Transmission carrier cover closure ensuring method and device

A transmission carrier and cover technology, applied in the direction of transportation and packaging, conveyors, keys, etc., can solve problems such as impact, unsmooth transmission system, falling out, etc., to increase privacy, ensure locking function, and improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0057] The method for ensuring that the transport carrier is not opened includes the following steps:

[0058] 1) Set a locking mechanism for locking the lid and barrel on the cover or barrel of the transmission carrier;

[0059] 2) Set a locking detection mechanism on the transmission carrier;

[0060] 3) Use the locking detection mechanism to detect whether the locking mechanism really locks the cover and barrel of the transmission carrier. If not, operate the locking mechanism again to lock the cover and barrel. After confirming the locked condition Next, release the transmission carrier. In the method of the present invention, while the locking mechanism is locked, the locked state is locked by the locking detection mechanism and cannot be unlocked.

[0061] In the above method, when the locking detection mechanism has a key that can be interlocked with the locking mechanism and can be unlocked, the detection method in step 3) is: whether the locking mechanism is locked ...

example 2

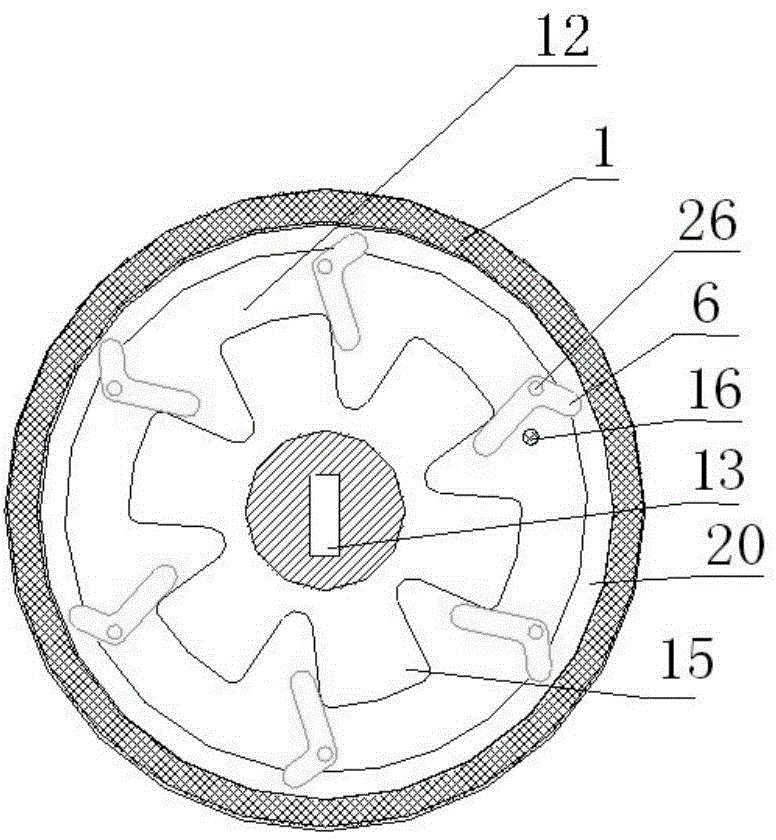

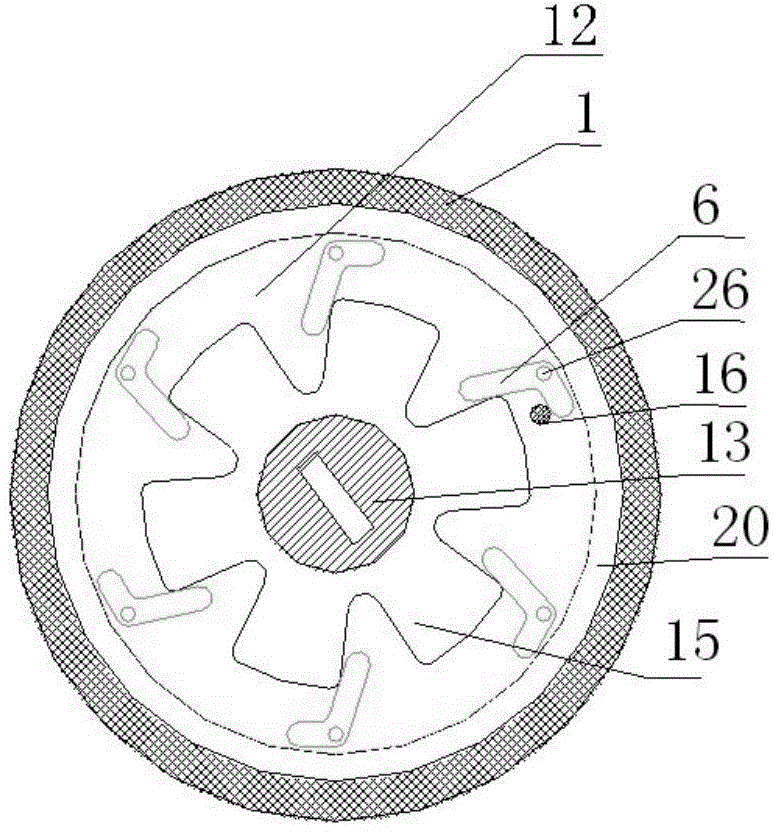

[0068] Such as figure 2 , image 3 , Figure 4 with Figure 5 As shown, the structure of the first embodiment of the device for ensuring that the transport carrier is not opened according to the present invention includes a locking mechanism and a locking detection mechanism. Wherein the locking mechanism comprises a lock core 13 arranged at the center of the cover body 12, a key 2 inserted into the lock core 13, a face plate 15 fixed outside the lock core 13, several locks connected to the cover body 12 by turning pins 26 The tongue 6 and the dead bolt limit pin 16 fixed on the cover body 12 . The barrel body 1 is provided with an annular locking groove 20 which cooperates with the locking tongue 6 . Dead bolt can be angular, also can be linear.

[0069] A through hole is provided in the cover body 12, and an outer pin 21 with the same length as the radius of the cover body is placed in the through hole, and an inner pin 22 and a spring for cooperating with the outer pi...

example 3

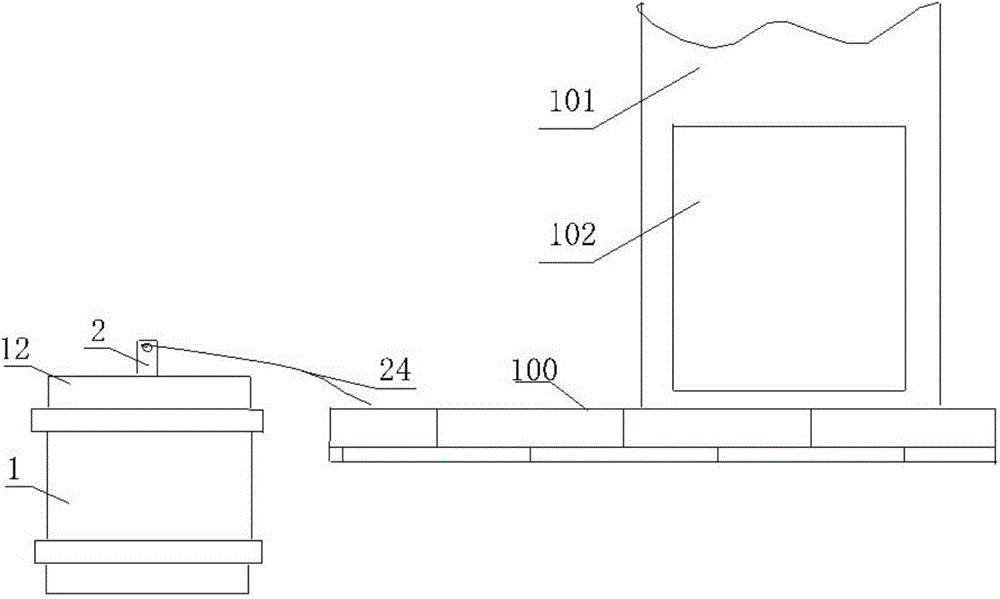

[0074] Such as Figure 7 As shown, in this embodiment, the key 2 is fixed with a handle 25 whose size is larger than the size of the entrance 102 of the delivery channel. The length of the handle 25 can be greater than the size of any direction of the entrance 102; The inlet 102 has a dimension that determines the direction. For example, entry 102 is as follows figure 1 Rectangular as shown, the length of the handle 25 only needs to be greater than the width of the inlet 102 . Other structures of this embodiment are the same as those of Embodiment 2 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com