Artificial crystalline len with transforming growth factor resistant beta2 antibody membrane on surface and manufacturing method thereof

A transforming growth factor, intraocular lens technology, applied in the direction of prosthesis, intraocular lens, medical science, etc., can solve the problems of toxic and side effects, complex manufacturing process, and short time to maintain effective concentration, and achieve the goal of inhibiting post-onset cataract, The manufacturing method is simple and reasonable, and the effect is beneficial to the recovery of vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

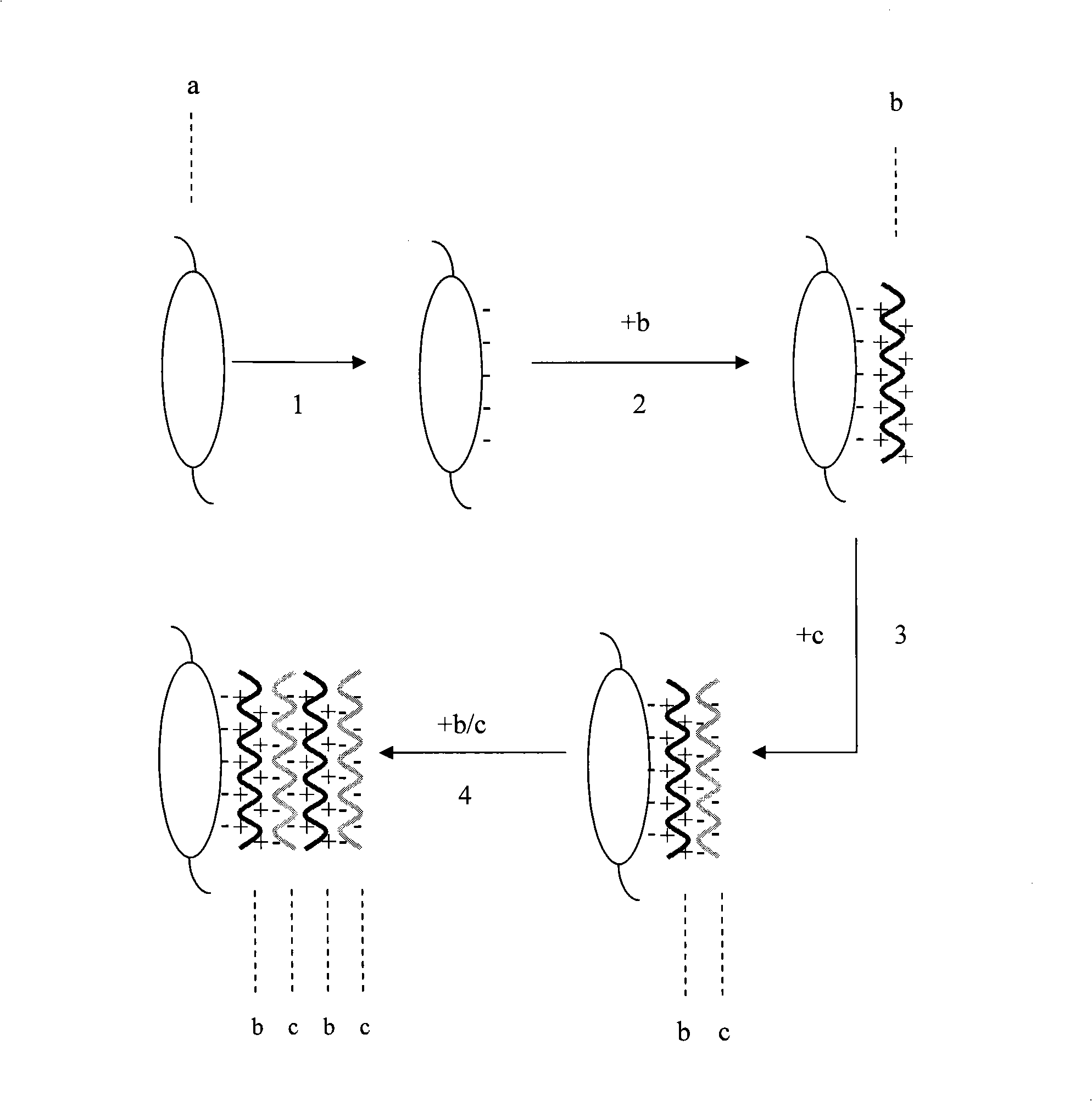

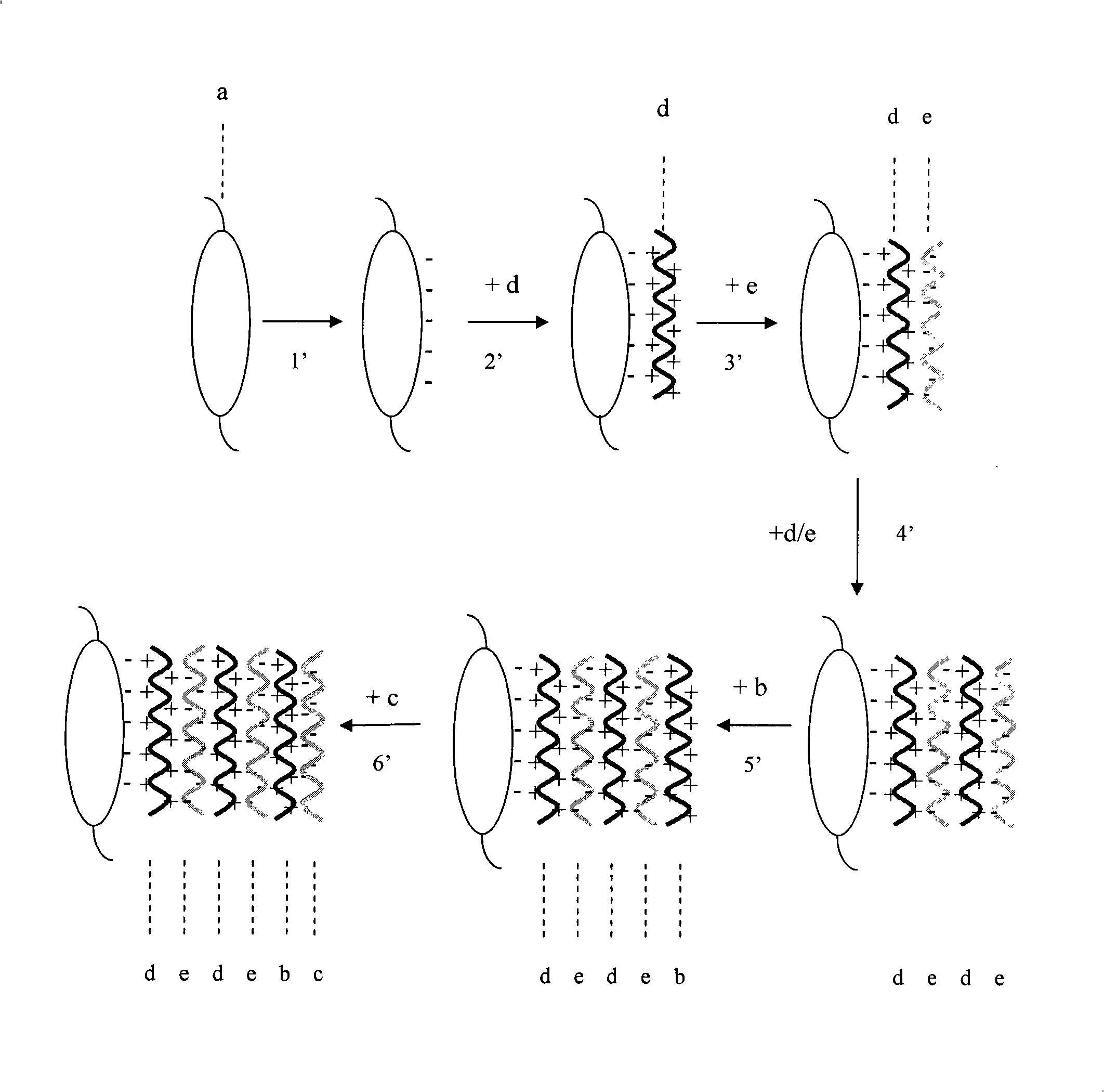

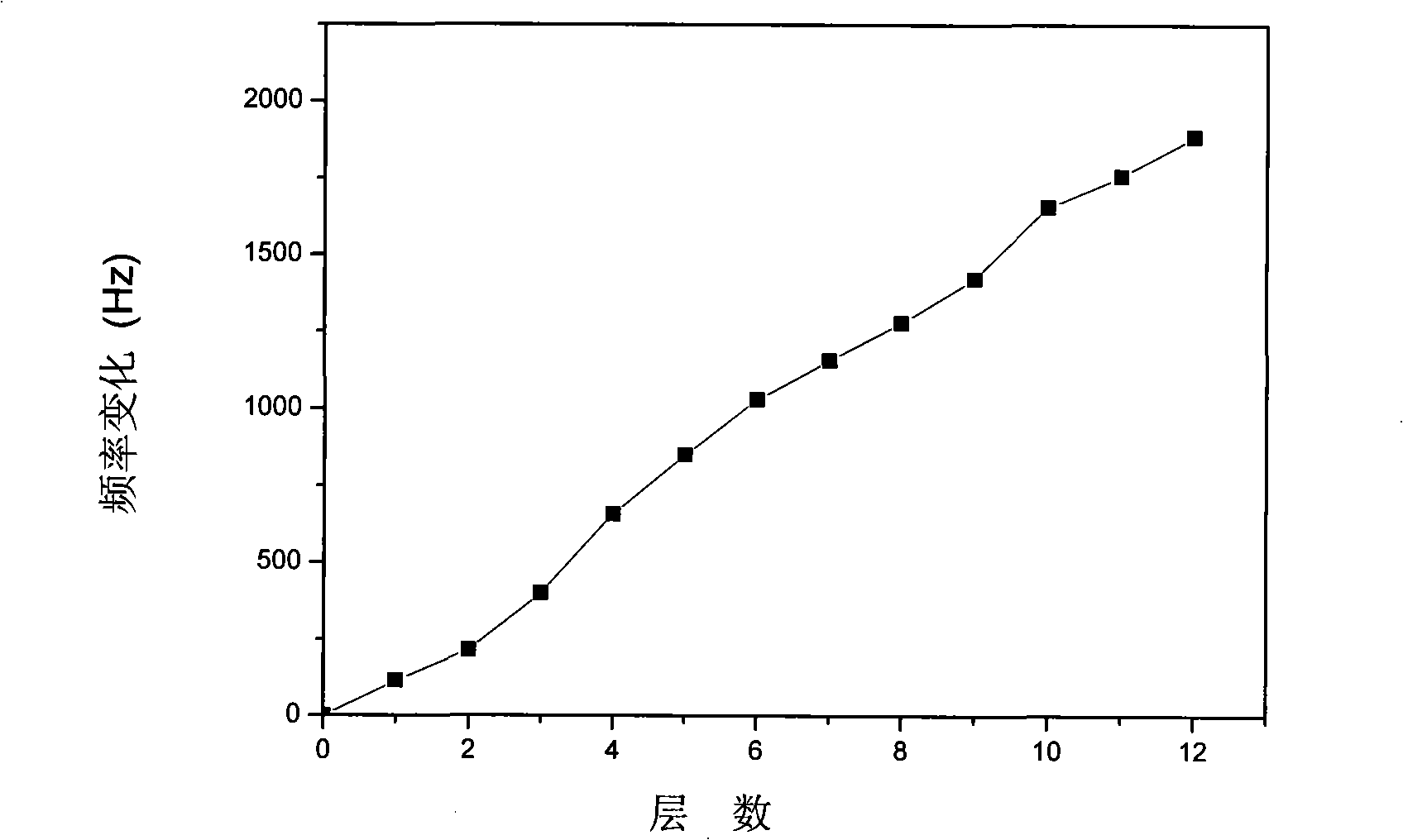

[0026] The intraocular lens with anti-transforming growth factor β2 antibody film on the surface of this embodiment is an intraocular lens with anti-transforming growth factor β2 antibody film on the surface of the optical part and loops of the intraocular lens.

[0027] The anti-transforming growth factor β2 antibody in this example is a kind of immunoglobulin, which can inhibit post-cataract through the way of immune cell biology, because the key factor causing post-cataract is transforming growth factor β2, so adopt Anti-transforming growth factor β2 antibody can inhibit the effect of transforming growth factor β2, and inhibit extracellular matrix deposition and fibrosis with its high specificity, so it can play a role that other drugs lack in fibrosis-based post-cataract. Targeting effect, and the human antibody is not immunogenic and toxic. Therefore, after the intraocular lens with anti-transforming growth factor β2 antibody film on the surface of this embodiment is impl...

Embodiment 2

[0033] The intraocular lens used in this embodiment is a kind of in polymethyl methacrylate or soft hydrophobic polyacrylate material, and the difference from Example 1 is the method for pretreatment of the surface of the intraocular lens to obtain a negative charge, and then assemble The reagents and methods used in the process are also the same as in Example 1, that is, positively charged polylysine and negatively charged anti-transforming growth factor β2 antibody. The difference with the surface pretreatment method of Example 1 is that: after the intraocular lens is cleaned and dried according to the method of Example 1, it is immersed in a 30% sodium hydroxide aqueous solution and hydrolyzed at 80°C for 30 minutes, and its surface can produce With a large number of carboxyl ions, the surface is negatively charged under aqueous conditions.

[0034] The commonality between this embodiment and Example 1 is that the surface of the intraocular lens is negatively charged after ...

Embodiment 3

[0039] Take intraocular lens, its material can be a kind of in polymethyl methacrylate, silicone gel, soft hydrophobic polyacrylate etc., be the intraocular lens of material as silicone gel, clean and bake according to the method of embodiment 1 After drying, put it into a low-temperature plasma generator, the power of the generator is 60W, the radio frequency is 13.5kHz, the gas inside is ammonia gas, the gas pressure is maintained at 50-60Pa, and the plasma glow discharge is used for 2-5 Minutes, then take out the intraocular lens, which has amino functional groups on its surface; immerse it in a hydrochloric acid solution with a concentration of 1mol / L for 30 minutes to convert the amino hydrochloride into ammonia ions, rinse with deionized water, and blow dry with nitrogen to obtain positive charged IOL surface; then immerse the above-mentioned positively charged IOL in 0.01 mg / mL negatively charged heparin aqueous solution for 120 minutes, rinse with deionized water, and b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com