Water-based industrial fence paint

An industry and guardrail technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor chemical resistance, low solid content, and insufficient hardness of the paint film, and achieve excellent water and solvent resistance, excellent wear resistance and Good hardness and self-cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

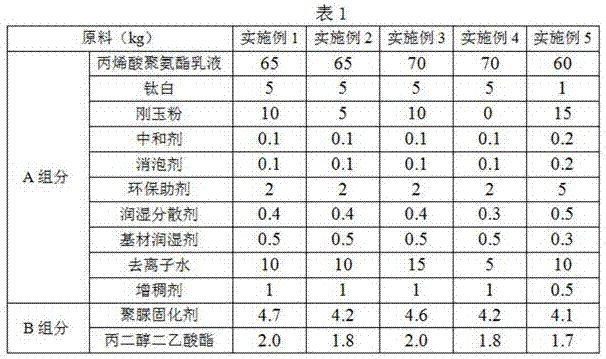

Examples

Embodiment 1

[0039] The water-based industrial guardrail paint obtained in Example 1 has good wear resistance and quick-drying properties, high hardness, the pencil hardness is H, has certain protective performance, and the drying time is 30 minutes.

Embodiment 2

[0040] The water-based industrial guardrail paint prepared in Example 2 is low in cost and has good wear-resistant and quick-drying properties. The pencil hardness is HB-H, has certain protective properties, and the drying time is 35 minutes.

Embodiment 3

[0041] The water-based industrial guardrail paint obtained in Example 3 has very good fast-drying and wear-resistant properties. Because of other examples, the pencil hardness is up to 2H, has the best protective properties and higher water and solvent resistance, and is the most cost-effective. The drying time is 15 minutes .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com