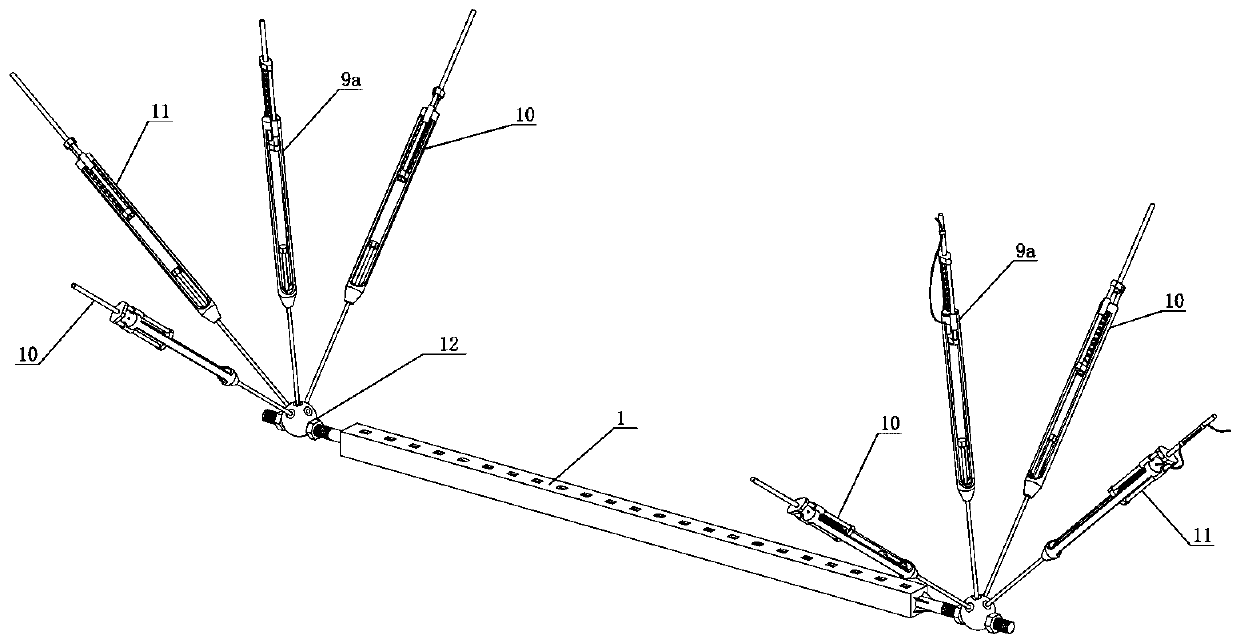

[0042] Embodiment 2: The anti-seismic support is formed by setting a multi-directional traction support on the existing pipeline hanger, and at the same time, the multi-directional traction rods are respectively designed to have axial adjustment function and elastic self-adjustment function, and further part of the rods The tension-repulsion force is applied by pushing and pulling repulsively to improve the seismic performance and stability of the whole support, such as figure 2 As shown, a pressure sensor is further added to the end of the strong spring 911 to collect the pressure change or displacement change of the key parts of the anti-seismic support, and the threshold value of the change range is set, and an alarm is issued after the threshold value is exceeded, so as to realize the early warning function of the anti-seismic support. Such as figure 2 As shown, the traction ends located at both ends of the support beam 1 are combined spheres respectively, and the two en...

Embodiment 3

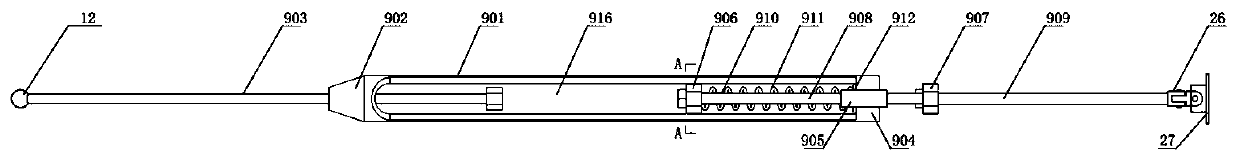

[0052] Embodiment 3: A kind of early warning rod applied to the early warning system of the anti-seismic support in embodiment 1 or 2, see image 3 and Figure 4 , Figure 6 and Figure 7 As shown, it includes a conjoined pipe, one end of the conjoined pipe is a screw sleeve 902 and the other end is a support wall 904, and the two sides of the conjoined pipe are symmetrically opened with side holes 916 to form a conjoined rod 901 connected to the screw sleeve 902 and The support wall 904 is a structure, the screw sleeve 902 is connected to the screw rod 903, and the two sides of the support wall 904 are fixedly connected with sliding sleeves 905, and the sliding sleeves 905 on both sides are respectively sleeved with sliding rods 908, and the inner sliding sleeves are sleeved in the connected pipe. Block 906, the two sides of the inner slider 906 protrude outside the side hole 916, the inner ends of the two sides of the slider 908 are respectively fixed on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com