Method for preparing polyester modified organic silicon resin and coating containing the resin

A polyester modification, silicone technology, applied in the direction of coating, can solve the problems of high price and inconvenient construction, and achieve the effect of high pigment affinity, good adhesion, good water resistance and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

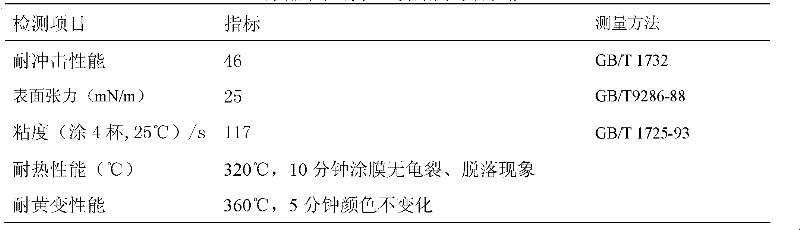

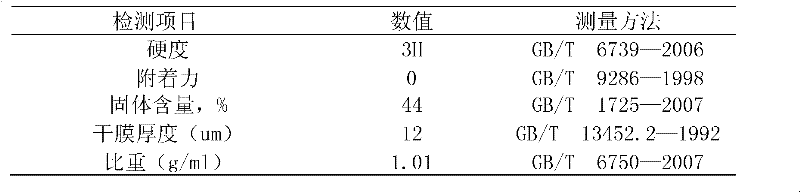

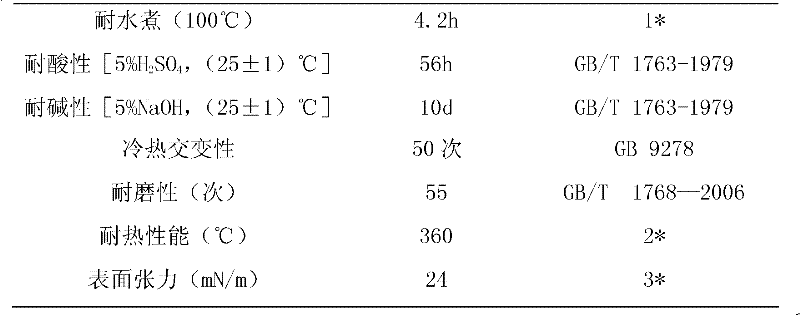

Examples

Embodiment 1

[0039] 1) Synthesis of saturated polyester

[0040] a) Composition:

[0041] Polyols: 62.4g (0.6mol) of neopentyl glycol; 27g (0.3mol) of 2-methyl-1,3 propanediol; 13.4g (0.1mol) of trimethylolpropane;

[0042] Dibasic acid: 132.8g (0.8mol) of isophthalic acid;

[0043] Dimethylol alkyl carboxylic acid: dimethylol propionic acid 6.7g (0.05mol);

[0044] b) synthesis steps:

[0045] Add polyol and dimethylol alkyl carboxylic acid into a reactor equipped with heating, condensation and nitrogen protection, and raise the temperature to 160°C under nitrogen protection; then add dibasic acid and heat to 240°C at a heating rate of 20°C per hour , keep warm for 4h; finally cool down to room temperature to obtain 215g saturated polyester.

[0046] c) Properties of saturated polyester

[0047] The hydroxyl value of the saturated polyester was detected according to the method described in GB / T7193.2-1987, and the result was 80mgKOH / g. The weight average molecular weight of the satur...

Embodiment 2

[0076] 1) Synthesis of saturated polyester

[0077] a) Composition:

[0078] Polyols: 62.4g (0.6mol) of neopentyl glycol; 27g (0.3mol) of 2-methyl-1,3 propanediol; 13.4g (0.1mol) of trimethylolpropane;

[0079] Dibasic acid: 132.8g (0.8mol) of isophthalic acid;

[0080] Dimethylol alkyl carboxylic acid: dimethylol propionic acid 13.4g (0.1mol);

[0081] b) synthesis steps:

[0082] Add polyol and dimethylol alkyl carboxylic acid into a reactor equipped with heating, condensation and nitrogen protection, and raise the temperature to 160°C under nitrogen protection; then add dibasic acid and heat to 240°C at a heating rate of 20°C per hour , keep warm for 4h; finally cool down to room temperature to obtain 213g of saturated polyester.

[0083] c) Properties of saturated polyester

[0084] The hydroxyl value of the saturated polyester was detected according to the method described in GB / T7193.2-1987, and the result was 120mgKOH / g. The weight average molecular weight of the s...

Embodiment 3

[0108] 1) Synthesis of saturated polyester

[0109] a) Composition:

[0110] Polyols: 62.4g (0.6mol) of neopentyl glycol; 27g (0.3mol) of 2-methyl-1,3 propanediol; 13.4g (0.1mol) of trimethylolpropane;

[0111] Dibasic acid: 99.6g (0.6mol) of isophthalic acid; 49.8g (0.3mol) of terephthalic acid

[0112] Dimethylol alkyl carboxylic acid: dimethylol propionic acid 6.7g (0.05mol); dimethylol acetic acid 12g (0.01mol); dimethylol butyric acid 1.48g (0.01mol);

[0113] b) synthesis steps:

[0114] Add polyol and dimethylol alkyl carboxylic acid into a reactor equipped with heating, condensation and nitrogen protection, and raise the temperature to 160°C under nitrogen protection; then add dibasic acid and heat to 240°C at a heating rate of 20°C per hour , keep warm for 4h; finally cool to room temperature to obtain 200g saturated polyester.

[0115] c) Properties of saturated polyester

[0116] The hydroxyl value of the saturated polyester was detected according to the method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com