High-resistance environment-friendly water-based coating for inner wall of packaging barrel and preparation method

A water-based coating, an environmentally friendly technology, applied in the field of coatings, to achieve the effect of convenient operation and control, high social value and ecological value, and excellent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

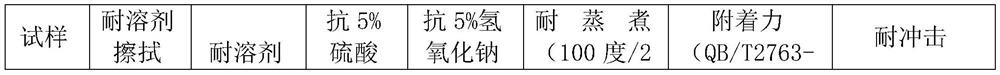

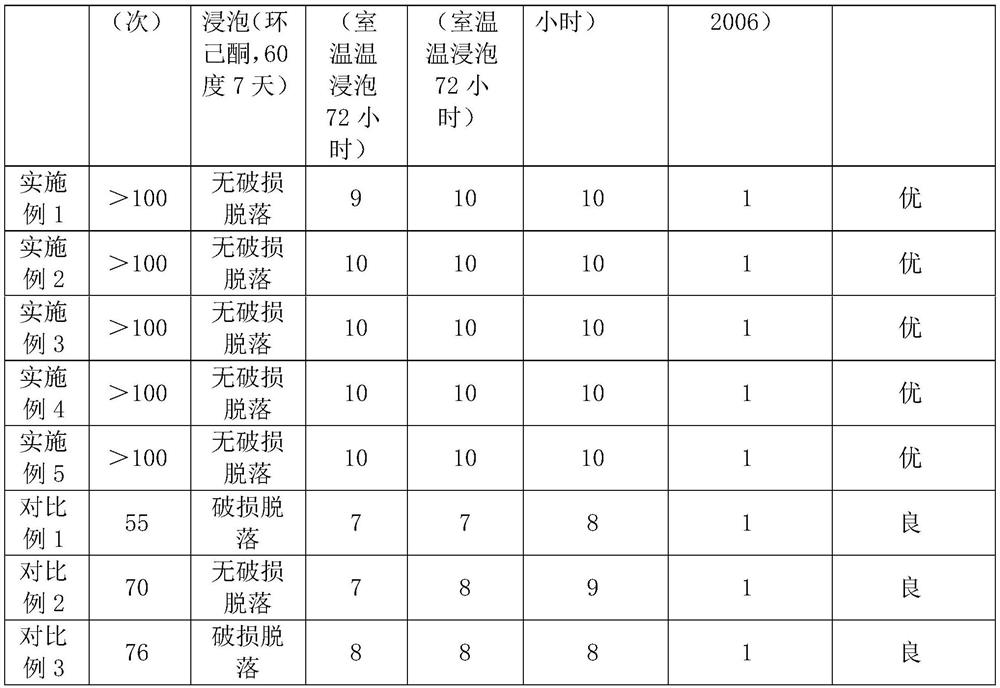

Examples

preparation example Construction

[0024] A method for preparing a water-based paint for the inner wall of a high-resistance environment-friendly packaging drum, characterized in that it comprises the following steps:

[0025] Step S1. Modified epoxy resin: Add epoxy resin to alcohol ether solvent, stir at 100-110°C until completely dissolved, then cool down to 75-85°C; then keep warm and stir, add modified while stirring After adding the agent, gradually raise the temperature to 115-120°C, heat and stir for 3.5-4 hours, then cool down to 40-60°C and discharge for later use;

[0026] Step S2, disperse the grinding powder: mix the modified epoxy resin, alcohol ether solvent, dispersant, and defoamer prepared in step S1, and stir evenly, then add titanium dioxide and iron yellow powder to it, and stir to disperse 20-40 minutes, then sand mill until the particle size is less than 5 μm, and use it as a slurry for later use;

[0027] Step S3, neutralization and compounding: mix the amine neutralizer and deionized w...

Embodiment 1

[0041] Embodiment 1 provides a kind of preparation method of water-based coating on the inner wall of highly resistant environment-friendly packaging drum, it is characterized in that, comprises the steps:

[0042] Step S1, modified epoxy resin: add epoxy resin to alcohol ether solvent, stir at 100°C until completely dissolved, then cool down to 75°C; After that, gradually raise the temperature to 115°C, heat and stir for 3.5 hours, then cool down to 40°C and discharge for later use;

[0043] Step S2, disperse the grinding powder: mix the modified epoxy resin, alcohol ether solvent, dispersant, and defoamer prepared in step S1, and stir evenly, then add titanium dioxide and iron yellow powder to it, and stir to disperse After 20 minutes, sand mill until the particle size is less than 5 μm, and use it as a slurry for later use;

[0044] Step S3, neutralization and compounding: mix the amine neutralizer and deionized water evenly, add the modified epoxy resin made in step S1, a...

Embodiment 2

[0054] Embodiment 2 provides a water-based paint for the inner wall of a high-resistance environment-friendly packaging barrel, its formula and preparation method are basically the same as in Embodiment 1, the difference is that the epoxy resin, alcohol ether solvent, and modifier described in step S1 The mass ratio is 49:43.5:5.0; the mass ratio of modified epoxy resin, alcohol ether solvent, dispersant, defoamer, titanium dioxide, iron yellow powder described in step S2 is 20.5:11.0:0.38:0.29: 41.5:20.5; the mass ratio of the amine neutralizer, deionized water, modified epoxy resin, and slurry described in step S3 is 1.15:35.5:23.5:29.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com