Patents

Literature

32results about How to "Good water and solvent resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophilic oleophobic polymer and preparation method thereof, and application thereof in humidity response oil and water separating membrane

InactiveCN103601826AGood water and solvent resistanceLow costSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCarboxylationSewage

The invention discloses a hydrophilic oleophobic polymer and preparation method thereof, and application thereof in humidity response oil and water separating membrane. The preparation of the hydrophilic oleophobic polymer comprises the following steps: carrying out an esterification reaction of polyvinyl alcohol and perfluorocarboxylic acid or firstly carrying out a carboxylation of polyvinyl alcohol and then a neutralization reaction of the intermediate product and perfluorotertiary amine. When the product is used, a fabric silk screen is cleaned with ultrasonic sound; 10-50 parts of hydrophilic oleophobic polymer, 50-500 parts of nanometer sol, 1-5 parts of cross-linking agents and 1-5 parts of catalysts are dispersed uniformly; the mixed liquor is dip-coated or spray-coated on the surface of the membrane, and after drying and crosslinking, the humidity response super-hydrophilic and super-oleophobic oil and water separating net membrane. According to the invention, hydrophilic groups are distributed surrounding the hydrophobic chain segment on the surface of the net membrane with humidity responsiveness, and contact angle in the air of the product to water is reduced to 0 degree from more than 90 degrees, and the contact angle in air and water of the product to oil is above 150 degrees, so the product has a low adherence characteristic of droplet. The net membrane is used for separating oil and water mixture and processing oil-containing sewage.

Owner:SOUTH CHINA UNIV OF TECH

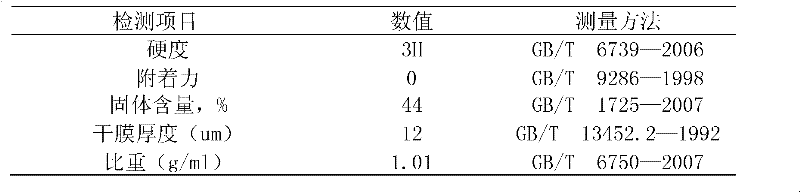

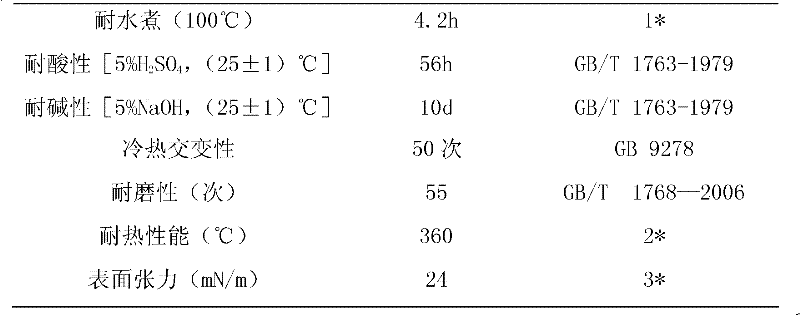

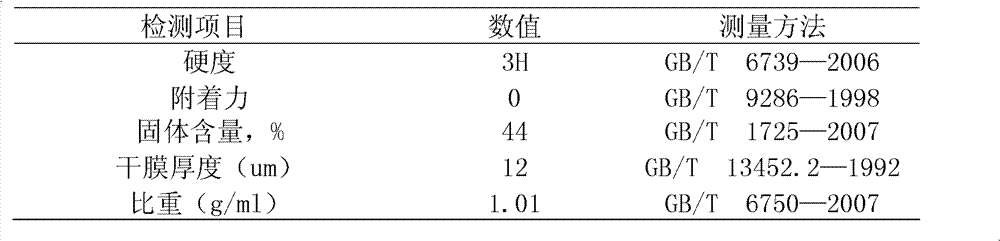

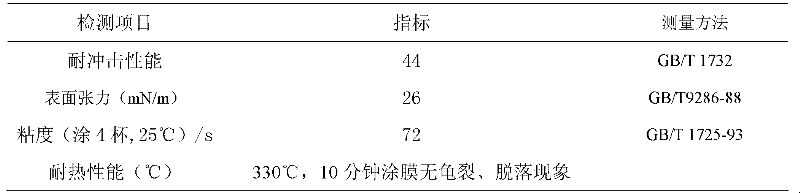

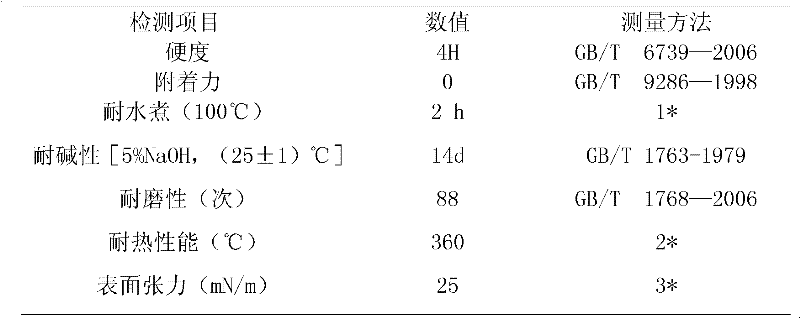

Method for preparing polyester modified organic silicon resin and coating containing the resin

ActiveCN102504265ALower surface energyLow surface energy coatings with good heat resistanceCoatingsPolyesterGlycidyl ethers

The present invention relates to a method for preparing polyester modified organic silicon resin which is prepared from 45-75 wt% of saturated polyester, 1-10 wt% of 3-glycidyl ether oxygen propyl trimethoxy silane and 20-45 wt% of organic silicon resin by reacting. The acid value of the saturated polyester is within a range of 60 to 120 mgKOH / g, and the weight-average molecular weight of the saturated polyester is within a range of 2000 to 6000. The weight-average molecular weight of an intermediate of the organic silicon resin is within a range of 800 to 2000, the content of alkoxy of the organic silicon resin is within a range of 2.5 to 15%, and the content of hydroxyl of the organic silicon resin is within a range of 3 to 20%. By combining with advantages of saturated polyester and organic silicon resin, the method has advantages of excellent heat resistant quality, good metal adhesion, low surface energy, excellent boiling resistant quality and acid-alkali resistant quality, and good temperature variation resistant quality. The polyester modified organic silicon resin prepared by the method can be used for preparing a high temperature resistant coating with low surface energy.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Polyamide thermosol for clothing and preparation method thereof

The invention discloses a polyamide hot melt adhesive used for clothing a preparation method thereof. With the protection of nitrogen-gas, an unsaturated fatty acid dimers comprising carbon numbers between 12 and 20, an dicarboxylic acid comprising carbon numbers between 6 and 12, a molecular weight regulator, a diamine, a lactam, water and a stabilizer are subject to lower temperature and pressure and dehydration in reactions, next, an N-diethylamine- propyl-Octadecanamide, a nonyl phenol, condensation products of formaldehyde and tetraethylenepentamine are added in and stirred. After the series of reactions, the polyamide hot melt adhesive is obtained. The polyamide hot melt adhesive of the invention of used for clothing has the advantages of narrow molecular weight range, rapid solidification and excellent performance of water resistance and solvent resistance, etc.; the copolyamide is modified by adding appropriate proportions of condensation products of N-diethylamine propyl-Octadecanamide and mnnnich amide, so as to improve the water resistance and solvent resistance substantially. The loss rate of peeling strength of the products obtained is less than 20 percent after alkaline cleaning above 60 DEG C; the loss rate of peeling strength of the products obtained is less than 10 percent after dry cleaning by tetrachloroethylene.

Owner:南通天洋光伏材料科技有限公司

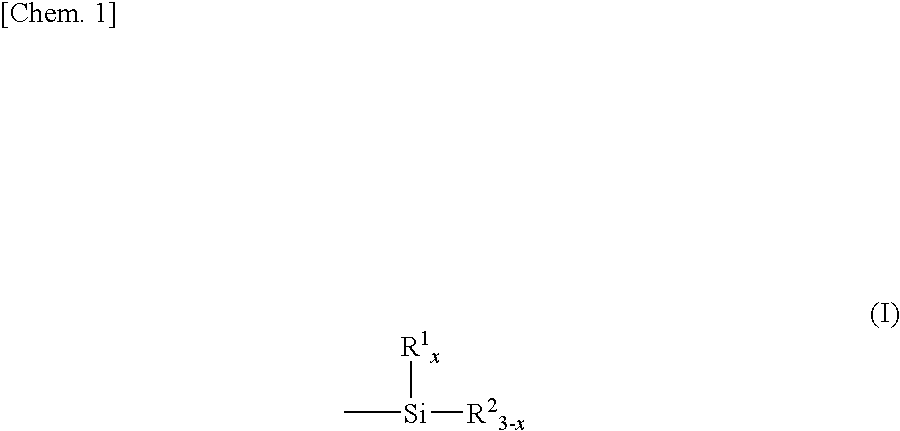

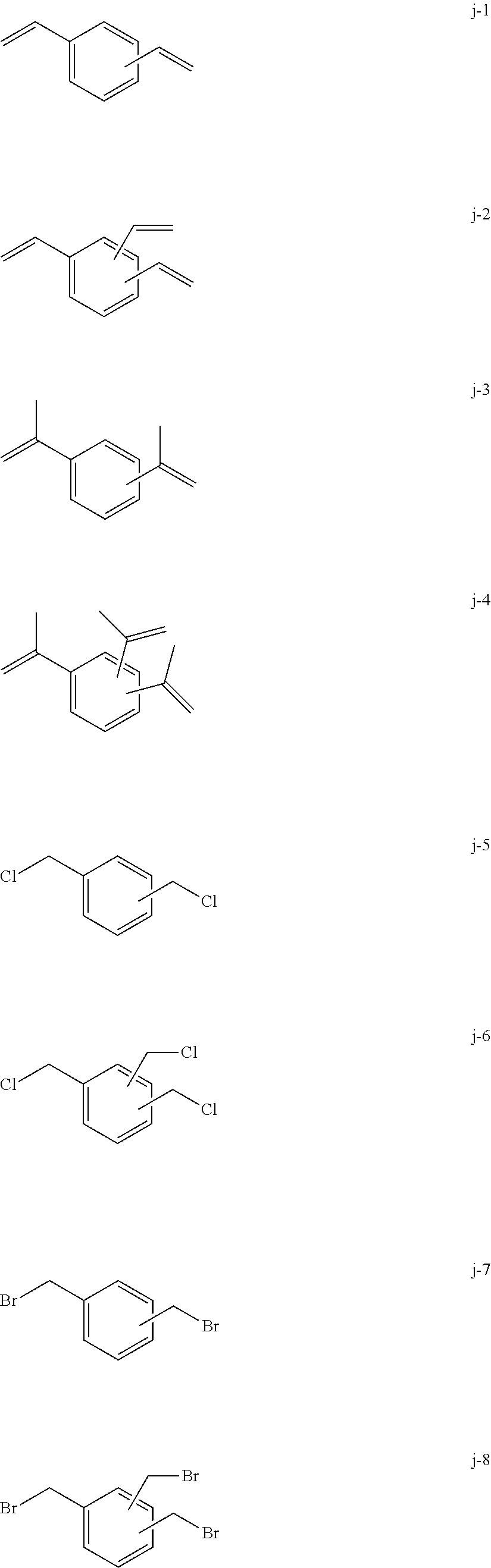

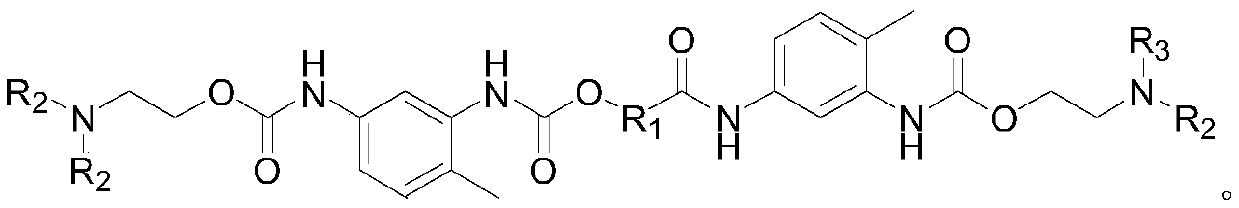

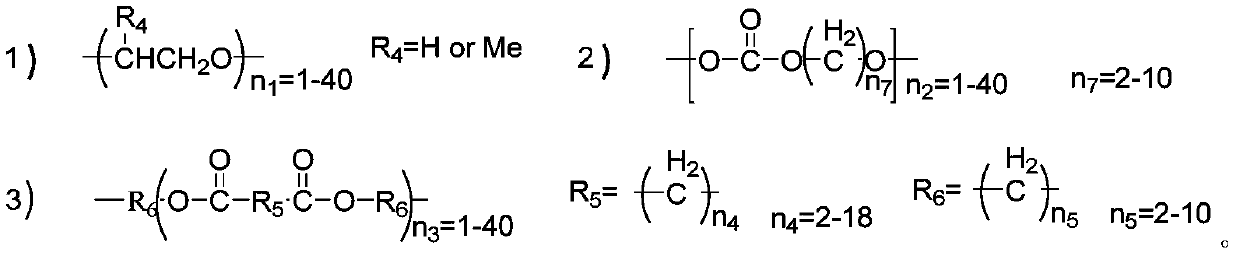

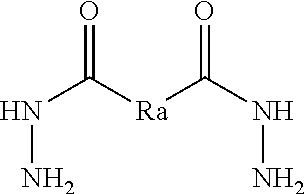

Ink composition, image forming method, and printed article

InactiveUS20130257034A1Good solvent resistanceImprove water resistanceOther printing matterInksSolubilityPolymer science

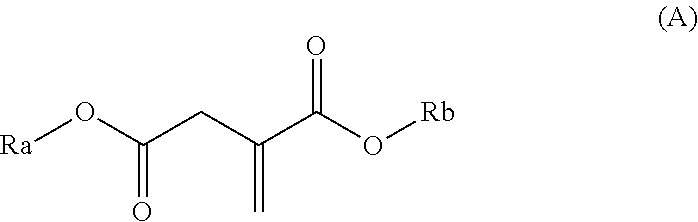

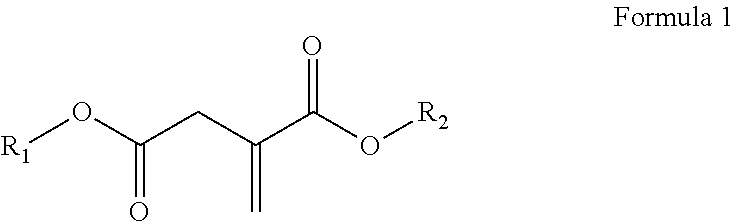

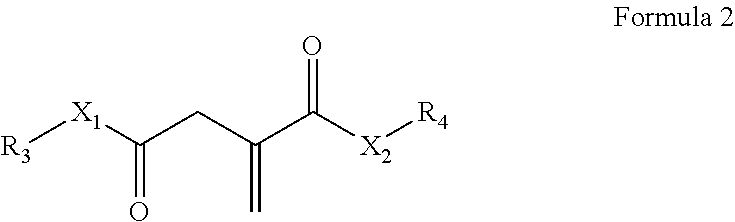

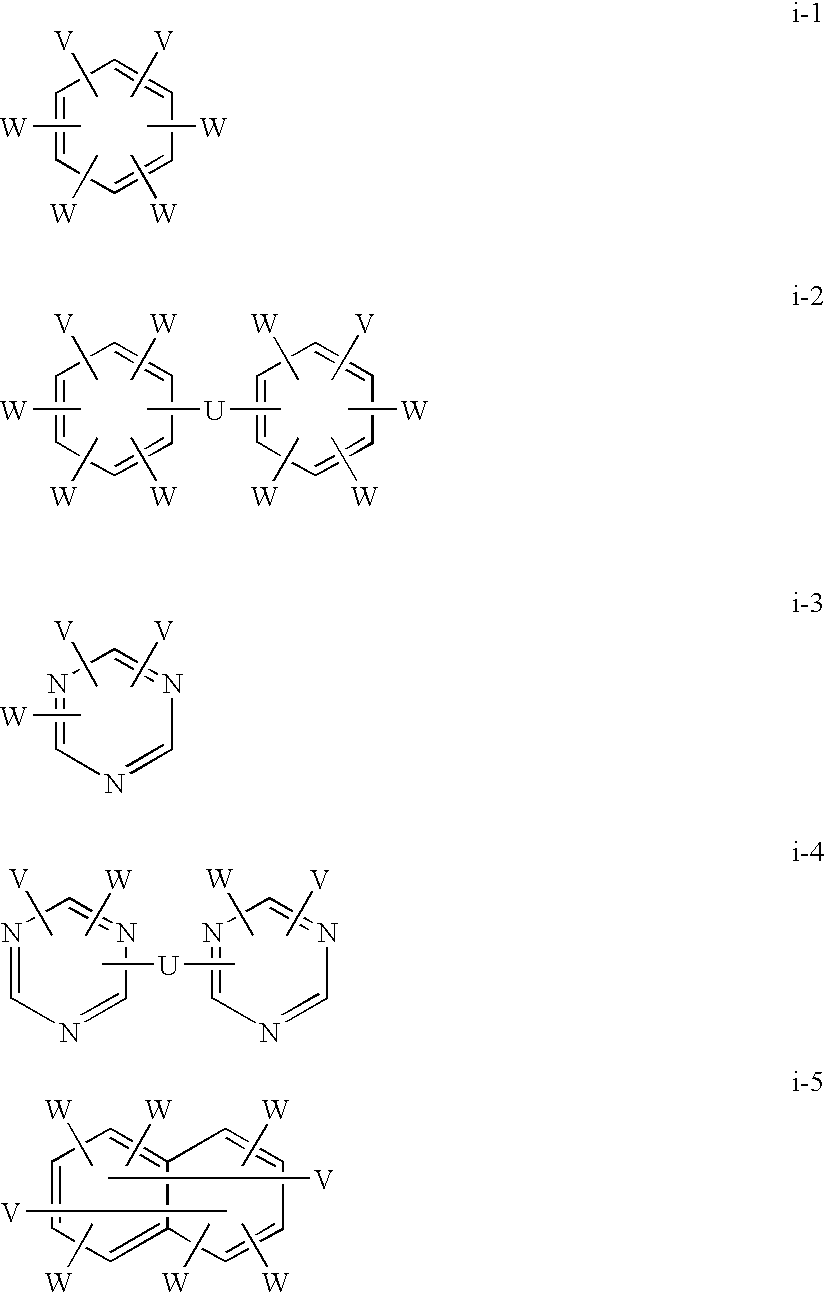

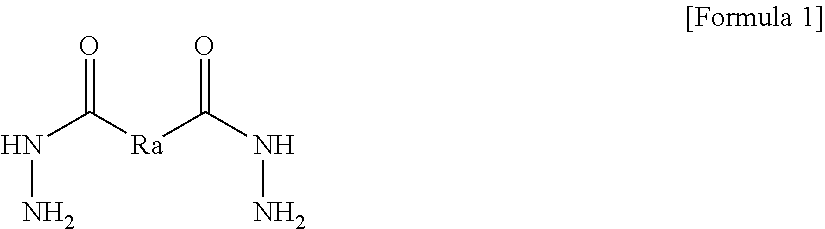

An ink composition of the present invention includes: (a) a polymer compound which includes a repeating unit (a-1) having a partial structure expressed by the following General Formula (1), a repeating unit (a-2) which has a hydrophilic group and accounts for 8% to 25% by mass with respect to the total mass of the polymer compound, and a repeating unit (a-3) having a hydrophobic group, the polymer compound having a solubility parameter in an unneutralized state of 20.7 MPa1 / 2 to 23.0 MPa1 / 2, (b) water; and (c) a water-soluble organic solvent.

Owner:FUJIFILM CORP

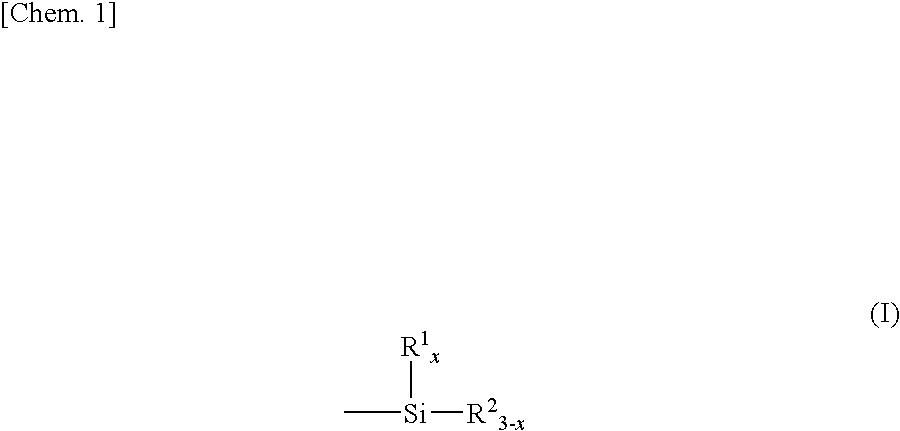

Coating agent and method for production thereof

ActiveUS20100273930A1Good chemical resistanceImprove corrosion resistancePolyurea/polyurethane coatingsAqueous mediumCore shell

Disclosed is a coating agent characterized by comprising: a core-shell-type resin particles (A) each having a shell layer and a core layer; a compound (B) having at least one selected from the group consisting of a hydrolysable silyl group and a silanol group and also having an epoxy group; and an aqueous medium, wherein the shell layer comprises (a1) a urethane resin with 2000 to 5500 mmol / kg of an aliphatic cyclic structure and at least one selected from the group consisting of a carboxyl group and a carboxylate group and the core layer comprises (a2) a vinyl polymer having a basic nitrogen-atom-containing group. Further disclosed are a coating agent for a plastic base material and a coating agent for a metallic base material.

Owner:DAINIPPON INK & CHEM INC

Water-dispersible quick-drying low-temperature self-crosslinked acrylate resin for inks and preparation method thereof

InactiveCN104262526AGuaranteed water solubilityImprove heat resistanceInksHydrophilic monomerWater dispersible

The invention discloses a water-dispersible quick-drying low-temperature self-crosslinked acrylate resin for inks and a preparation method thereof. The water-dispersible quick-drying low-temperature self-crosslinked acrylate resin for inks is prepared by copolymerizing the following components in parts by mass: 12-20 parts of hard monomer, 12-20 parts of soft monomer, 4.5-10 parts of first-type hydrophilic monomer, 0.5-2.5 parts of second-type hydrophilic monomer, 0.6-2 parts of crosslinkable monomer, 0.3-0.6 part of initiator and 50-70 parts of solvent. A pH regulator is added to regulate the pH value to 7-8; and 30-60 parts of water is added as a dispersing agent. The ink prepared by using the water-dispersible acrylate resin as the connecting material can implement low-temperature (<50 DEG C) crosslinking curing, and has the advantages of short drying and curing time (the surface drying time is 25-50 seconds), excellent adhesive force (Grade 0) on low-polarity materials (PE (polyethylene) and PP (polypropylene) films), favorable staining power, favorable bonding resistance, favorable water resistance and favorable solvent resistance.

Owner:SOUTH CHINA UNIV OF TECH

Use of a polymer composition

InactiveUS20150010863A1Good water and solvent resistanceHigh hardnessCosmetic preparationsToilet preparationsWaxPersonal care

Owner:DSM IP ASSETS BV

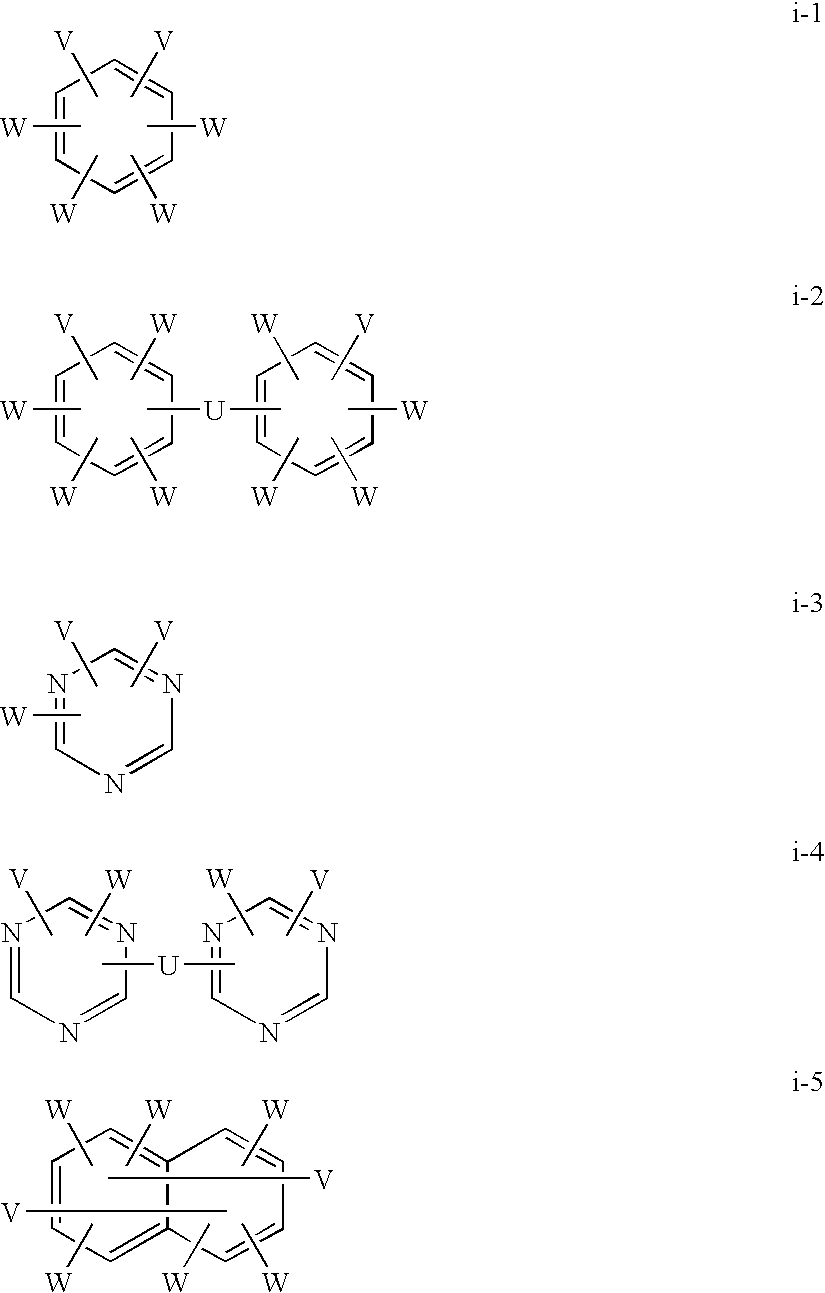

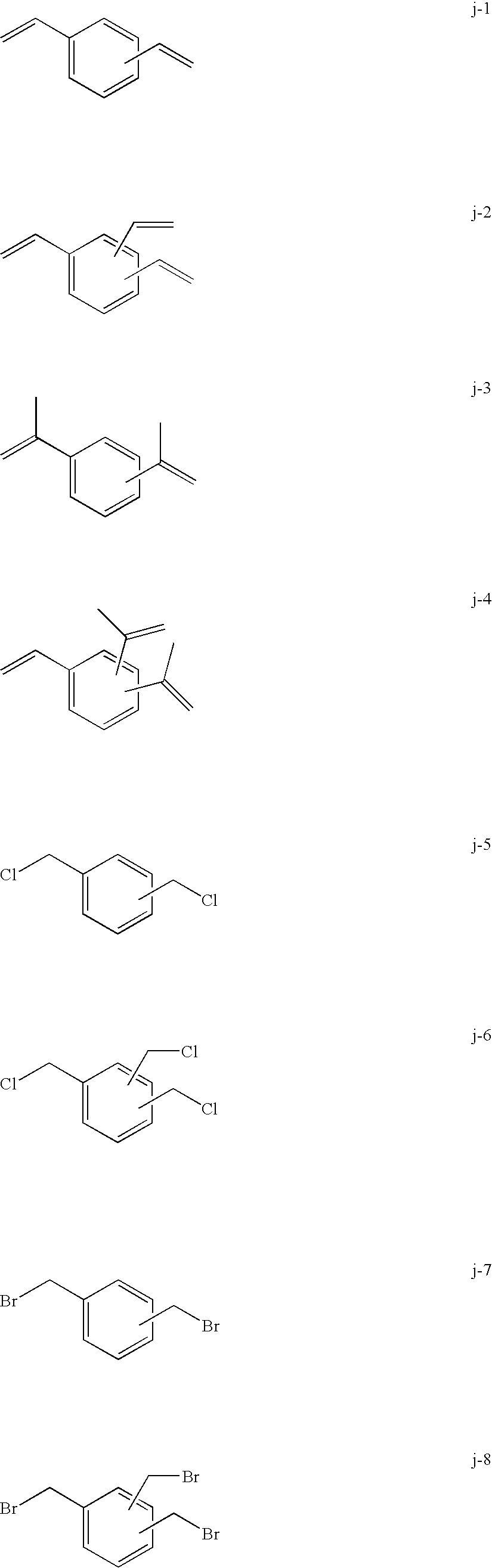

Crosslinked polymer electrolyte and method for producing same

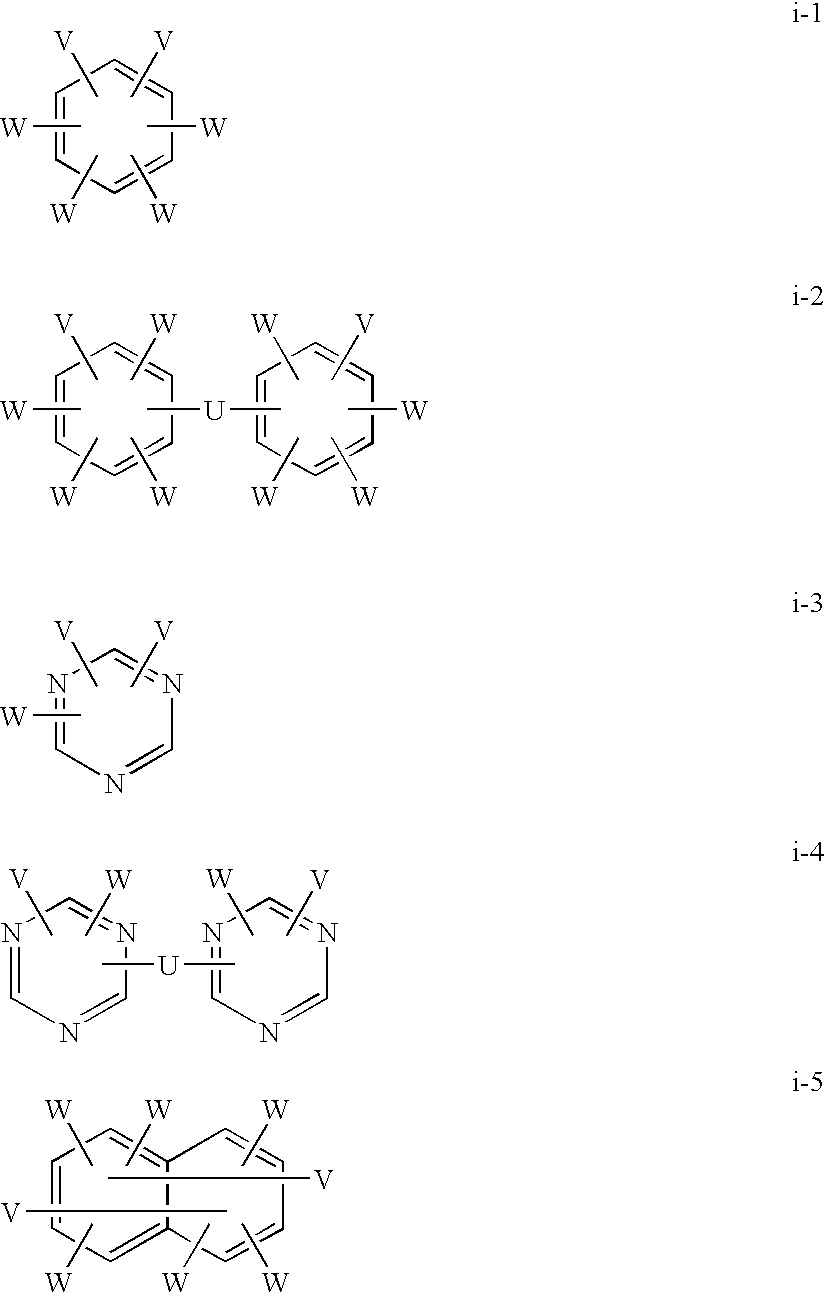

InactiveUS8211558B2Good water and solvent resistanceImprove heat resistanceSolid electrolytesCation exchanger materialsIon exchangeSolvent

There are provided a new crosslinked polymer electrolyte excellent in water resistance and solvent resistance, high in heat resistance, inexpensive and low in methanol permeability, and suitable for the proton conductive membrane of a fuel cell, by means of the crosslinked polymer electrolyte obtained by the following (1) or (2), and its production method.(1) A compound having two or three or more reactive groups is reacted with a polymer electrolyte.(2) A compound having two or three or more reactive groups is reacted with a polymer to obtain a crosslinked polymer and then an ion exchange group is introduced into the resultant polymer.

Owner:SUMITOMO CHEM CO LTD

High-strength cellulose/lignin composite material with reinforced concrete structure and preparation method thereof

ActiveCN107042559ASimple preparation processImprove efficiencyWood treatment detailsWood impregnation detailsCelluloseAlcohol

The invention discloses a high-strength cellulose / lignin composite material with a reinforced concrete structure and a preparation method thereof. The preparation method comprises the following steps that (1) a timber is cut into a wood chip in a needed specific shape; (2) the wood chip is soaked in a reaction kettle containing sodium sulfite, sodium hydroxide and methyl alcohol cooking liquid to be cooked; and (3) the cooked wood chip is washed with clean water, residual cooking liquid is removed, pressurization and drying are conducted, and the high-strength cellulose / lignin composite material with the reinforced concrete structure is obtained. The composite material has the reinforced concrete structure, and the tensile strength is as high as 810 MPa and is twenty times that of an original wood chip. The preparation method is simple in process, any non-biodegradable substances and environmentally harmful substances do not need to be added in the preparation process, and the preparation method is high in efficiency and environmentally friendly.

Owner:SOUTH CHINA UNIV OF TECH

Polymer particle, polymer dispersion, method for producing said polymer dispersion, coating material produced from said polymer dispersion, and coated article

ActiveUS20150376390A1Excellent characteristicsImprove stabilityPolyurea/polyurethane coatingsPolymer scienceN dimethylformamide

The present invention relates to: a polymer particle in which a urethane resin (A1) and an acrylic polymer (B1) are included in a single particle, said polymer particle having a gel fraction of 10% or more as measured using N,N-dimethylformamide (DMF) as a solvent; a polymer particle in which a urethane resin (A2) having a sulfonic acid group and an acrylic polymer (B2) are included in a single particle, said polymer particle having a surface acid value of 0.1 to 19 mgKOH / g as measured by a potentiometric titration method; and a method for producing a polymer dispersion. According to the present invention, it becomes possible to provide: a polymer dispersion which has excellent polymerization stability and can have an excellent coating viscosity property and excellent storage stability when used in a coating material; a method for producing the polymer dispersion; and a polymer particle contained in the polymer dispersion. It also becomes possible to provide: a coating material which enables the formation of a coating film that can have excellent water resistance and solvent resistance even when the drying conditions include a low temperature and a shorter drying time; and a coated material which has the coating material applied thereon.

Owner:MITSUBISHI CHEM CORP +1

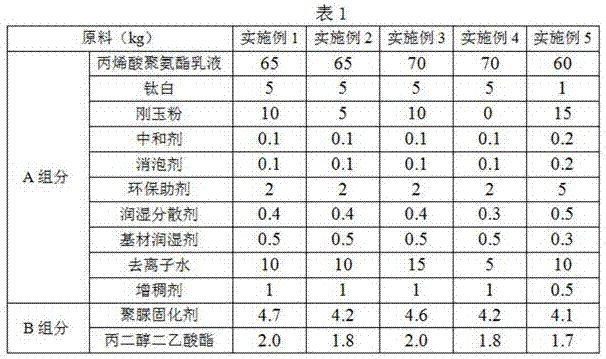

Water-based industrial fence paint

InactiveCN107142004ASmall smellImprove wear resistancePolyurea/polyurethane coatingsWater basedEmulsion

The invention relates to the technical field of water-based coating and discloses a water-based industrial fence paint which is prepared from acrylic polyurethane emulsion and a polyurea curing agent matched with corundum powder and other additives. The water-based industrial fence paint has excellent adhesion and impact resistance and good hardness, and has a certain self-cleaning function and high construction drying speed.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Crosslinked polymer electrolyte and method for producing same

InactiveUS20090274943A1Good solvent resistanceImprove water resistanceSolid electrolytesCation exchanger materialsIon exchangeSolvent

There are provided a new crosslinked polymer electrolyte excellent in water resistance and solvent resistance, high in heat resistance, inexpensive and low in methanol permeability, and suitable for the proton conductive membrane of a fuel cell, by means of the crosslinked polymer electrolyte obtained by the following (1) or (2), and its production method.(1) A compound having two or three or more reactive groups is reacted with a polymer electrolyte.(2) A compound having two or three or more reactive groups is reacted with a polymer to obtain a crosslinked polymer and then an ion exchange group is introduced into the resultant polymer.

Owner:SUMITOMO CHEM CO LTD

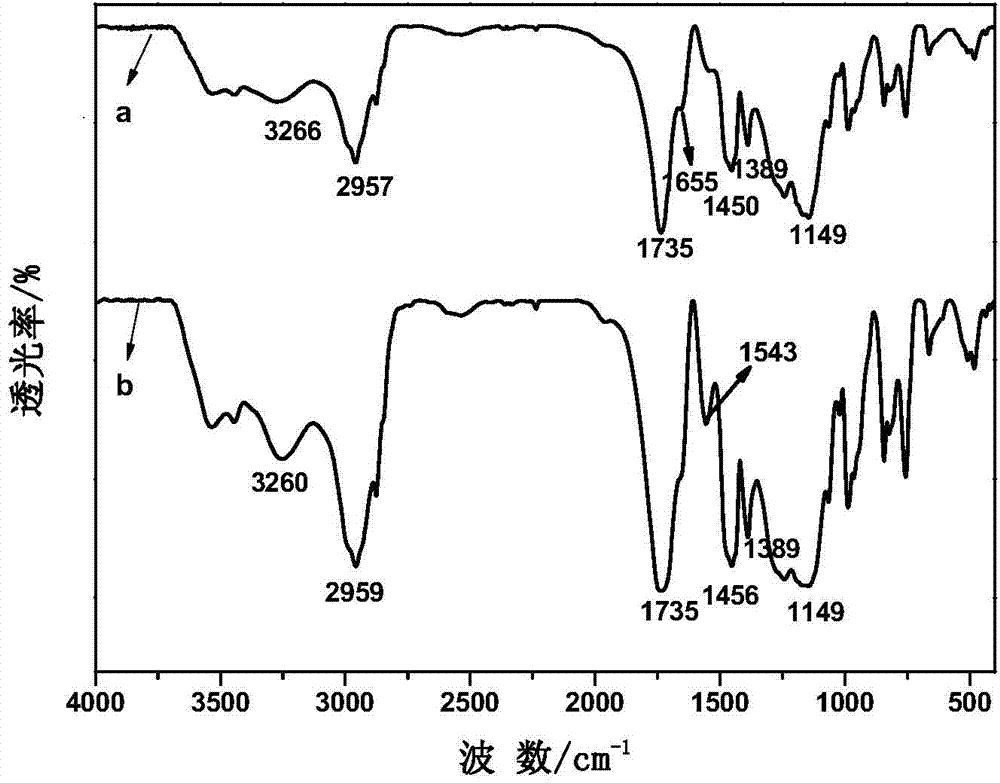

Water-based UV resin and preparation method thereof

ActiveCN111410732AHigh solid contentGood water and solvent resistancePolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention relates to the technical field of high polymer materials, in particular to water-based UV resin and a preparation method thereof. The preparation method comprises the following steps: (1) adding metered diisocyanate into a reactor, dropwise adding dehydrated polyol, and reacting for 1-3 hours to obtain a product A; (2) in another reactor, under the protection of nitrogen, adding a raw material ethanolamine, then adding a catalyst, and raising the temperature of the system to 60-80 DEG C; dropwise adding a reaction monomer, and reacting for 3-8 hours to obtain a product B; and (3)adding the product B into the reactor under the protection of nitrogen, heating the system to 60-80 DEG C, dropwise adding the product A, reacting for 1-3 hours, and discharging to obtain the water-based UV resin. The obtained water-based UV resin has high solid content and excellent water resistance and solvent resistance, and does not use a low-molecular-weight reactive diluent, so that the contradiction that high hardness and high flexibility of light-cured resin cannot be considered at the same time is overcome, and the water-based UV resin has excellent steel wool scraping resistance.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

Water-based composite resin composition and an article comprising the same

ActiveUS8945711B2Good water and solvent resistanceIncrease resistanceSynthetic resin layered productsCellulosic plastic layered productsEpoxyWater based

Owner:DIC CORPORATION

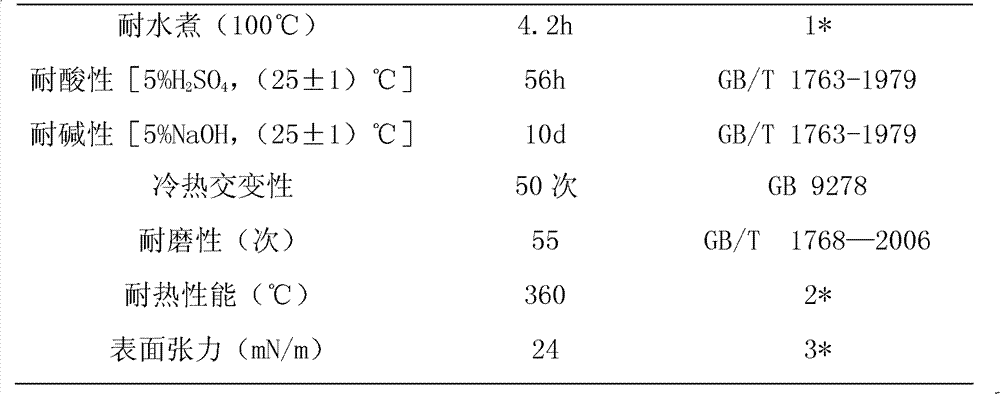

Solvent-free environment-friendly high-performance modified epoxy adhesive material and preparation method thereof

InactiveCN109943269ALow toxicityIncreased toxicityNon-macromolecular adhesive additivesMacromolecular adhesive additivesSolvent freeSolvent

The invention relates to a solvent-free environment-friendly high-performance modified epoxy adhesive material and a preparation method thereof. The material comprises a first composition, a second composition and a third composition, wherein the first composition is prepared from the following raw material components in parts by weight: 100 parts of liquid epoxy resin and 10-100 parts of hyperbranched polymer; the second composition is prepared from the following raw material components in parts by weight: 7-50 parts of compound curing agent; and the third composition is prepared from the following raw material components in parts by weight: 10-200 parts of solid filler and pigment; and the compositions are respectively packaged independently. The modified epoxy adhesive material has thecement adhesion strength of more than or equal to 5MPa and elongation at break of more than or equal to 30 percent, has excellent comprehensive performance, is easily available in raw materials, environment friendly and solvent free, and can be used in waterproof protection and reinforcement of various floor and wall faces indoors and outdoors, structure reinforcement of various constructions andthe like.

Owner:重庆东吴道路工程有限公司

Preparation method of water-based fluorine-containing acrylic emulsion

InactiveCN110951001AHigh gloss fullnessGood weather resistanceAntifouling/underwater paintsPaints with biocidesWeather resistanceAcrylic resin

The invention discloses a preparation method of a water-based fluorine-containing acrylic emulsion, which comprises the following steps: 1) in a reaction kettle, uniformly mixing and dissolving alkali-soluble solid acrylic resin, deionized water, a reactive emulsifier and an alkaline substance at 60-70 DEG C to prepare a protective colloid solution; (2) preparing an emulsion A, and (3) preparing the water-based fluorine-containing acrylic emulsion. The water-based fluorine-containing acrylic emulsion has the characteristics of high glossiness and fullness, good water resistance and solvent resistance, high weather resistance, excellent stain resistance, outstanding hydrophobicity and lipophobicity, high film forming efficiency and good product performance stability.

Owner:江苏智泰科技发展有限公司

Optical film having excellent water resistance and solvent resistance, and polarization plate comprising same

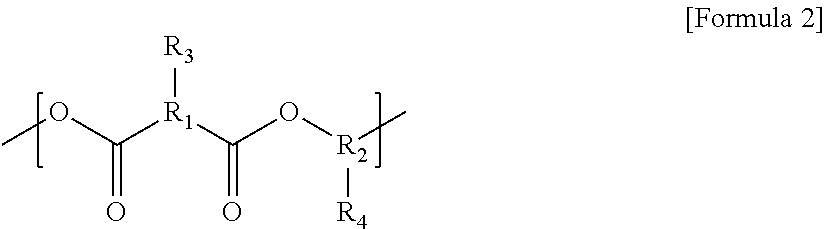

ActiveUS20170101517A1Good water and solvent resistanceGood solvent resistanceSynthetic resin layered productsPolarising elementsWater dispersiblePolymer resin

Disclosed are an optical film, including: a transparent film, and a coating layer on at least one surface of the transparent film, in which the coating layer is formed using a composition including a polymer resin, a dihydrazide-based crosslinking agent, and water-dispersible fine particles, and a polarizing plate including the same.

Owner:ANHUI HEMEI MATERIALS TECH CO LTD

Water-based composite resin composition and an article comprising the same

ActiveUS20140079944A1Good solvent resistanceImprove water resistanceLayered productsThin material handlingEpoxyPolymer science

It is an object of the present invention to provide a water-based composite resin composition which has an excellent long-term storage stability and which enables formation of a coating film having an excellent water resistance and solvent resistance. The present invention relates to a water-based composite resin composition and a coating agent; the water-based composite resin composition containing composite resin particles (A) and an aqueous medium (B), the composite resin particles (A) containing polyester resin (a1) particles having a sulfonate group and an epoxy resin (a2) of which some or all parts are encapsulated in the polyester resin (a1) particles, wherein a mass ratio [(a1) / (a2)] of the polyester resin (a1) to the epoxy resin (a2) in the composite resin particles (A) is in the range of 95 / 5 to 30 / 70.

Owner:DAINIPPON INK & CHEM INC

Coating agent and method for production thereof

ActiveUS8829080B2Increase resistanceImprove adhesionPolyurea/polyurethane coatingsPolymer scienceSilylene

Disclosed is a coating agent characterized by comprising: a core-shell-type resin particles (A) each having a shell layer and a core layer; a compound (B) having at least one selected from the group consisting of a hydrolysable silyl group and a silanol group and also having an epoxy group; and an aqueous medium, wherein the shell layer comprises (a1) a urethane resin with 2000 to 5500 mmol / kg of an aliphatic cyclic structure and at least one selected from the group consisting of a carboxyl group and a carboxylate group and the core layer comprises (a2) a vinyl polymer having a basic nitrogen-atom-containing group. Further disclosed are a coating agent for a plastic base material and a coating agent for a metallic base material.

Owner:DAINIPPON INK & CHEM INC

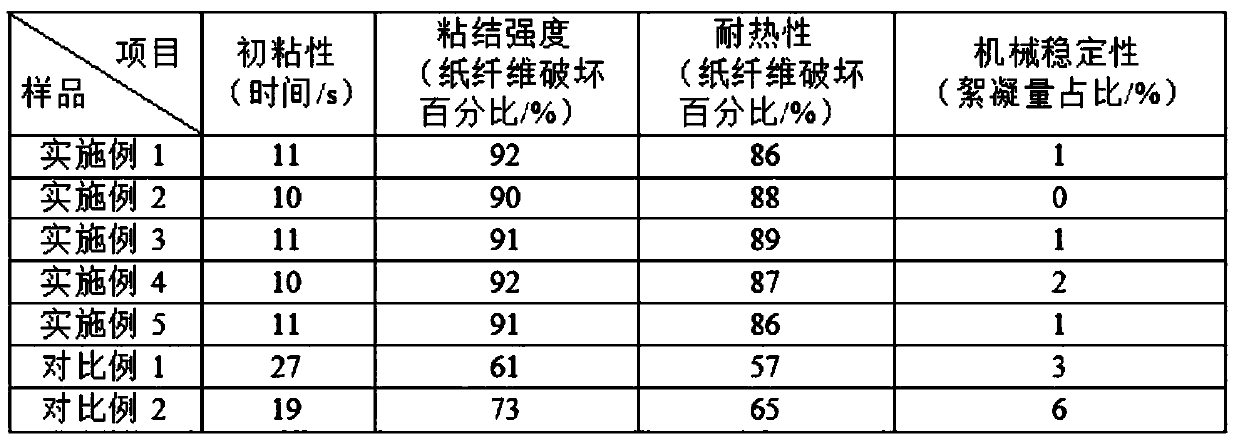

Environment-friendly water-based high-viscosity box pasting glue and preparation method thereof

InactiveCN110128973AHigh bonding strengthGood water and solvent resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedEpoxy

The invention discloses environment-friendly water-based high-viscosity box pasting glue and a preparation method thereof. The environment-friendly water-based high-viscosity box pasting glue comprises the following components: an ethylene-1-octylene copolymer emulsion, a thickening agent, a curing agent, filler, a defoaming agent, an environment-friendly plasticizer, tackifying resin and water-based polyurethane-epoxy resin-acrylate composite resin. The preparation method comprises the following steps: feeding the components into a dispersion kettle, and stirring and dispersing all the components to obtain the environment-friendly water-based high-viscosity box pasting glue. The ethylene-1-octylene copolymer emulsion in the box pasting glue is high in bonding strength and outstanding in tensile strength and tearing strength; the molecular structure of the waterborne polyurethane-epoxy resin-acrylate composite resin is net-shaped, and the waterborne polyurethane-epoxy resin-acrylate composite resin is matched with other components, so that the box pasting adhesive has relatively high bonding strength, excellent water resistance and solvent resistance and storage stability. Experimental results show that the product has good initial viscosity, bonding strength, heat resistance and mechanical stability.

Owner:江苏美乔科技有限公司

High-resistance environment-friendly water-based coating for inner wall of packaging barrel and preparation method

The invention discloses a preparation method of a high-resistance environment-friendly water-based coating for the inner wall of a packaging barrel. The preparation method comprises the steps of S1, modifying epoxy resin; S2, dispersing and grinding the powder; and S3, neutralizing and compounding. The invention further discloses the high-resistance environment-friendly water-based coating for theinner wall of the packaging barrel, which is prepared according to the preparation method of the high-resistance environment-friendly water-based coating for the inner wall of the packaging barrel. The high-resistance environment-friendly water-based coating for the inner wall of the packaging barrel disclosed by the invention is good in comprehensive performance, excellent in resistance, wear resistance, water resistance, solvent resistance and chemical stability, and strong in adhesive force with a base material.

Owner:SUZHOU SANXIN PACKAGING MATERIAL TECH CO LTD

High water resistance, toluene resistance limonene-based polyurethane and preparation method thereof

ActiveCN106519159BImprove mechanical propertiesGood solvent resistancePolyurea/polyurethane coatingsDouble bondTwo step

The invention discloses a limonene-based polyurethane with high water resistance and toluene resistance, which comprises the following components in parts by weight: polyisocyanate: 21.2-46.3 parts; limonene-based branched polyol: 53.3-77.9 parts; organotin catalyst: 0.3 parts ~1 part; organic solvent: 25~60 parts. Dissolving limonene-based branched polyol and polyisocyanate in an organic solvent, adding an organotin catalyst, mixing evenly, and vacuum drying at 30-150° C. for 2-6 hours to obtain the product. The present invention utilizes the activity difference between the double bond in the limonene ring and the double bond outside the ring to prepare limonene-based branched polyols with different functionalities through a two-step mercapto-ene addition reaction, and then react with polyisocyanate to convert the limonene structure A large amount of alicyclic six-membered rings are introduced into the main chain of polyurethane, and the resulting polyurethane has good mechanical properties and water and solvent resistance. The preparation method of the invention is simple and the reaction conditions are mild.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Method for preparing polyester modified organic silicon resin and coating containing the resin

ActiveCN102504265BLower surface energyLow surface energy coatings with good heat resistanceCoatingsPolyesterSilanes

The present invention relates to a method for preparing polyester modified organic silicon resin which is prepared from 45-75 wt% of saturated polyester, 1-10 wt% of 3-glycidyl ether oxygen propyl trimethoxy silane and 20-45 wt% of organic silicon resin by reacting. The acid value of the saturated polyester is within a range of 60 to 120 mgKOH / g, and the weight-average molecular weight of the saturated polyester is within a range of 2000 to 6000. The weight-average molecular weight of an intermediate of the organic silicon resin is within a range of 800 to 2000, the content of alkoxy of the organic silicon resin is within a range of 2.5 to 15%, and the content of hydroxyl of the organic silicon resin is within a range of 3 to 20%. By combining with advantages of saturated polyester and organic silicon resin, the method has advantages of excellent heat resistant quality, good metal adhesion, low surface energy, excellent boiling resistant quality and acid-alkali resistant quality, and good temperature variation resistant quality. The polyester modified organic silicon resin prepared by the method can be used for preparing a high temperature resistant coating with low surface energy.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Optical film having excellent water resistance and solvent resistance, and polarization plate comprising same

ActiveUS10662306B2Good water and solvent resistanceGood solvent resistanceSynthetic resin layered productsPolarising elementsPolymer resinOptical thin film

Disclosed are an optical film, including: a transparent film, and a coating layer on at least one surface of the transparent film, in which the coating layer is formed using a composition including a polymer resin, a dihydrazide-based crosslinking agent, and water-dispersible fine particles, and a polarizing plate including the same.

Owner:ANHUI HEMEI MATERIALS TECH CO LTD

Ink water dispersible quick-drying low temperature self-crosslinking acrylate resin and preparation method thereof

Owner:SOUTH CHINA UNIV OF TECH

Polymer particle, polymer dispersion, method for producing said polymer dispersion, coating material produced from said polymer dispersion, and coated article

InactiveUS20180105688A1Excellent characteristicsImprove stabilityPolyurea/polyurethane coatingsEmulsionPolymer science

A method for producing a polymer dispersion, by polymerizing a mixture X containing a urethane resin (A3), a monomer (b5) having two or more radically polymerizable groups, and a radically polymerizable monomer (b6) other than the monomer (b5), to obtain a dispersion containing a polymer P; and adding a pre-emulsion prepared by emulsifying and dispersing a radically polymerizable monomer mixture Y dropwise to the dispersion containing the polymer P and conducting polymerization, to obtain a dispersion containing a polymer Z, where a content of the urethane resin (A3) in the mixture X at the time of starting the reaction in the step (1) is from 25 to 95% by mass with respect to a total mass of the mixture X.

Owner:MITSUBISHI CHEM CORP +1

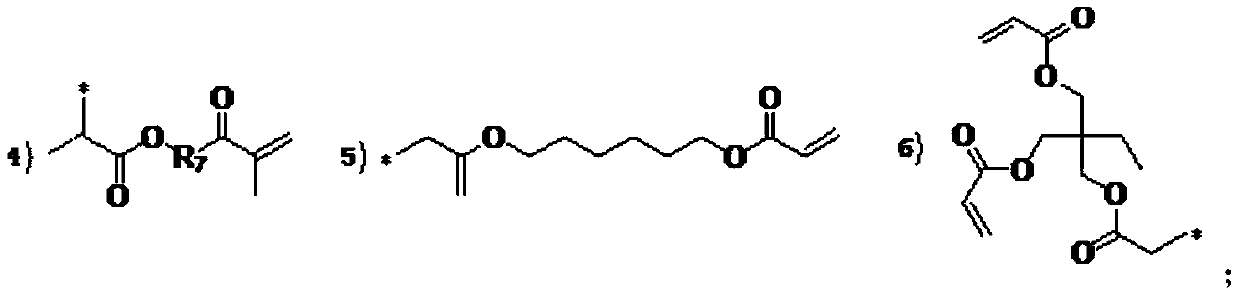

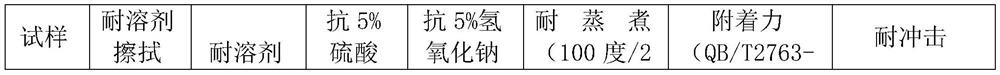

UV curing ink for aluminum plate and preparation method of UV curing ink

The invention discloses UV curing ink for an aluminum plate and a preparation method of the UV curing ink, belonging to the technical field of UV curing ink. The UV curing ink comprises, in parts by weight, 55 to 70 parts of unsaturated resin, 20 to 30 parts of acrylate monomers, 1 to 10 parts of a photoinitiator, 5 to 10 parts of a pigment and 1 to 5 parts of an auxiliary agent. According to theinvention, the UV curing ink with excellent comprehensive performance is obtained by adjusting the types and proportions of the soft and hard acrylate monomers. The ink is environment-friendly and non-toxic and has a high curing rate; epoxy groups in epoxy resin have excellent adhesive force to aluminum products; the ink is excellent in water resistance, solvent resistance, heat resistance, weather resistance and wear resistance after being cured; and the UV curing ink prepared in the invention can be attached to the surface of a metal product, and is especially suitable for roller coating tothe surface of a steel product.

Owner:安徽映山红材料科技有限公司

Stain-free water-based industrial guardrail paint

InactiveCN112280460AImprove wear resistanceHigh hardnessAntifouling/underwater paintsPaints with biocidesPolymer sciencePolyethylene glycol

The invention relates to a stain-free water-based industrial guardrail paint, an acrylic polyurethane emulsion is selected and matched with water-based epoxidized soybean oil modified alkyd resin anda propylene glycol ethyl ether film-forming agent, the obtained paint has excellent wear resistance and hardness, a polyurea curing agent is used, and the paint has the ultra-fast drying characteristic and has excellent water resistance and solvent resistance; and self-cleaning performance is good. In order to further improve the self-cleaning performance of the paint, polyethylene glycol is further added, although the proportion of polyethylene glycol in a paint film is not high, polyethylene glycol is matched with a polyurea curing agent, the water contact angle of the paint film can be remarkably increased, and therefore the better hydrophobic effect is achieved.

Owner:湖州汇邦环保科技有限公司

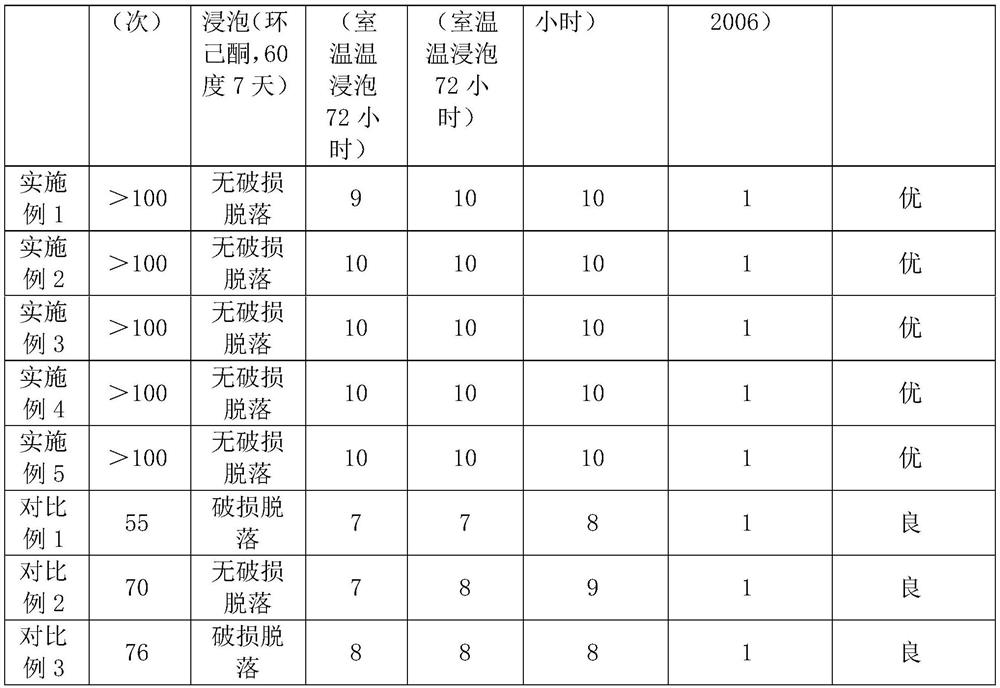

Preparation method of modified organic silicon resin and paint containing prepared modified organic silicon resin

The invention relates to the field of organic high molecular compounds, and particularly relates to a preparation method of modified organic silicon resin. The method comprises the following steps: sequentially heating 40-60w% of amino-terminated hyperbranched polyamide, 1-10w% of epoxy resin and 30-50w% of organic silicon resin along with a crosslinking catalyst accounting for 1-10w% of the amino-terminated hyperbranched polyamide respectively at 110-120 DEG C, 150-170 DEG C and 200-210 DEG C for 1-3 hours; and finally cooling to room temperature, and adding an organic solvent to regulate the solid content to 60-70%. The method combines the advantages of the hyperbranched polyamide, the epoxy resin and the organic silicon resin, and achieves excellent heat resistance, favorable metal adhesion, low surface energy and excellent water boiling resistance and alkaline resistance. The modified organic silicon resin prepared by the method can be used for preparing a high-temperature-resistant low-surface-energy paint.

Owner:SOUTHERN MEDICAL UNIVERSITY

A kind of high-strength cellulose/lignin composite material with reinforced concrete structure and its preparation method

ActiveCN107042559BSimple preparation processImprove efficiencyFibreboardWood treatment detailsCelluloseAlcohol

The invention discloses a high-strength cellulose / lignin composite material with a reinforced concrete structure and a preparation method thereof. The preparation method comprises the following steps that (1) a timber is cut into a wood chip in a needed specific shape; (2) the wood chip is soaked in a reaction kettle containing sodium sulfite, sodium hydroxide and methyl alcohol cooking liquid to be cooked; and (3) the cooked wood chip is washed with clean water, residual cooking liquid is removed, pressurization and drying are conducted, and the high-strength cellulose / lignin composite material with the reinforced concrete structure is obtained. The composite material has the reinforced concrete structure, and the tensile strength is as high as 810 MPa and is twenty times that of an original wood chip. The preparation method is simple in process, any non-biodegradable substances and environmentally harmful substances do not need to be added in the preparation process, and the preparation method is high in efficiency and environmentally friendly.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com